Abstract

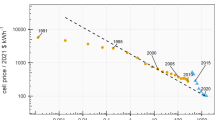

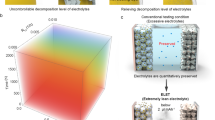

Cost and performance analysis is a powerful tool to support material research for battery energy storage, but it is rarely applied in the field and often misinterpreted. Widespread use of such an analysis at the stage of material discovery would help to focus battery research on practical solutions. When correctly used and well detailed, it can effectively direct efforts towards selecting appropriate materials for commercial applications. Using sodium-ion batteries as an example, we simulate the energy density and the cost of battery packs with several sodium-ion cathode materials taken from the literature in three case studies that illustrate how to identify the most promising solutions from the results of the model. Using publicly available information on material properties and open-source software, we demonstrate how a battery cost and performance analysis could be implemented using typical data from laboratory-scale studies on new energy storage materials.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Mauler, L., Duffner, F. & Leker, J. Economies of scale in battery cell manufacturing: the impact of material and process innovations. Appl. Energy 286, 116499 (2021).

Duffner, F., Wentker, M., Greenwood, M. & Leker, J. Battery cost modeling: a review and directions for future research. Renew. Sustain. Energy Rev. 127, 109872 (2020).

Meister, P. et al. Best practice: performance and cost evaluation of lithium ion battery active materials with special emphasis on energy efficiency. Chem. Mater. 28, 7203–7217 (2016).

Greenwood, M., Wentker, M. & Leker, J. A bottom-up performance and cost assessment of lithium-ion battery pouch cells utilizing nickel-rich cathode active materials and silicon–graphite composite anodes. J. Power Sources Adv. 9, 100055 (2021).

Vaalma, C., Buchholz, D., Weil, M. & Passerini, S. A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 3, 18013 (2018).

Mauler, L., Duffner, F., Zeier, W. G. & Leker, J. Battery cost forecasting: a review of methods and results with an outlook to 2050. Energy Environ. Sci. 14, 4712–4739 (2021).

Moon, H. et al. Bio-waste-derived hard carbon anodes through a sustainable and cost-effective synthesis process for sodium-ion batteries. ChemSusChem 16, e202201713 (2023).

Yalman, E. et al. Optimization of electrochemical presodiation parameters of Na‐ion full cells for stable solid–electrolyte interface formation: hard carbon rods from waste firefighter suits. Energy Technol. 11, 2300014 (2023).

Zhang, R. et al. Long-life lithium-ion batteries realized by low-Ni, Co-free cathode chemistry. Nat. Energy 8, 695–702 (2023).

Innocenti, A. et al. Practical cell design for PTMA-based organic batteries: an experimental and modeling study. ACS Appl. Mater. Interfaces https://doi.org/10.1021/acsami.3c11838 (2023).

Johansson, P. et al. Ten ways to fool the masses when presenting battery research. Batter. Supercaps 4, 1785–1788 (2021).

Dunn, B., Kamath, H. & Tarascon, J.-M. Electrical energy storage for the grid: a battery of choices. Science 334, 928–935 (2011).

Schmuch, R., Wagner, R., Hörpel, G., Placke, T. & Winter, M. Performance and cost of materials for lithium-based rechargeable automotive batteries. Nat. Energy 3, 267–278 (2018).

Greim, P., Solomon, A. A. & Breyer, C. Assessment of lithium criticality in the global energy transition and addressing policy gaps in transportation. Nat. Commun. 11, 4570 (2020).

Zuo, W. et al. Layered oxide cathodes for sodium-ion batteries: storage mechanism, electrochemistry, and techno-economics. Acc. Chem. Res. 56, 284–296 (2023).

Tian, Y. et al. Promises and challenges of next-generation ‘beyond Li-ion’ batteries for electric vehicles and grid decarbonization. Chem. Rev. 121, 1623–1669 (2021).

Duffner, F. et al. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nat. Energy 6, 123–134 (2021).

Roberts, S. & Kendrick, E. The re-emergence of sodium ion batteries: testing, processing, and manufacturability. Nanotechnol. Sci. Appl. 11, 23–33 (2018).

Tapia-Ruiz, N. et al. 2021 roadmap for sodium-ion batteries. J. Phys. Energy 3, 031503 (2021).

Manthiram, A., Fu, Y., Chung, S.-H., Zu, C. & Su, Y.-S. Rechargeable lithium–sulfur batteries. Chem. Rev. 114, 11751–11787 (2014).

Zhu, K. et al. How far away are lithium–sulfur batteries from commercialization? Front. Energy Res. 7, 123 (2019).

Maroni, F., Dongmo, S., Gauckler, C., Marinaro, M. & Wohlfahrt-Mehrens, M. Through the maze of multivalent‐ion batteries: a critical review on the status of the research on cathode materials for Mg2+ and Ca2+ ions insertion. Batter. Supercaps 4, 1221–1251 (2021).

Elia, G. A. et al. An overview and prospective on Al and Al-ion battery technologies. J. Power Sources 481, 228870 (2021).

Zhang, L., Wang, H., Zhang, X. & Tang, Y. A review of emerging dual‐ion batteries: fundamentals and recent advances. Adv. Funct. Mater. 31, 2010958 (2021).

Zhao, X., Zhao-Karger, Z., Fichtner, M. & Shen, X. Halide-based materials and chemistry for rechargeable batteries. Angew. Chem. Int. Ed. 59, 5902–5949 (2020).

Liang, Y. & Yao, Y. Positioning organic electrode materials in the battery landscape. Joule 2, 1690–1706 (2018).

Lu, Y. & Chen, J. Prospects of organic electrode materials for practical lithium batteries. Nat. Rev. Chem. 4, 127–142 (2020).

Esser, B. et al. A perspective on organic electrode materials and technologies for next generation batteries. J. Power Sources 482, 228814 (2021).

Rudola, A. et al. Commercialisation of high energy density sodium-ion batteries: Faradion’s journey outlook. J. Mater. Chem. A 9, 8279–8302 (2021).

CATL. CATL unveils its latest breakthrough technology by releasing its first generation of sodium-ion batteries. CATL https://www.catl.com/en/news/665.html (2021).

Sapunkov, O., Pande, V., Khetan, A., Choomwattana, C. & Viswanathan, V. Quantifying the promise of ‘beyond’ Li–ion batteries. Transl. Mater. Res. 2, 045002 (2015).

Grande, L. et al. The lithium/air battery: still an emerging system or a practical reality? Adv. Mater. 27, 784–800 (2015).

Raccichini, R., Varzi, A., Wei, D. & Passerini, S. Critical insight into the relentless progression toward graphene and graphene-containing materials for lithium-ion battery anodes. Adv. Mater. 29, 1603421 (2017).

Parker, J. F., Ko, J. S., Rolison, D. R. & Long, J. W. Translating materials-level performance into device-relevant metrics for zinc-based batteries. Joule 2, 2519–2527 (2018).

Wentker, M., Greenwood, M. & Leker, J. A bottom-up approach to lithium-ion battery cost modeling with a focus on cathode active materials. Energies 12, 504 (2019).

Knehr, K., Kubal, J., Nelson, P. & Ahmed, S. Battery performance and cost modeling for electric-drive vehicles: a manual for BatPaC v5.0 (US Department of Energy, 2022).

Knehr, K. W., Kubal, J. J., Deva, A., Effat, M. B. & Ahmed, S. From material properties to device metrics: a data-driven guide to battery design. Energy Adv. 2, 1326–1350 (2023).

Belt, J. R. Battery test manual for plug-in hybrid electric vehicles (US Department of Energy, 2010).

Christophersen, J. P. Battery test manual for electric vehicles (US Department of Energy, 2015).

Manthiram, A. A reflection on lithium-ion battery cathode chemistry. Nat. Commun. 11, 1550 (2020).

Xie, F., Xu, Z., Guo, Z. & Titirici, M.-M. Hard carbons for sodium-ion batteries and beyond. Prog. Energy Combust. Sci. 2, 042002 (2020).

Moon, H. et al. Assessing the reactivity of hard carbon anodes: linking material properties with electrochemical response upon sodium‐ and lithium‐ion storage. Batter. Supercaps 4, 960–977 (2021).

Asenbauer, J. et al. The success story of graphite as a lithium-ion anode material — fundamentals, remaining challenges, and recent developments including silicon (oxide) composites. Sustain. Energy Fuels 4, 5387–5416 (2020).

Fang, S., Bresser, D. & Passerini, S. Transition metal oxide anodes for electrochemical energy storage in lithium‐ and sodium‐ion batteries. Adv. Energy Mater. 10, 1902485 (2020).

Lakraychi, A. E., Dolhem, F., Vlad, A. & Becuwe, M. Organic negative electrode materials for metal‐ion and molecular‐ion batteries: progress and challenges from a molecular engineering perspective. Adv. Energy Mater. 11, 2101562 (2021).

Zarrabeitia, M. et al. Role of the voltage window on the capacity retention of P2-Na2/3[Fe1/2Mn1/2]O2 cathode material for rechargeable sodium-ion batteries. Commun. Chem. 5, 11 (2022).

Yadav, P., Shelke, V., Patrike, A. & Shelke, M. Sodium-based batteries: development, commercialization journey and new emerging chemistries. Oxf. Open Mater. Sci. 3, itac019 (2023).

Kim, J. et al. Unexpected discovery of low-cost maricite NaFePO4 as a high-performance electrode for Na-ion batteries. Energy Environ. Sci. 8, 540–545 (2015).

Kuze, S. et al. Development of a sodium ion secondary battery. Sumitomo Chemical https://www.sumitomo-chem.co.jp/english/rd/report/files/docs/03_2013e.pdf (2013).

Bianchini, M., Xiao, P., Wang, Y. & Ceder, G. Additional sodium insertion into polyanionic cathodes for higher-energy Na-ion batteries. Adv. Energy Mater. 7, 1700514 (2017).

Liu, Z. et al. Recent progress of P2‐type layered transition‐metal oxide cathodes for sodium‐ion batteries. Chemistry 26, 7747–7766 (2020).

Kulkarni, P. et al. A comprehensive review of pre-lithiation/sodiation additives for Li-ion and Na-ion batteries. J. Energy Chem. 76, 479–494 (2023).

Zou, K. et al. Prelithiation/presodiation techniques for advanced electrochemical energy storage systems: concepts, applications, and perspectives. Adv. Funct. Mater. 31, 2005581 (2021).

Huang, Z. et al. Progress and challenges of prelithiation technology for lithium‐ion battery. Carbon Energy 4, 1107–1132 (2022).

Yang, C. et al. Roll-to-roll prelithiation of lithium-ion battery anodes by transfer printing. Nat. Energy 8, 703–713 (2023).

Sathiya, M. et al. Dual stabilization and sacrificial effect of Na2CO3 for increasing capacities of Na-ion cells based on P2-NaxMO2 electrodes. Chem. Mater. 29, 5948–5956 (2017).

Shanmukaraj, D. et al. Highly efficient, cost effective, and safe sodiation agent for high-performance sodium-ion batteries. ChemSusChem 11, 3286–3291 (2018).

Niu, Y.-B. et al. High-efficiency cathode sodium compensation for sodium-ion batteries. Adv. Mater. 32, e2001419 (2020).

Fernández-Ropero, A. J. et al. Improved sodiation additive and its nuances in the performance enhancement of sodium-ion batteries. ACS Appl. Mater. Interfaces 13, 11814–11821 (2021).

Hasa, I., Passerini, S. & Hassoun, J. Toward high energy density cathode materials for sodium-ion batteries: investigating the beneficial effect of aluminum doping on the P2-type structure. J. Mater. Chem. A 5, 4467–4477 (2017).

Hasa, I., Passerini, S. & Hassoun, J. A rechargeable sodium-ion battery using a nanostructured Sb–C anode and P2-type layered Na0.6Ni0.22Fe0.11Mn0.66O2 cathode. RSC Adv. 5, 48928–48934 (2015).

Shellikeri, A. et al. Investigation of pre-lithiation in graphite and hard-carbon anodes using different lithium source structures. J. Electrochem. Soc. 164, A3914 (2017).

Li, X. et al. Review on comprehending and enhancing the initial Coulombic efficiency of anode materials in lithium-ion/sodium-ion batteries. Nano Energy 77, 105143 (2020).

Rajagopalan, R. et al. Improved reversibility of Fe3+/Fe4+ redox couple in sodium super ion conductor type Na3Fe2(PO4)3 for sodium-ion batteries. Adv. Mater. 29, 1605694 (2017).

Song, J. et al. Removal of interstitial H2O in hexacyanometallates for a superior cathode of a sodium-ion battery. J. Am. Chem. Soc. 137, 2658–2664 (2015).

Shanghai Metals Market. SMM spot metal prices. SMM https://www.metal.com (2024).

Baumann, M. et al. Prospective sustainability screening of sodium‐ion battery cathode materials. Adv. Energy Mater. 12, 2202636 (2022).

Acknowledgements

The authors thank the Helmholtz Association for basic funding.

Author information

Authors and Affiliations

Contributions

A.I. and S.P. conceived the idea. A.I. and S.B. read and summarized the relevant literature, carried out the simulations, analysed the results and visualized the data. A.I. wrote the original draft. S.P. revised the original draft, supervised the project and acquired the funding.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Reviews Materials thanks Jens Leker, Arumugam Manthiram, Stephan von Delft and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

In the Supplementary Information, it is possible to access: the data used as input for the simulations of the sodium-ion batteries; additional figures with the comparison of the energy density and the cost of battery packs and the voltage profiles before and after increasing the lower cut-off voltage; details on the implementation of the initial coulombic efficiency of anode and cathode and the use of sacrificial salt as pre-sodiation additive; the spreadsheets with all the relevant simulation results, the data analysis, as well as the original figures.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Innocenti, A., Beringer, S. & Passerini, S. Cost and performance analysis as a valuable tool for battery material research. Nat Rev Mater (2024). https://doi.org/10.1038/s41578-024-00657-2

Accepted:

Published:

DOI: https://doi.org/10.1038/s41578-024-00657-2