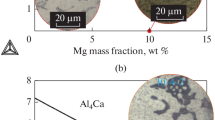

A new Al–Ca–Ce alloy system is investigated which is the basis for creating “natural composites” based upon aluminum. With the help of thermodynamic calculations and experimental studies of alloy structure and phase composition for all of the structure and elements of the composition diagram for an area rich in aluminum is proposed: projection of the liquidus surface and phase distribution in the solid state. The composition and structure of primary crystals of the phases Al4Ca and Al11Ce3 in equilibrium with an aluminum solid solution are studied using the XMRA and XPA methods, and mutual solubility of calcium and cerium within these phases is established with formation of compounds Al4(Ca,Ce) and Al11(Ce,Ca)3. Changes in primary crystal and eutectic microhardness as a result of calcium and cerium mutual solubility within them are investigated. Using nonequilibrium crystallization calculated data according to the Scheil–Gulliver model, in particular direct and differential thermal analyses, alloy critical temperatures and L → [(Al) + Al4Ca + Al11Ce3(Al4Ce)] ternary eutectic reaction temperature are calculated. Prospects for eutectic alloy Al6.5Ca3.5Ce as a high-tech heat-resistant “natural composite” are demonstrated.

Similar content being viewed by others

References

Yu. A. Gorbunov, “The role and prospects of rare earth metals in the development of physical-mechanical characteristics and applications of deformable aluminum alloys,” J. of Siberian Federal University. Engineering & Technologies, 5, No. 8, 636–645 (2015); https://doi.org/10.17516/1999-494X-2015-8-5-636-645.

V. M. Fedorov, “Some features of alloying aluminium alloys with transition metals under metastable crystallization conditions,” Aviats. Prom., No. 12, 42–45 (1990).

V. I. Dobatkin, V. I. Elagin, and V. M. Fedorov, “Alloying principles and composition regions of granulated aluminium alloys,” Tsvet. Met., No. 6, 33 (1993).

V. I. Dobatkin, V. I. Elagin, and V. M. Fedorov, “Granulated alumina alloys with special physical properties,” Aviats. Prom., No. 7, 55–57 (1990).

V. I. Dobatkin, V. I. Elagin, and V. M. Fedorov, Rapidly Crystallizing Aluminum Alloys [in Russian], VILS, Moscow (1995).

Z. C. Sims, O. R. Rios, D. Weiss, P. Turchi, A. Perron, J. Lee, T. Li, J. Hammons, M. Bagge-Hansen, T. M. Willey, K. An, Y. Chen, A. King, and S. McCall, “High performance aluminum–cerium alloys for high-temperature applications,” Mater. Horiz., 4, 1070–1078 (2017); https://doi.org/10.1039/c7mh00391a.

K. Ozturk, Chen Long-Qing, and Liu Zi-Kui, “Thermodynamic assessment of the Al–Ca binary system using random solution and associate models,” J. of Alloys and Compounds, No. 340, 199–206 (2002).

Zh. Zhanga, Y. Wangb, and X. Biana, “Microstructure selection map for rapidly solidified Al-rich Al–Ce alloys,” J. of Crystal Growth, No. 260, 557–565 (2004).

A. Hawksworth, W. M. Rainforth, and H. Jones, Solidification microstructure selection in the Al-rich Al–La, Al–Ce and Al–Nd systems,” J. of Crystal Growth, No. 197, 286–296 (1999).

G. Cacciamani and R. Ferro, “Thermodynamic modeling of some aluminium-rare earth binary systems: Al–La, Al–Ce and Al–Nd,” Calphad, 25, No. 4, 583–597 (2001).

Y. He, J. Liu, Sh. Qiu, Zh. Deng, J. Zhang, and Y. Shen, “Microstructure evolution and mechanical properties of Al–La alloys with varying La contents,” Materials Science & Engineering A, No. 701, 134–142 (2017).

Z. Cao, G. Kong, Ch. Che, Y. Wang, and H. Peng, “Experimental investigation of eutectic point in Al-rich Al–La, Al–Ce, Al–Pr and Al–Nd systems,” J. of Rare Earth, 35, No. 10, 1022 (2017).

N. A. Belov, A. N. Alabin, and D. G. Eskin, “Improving the properties of cold rolled Al–6%Ni sheets by alloying and heat treatment,” Scripta Materialia, 50, No. 1, 89–94 (2004).

N. A. Belov and V. S. Zolotorevskii, “Cast alloys based upon aluminium-nickel eutectic (nicalines) as a possible alternative to silumin,” Tsvet. Met., No. 2, 99–105 (2003).

P. K. Shurkin, N. V. Letyagin, A. I. Yakushkova, M. E. Samoshina, D. Y. Ozherelkov, and T. K. Akopyan, “Remarkable thermal stability of the Al–Ca–Ni–Mn alloy manufactured by laser powder bed fusion,” Materials Letters, 285, 129074 (2021).

N. A. Belov, E. A. Naumova, and D. G. Eskin, “Casting alloys of the Al–Ce–Ni system microstructural approach to alloy design,” Materials Science and Engineering. A. Structural Materials: Properties, Microstructure and Processing, A271, 134–142 (1999).

E. A. Naumova, “Study of the structure and properties of heat-resistant cast alloys based upon the aluminium-cerium system,” Tekhnol. Legkykh Splavov, No. 1 (2001).

I. I. Novikov, V. S. Zolotorevskii, V. K. Portnoi, N. A. Belov, D. V. Livanov, S. V. Medvedeva, A. A. Aksenov, and Yu. V. Evseev, Materials Science: Teaching Aid in 2 vol. Heat Treatment. Alloys [in Russian], MiSIS, Moscow (2009).

N. A. Belov, E. A. Naumova, and T. K. Akopyan, Eutectic Alloys Based Upon Aluminum: New Alloy Systems [in Russian], Ruda i Metally, Moscow (2016).

E. A. Naumova, “Use of calcium in alloys: from modifying to alloying,” Russian Journal of Non-Ferrous Metals, 59, No. 3, 284–298 (2018).

N. A. Belov, E. A. Naumova, T. K. Akopyan, and V. V. Doroshenko, “Design of multicomponent aluminium alloy containing 2 wt.% Ca and 0.1 wt.% Sc for cast products,” J. of Alloys and Compounds, 762, 528–536 (2018).

Information in site www.thermocalc.com; [Electronic resource].

E. V. Shelekhov and T. A. Sviridova, “Programs for X-ray analysis of polycrystals,” Met. Sci. Heat Treat., 42, 309–313 (2000); https://doi.org/10.1007/BF02471306.

L. F. Mondolfo, Aluminum Alloys: Structure and Properties, Butterworths, London (1976).

E. A. Naumova, N. A. Belov, and T. A. Bazlova, “Effect of heat treatment on structure and strengthening of cast eutectic aluminum alloy Al9Zn4Ca3Mg,” Metal Sci. Heat Treatment, 57, 1–7 (2015).

T. K. Akopyan, N. V. Letyagin, T. A. Sviridova, N. O. Korotkova, and A. S. Prosviryakov, “New casting alloys based on the Al +Al4(Ca,La) eutectic,” JOM, 72, No. 11, 3779–3786 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 9, pp. 49–57, September, 2023, Russian DOIhttps://doi.org/10.52351/00260827_2023_09_49.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Naumova, E.A., Vasina, M.A., Chernogorova, O.P. et al. Investigation of the Effect of Cerium on the Structure and Properties of Calcium-Containing Aluminum Alloys. Metallurgist 67, 1302–1314 (2024). https://doi.org/10.1007/s11015-024-01622-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01622-8