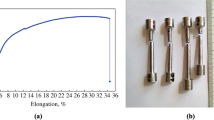

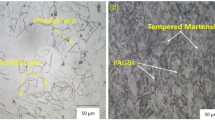

An austenitic metal-cored wire (diameter – 1.6 mm) with additional nitrogen alloying (0.25–0.40 wt.%) was developed for this study. Mechanical tests and metallographic studies of the deposited metal and welded joints made with austenitic metal-cored wire (composition – Cr20Mn5Ni4Mo2.5Cu3N0.3) were conducted. It was found that the values of σu and σ0.2 of the deposited metal obtained by using the developed wire were 20 to 30% higher compared to the utilized electrode materials, while the ductility characteristics were preserved (δ = 43%). It was shown that the use of metal-cored wire (Cr20Mn5Ni4Mo2.5Cu3N0.3) for welding of high-strength steel 20HGSNM (EN 1.6523) makes it possible to obtain defect-free welded joints with austenitic-ferritic structure, which have 20% higher strength characteristics compared to the analogues.

Similar content being viewed by others

References

T. A. Rakhmatullin, M. A. Sholokhov, and D. S. Buzorina, “Problems of implementing tapered grooves during welding of hull structures of special equipment,” Izv. Vuzov, No. 4, 64–66 (2012).

M. P. Shalimov, A. V. Berezovsky, and A. S. Smolentsev, “ Development of technology and powder wire for arc welding of highstrength alloyed steels,” Vestn. PNIPU, Mashinostroyenie, Materialovedenie, 21, No. 1, 49–54 (2019).

S. A. Gladyshov and V. A. Grigoryan, Armored Steels [in Russian], Intermet Engineering, Moscow (2010).

M. A. Sholokhov, S. A. Kurkin, and S. I. Poloskov, “Evaluation of the effect of groove shape and welding modes on residual stresses in structural components of special equipment,” Svarka i Diagnostika, No. 6, 50–55 (2014).

T. I. Tabatchikova, N. A. Tereshchenko, A. N. Morozova, and N. Z. Gudnev, “ Effect of intensive dynamic impact on phase and structural transformations in the metal of welded joints,” Fizika Metallov i Metallovedenie (FMM), 120, No. 6, 661–667 (2019).

A. V. Berezovsky, A. S. Smolentsev, M. P. Shalimov, M. S. Smolentsev, and A. N. Balin, “Current state and challenges of weldability of high-strength quench-hardening steels,” Tyazheloe Mashinostroyenie, No. 7-8, 2–9 (2021).

A. S. Smolentsev, “Ways to solve the weldability problems of high-strength steels prone to hardening (review),” Svarka i Diagnostika, No. 3, 48–53 (2019).

A. S. Smolentsev, “ New material for arc welding of high-strength medium-alloyed steels,” in: Welding, Renovation, Triboengineering: Materials of the 9th Ural Scientific and Practical Conference [in Russian], Nizhny Tagil: NTI (branch) of UrFU (2019), pp. 70–75.

N. P. Borovinskaya, V. I. Shumyakov, and G. S. Vasiliev, “New materials for welding armor,” Vest. Bronetank. Tekhn., No. 5, 45–47 (1977).

G. Magudeeswaran, V. Balasubramanian, and G. Madhusudan Reddy, “ Metallurgical characteristics of armour steel welded joints used for combat vehicle construction,” Defence Technology, No. 14, 590–606 (2018).

V. P. Korobko, P. B. Smirnov, N. Z. Gudnev, Yu. S. Korobov, V. I. Shumyakov, V. G. Shipsha, V. A. Bychenok, D. S. Ashikhin, V. Ye. Prokhorovich, I. Ye. Alifanova, I. A. Bespalov, A. V. Ilyin, P. V. Melnikov, A. N. Balin, and M. A. Sholokhov, “Brief description of the technology for obtaining new welding materials and welding technologies based on them for the manufacture of lightarmored vehicles with bulletproof welded joints at the base metal level for steels: St7, A3, and 44SVSh,” in: Relevant Problems of Protection and Safety: Proc. of the 22nd All-Russian Scientific and Practical Conference RARAN (April 1-4, 2019), Federal State Budgetary Institution “Russian Academy of Rocket and Artillery Sciences,” St. Petersburg (2019), pp. 127–136.

S. Ye. Aleksentseva, Impact-Wave Processes of High-Speed Elements Interaction with Condensed Media [in Russian], Abstract of the Dissertation (Doctor of Technical Sciences), Samara (2015).

R. Mohammed, M. Reddy, and K. Srinivasa Rao, “Welding of nickel free high nitrogen stainless steel: Microstructure and mechanical properties,” Defence Technology, 13, No. 2, 59–71 (2017).

B. Singh, G. P. Sukumar, S. Ponguru, P. Jena, R. Pochana, K. Kumar, V. Madhu, and G. Reddy, “Future armour materials and technologies for combat platforms,” Defence Sci. J., 67, 412 (2017).

V. V. Sagadze and A. I. Uvarov, Strengthening and Properties of Austenitic Steels [in Russian], RIO URO RAN, Yekaterinburg (2013).

L. M. Kaputkina, I. V. Smarigina, A. G. Svyazhin, V. E. Kindop, and Ye. V. Blinov, “Structural stability and properties of nitrogencontaining high-strength austenitic steels under cyclic thermal and mechanical loads,” MiTOM, No. 1 (763), 3–9 (2019).

I. V. Gorynin, V. A. Malyshevskii, G. Yu. Kalinin, S. Yu. Mushnikova, O. A. Bannykh, V. M. Blinov, and M. V. Kostina, “Corrosionresistant high-strength nitrogen-containing steels,” Voprosy Materialovedeniya, Central Research Institute of Structural Materials “Prometei,” St. Petersburg, No. 3 (59), 7–16 (2009).

I. O. Bannykh, “ Structural specifics and application prospects of high-nitrogen austenitic steels,” MiTOM, No. 5 (767), 22–29 (2019).

V. V. Berezovskaya and A. V. Berezovsky, Corrosion-Resistant Steels and Alloys [in Russian], Publ. Ural. Univ., Yekaterinburg (2019).

A. G. Svyazhin and L. M. Kaputkina, “Nitrogen and high-nitrogen steels: industrial technologies and properties,” Izv. Vuzov. Chernaya Metallurgiya, 62, No. 3, 173–187 (2019).

M. V. Kostina and L. G. Rigina, “Nitrogen-containing steels and methods of their production,” Izv. Vuzov. Chernaya Metallurgiya, 63, No. 8, 606–622 (2020).

Ts. V. Rashev, A. V. Yeliseev, L. T. Zhekova, and P. V. Bogev, “High-nitrogen steels,” Izv. Vuzov. Chernaya Metallurgiya, 62, No. 7, 503–510 (2019).

E. Goodremon, Special Steels [in Russian], in 2 vol., Vol. 2, transl. from German, ed. by A. S. Zaimovskii, corr. member of the USSR Academy of Sciences, Metallurgiya, Moscow (1966).

Copper in Ferrous Metals [in Russian], ed. by I. Le Mei and L. M.-D. Shetki, transl. from English by I. D. Marchukova and A. N. Shteynberg, ed. by O. A. Bannykh, Metallurgiya, Moscow (1988).

M. V. Pridantsev, N. P. Talov, and F. L. Levin, High-strength Austenitic Steels [in Russian], Metallurgiya, Moscow (1969).

S. R. Birman, Economically Alloyed Martensite-aging Steels [in Russian], Metallurgiya, Moscow (1974).

F. B. Pickering, Physical Metallurgy and the Design of Steels [in Russian], Metallurgiya, Moscow (1982).

F. B. Pickering, Physical Metallurgy and the Design of Steels, Applied Science Publisher Ltd, London (1978).

A. S. Smolentsev, “Strength characteristics of deposited metal and welded joints made with TWIP-austenitic powder wire,” in: 21st Int. Sci. Techn. Ural School-Seminar of Young Metallurgy Scientists [in Russian], Ural Federal University, Yekaterinburg (2022), pp. 400-405.

D. Lippold, Welding Metallurgy and Weldability of Stainless Steels [in Russian], transl. from English by N. A. Sosnin and A. M. Levchenko, Polytechn. Univ. Publ., St. Petersburg (2011).

T. I. Tabatchikova, A. D. Nosov, S. N. Goncharov, N. Z. Gudnev, S. Yu. Delgado Reina, and I. L. Yakovleva, “Structure and viscosity of the heat-affected zone of welded joints of high-strength steel,” Fizika Metallov i Metallovedenie, 115, No. 12, 1309–1317 (2014).

E. L. Makarov and B. F. Yakushin, Theory of Weldability of Steels and Alloys [in Russian], Bauman Moscow State Technical University Publ., Moscow (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 9, pp. 71–77, September, 2023. Russian https://doi.org/10.52351/00260827_2023_09_71

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Smolentsev, A.S., Veselova, V.E., Berezovsky, A.V. et al. Structure and Properties of Welded Joints of High-Strength Steels Made by Metal-Cored Wire with Nitrogen. Metallurgist 67, 1334–1343 (2024). https://doi.org/10.1007/s11015-024-01625-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01625-5