Abstract

This research aimed to showcase an economical and environmentally friendly approach to producing sandwich-structured composites from recycled plastics and krajood waste. The effects of the contents and particle sizes on mechanical and physical properties, including thermal conductivity and sound absorption coefficient, were investigated. The experimental results were analyzed using Analysis of Variance (ANOVA). The results confirmed that the isocyanate glue at 25% (by weight) and krajood fiber at 75% (by weight) at 40 mesh enhanced the flexural, compressive, and screw withdrawal properties the most. The increase in krajood fiber contents ranged from 75 to 85% (by weight) and increased the water absorption percentages. Core layer samples with high conductivity at 0.085 W/mK are considered suitable for building insulation applications, whereas sandwich composites at 0.189 W/mK are used for outdoor materials. In addition, the sound absorption coefficient and noise reduction coefficient were used to evaluate the application efficiency of sandwich-structured composite materials. The highest sound absorption coefficient and noise reduction coefficient were found using a sound frequency of 1000 Hz. The highest noise reduction coefficient value of 0.78 was found in the core layer sample, meaning that the sample absorbs 78% of sound and reflects the remaining 22% of sound waves back into a room. Thus, the outcomes of this study offer recommendations for the manufacture of sandwich composite materials from recycled polypropylene reinforced with krajood fiber in applications for construction and building products.

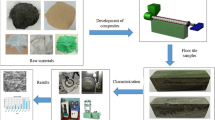

Graphical Abstract

Similar content being viewed by others

Data availability

The data availability statement will be made available on request.

References

Srivabut C, Homkhiew C, Rawangwong S, Boonchouytan W (2022) Possibility of using municipal solid waste for manufacturing wood-plastic composites: effects of natural weathering, wood waste types, and contents. J Mater Cycles Waste Manag 24:1407–1422. https://doi.org/10.1007/s10163-022-01443-4

Greenpeace Thailand (2021) Greenpeace is powered by people like you. (Accessed 22 Junly 2023) https://www.greenpeace.org/thailand

Kamdar I, Ali S, Bennui A, Techato K, Jutidamrongphan W (2019) Municipal solid waste landfill siting using an integrated GIS-AHP approach: A case study from Songkhla, Thailand. Resour Conserv Recycl 149:220–235. https://doi.org/10.1016/j.resconrec.2019.05.027

PCD (2019) Thailand state of pollution control report. (Accessed 23 July 2023) https://infofile.pcd.go.th/Waste/Wst2019.pdf

Chen B, Luo Z, Chen H, Chen C, Cai D, Qin P, Cao H, Tan T (2020) Wood plastic composites from the waste lignocellulosic biomass fibers of bio-fuels processes: A comparative study on mechanical properties and weathering effects. Waste Biomass Valori 11:1701–1710. https://doi.org/10.1007/s12649-018-0413-8

Homkhiew C, Srivabut C, Rawangwong S, Boonchouytan W (2022) Performance of wood-plastic composites manufactured from post-consumer plastics and wood waste under coastal weathering in Thailand. Fibers Polym 23:2679–2693. https://doi.org/10.1007/s12221-022-0014-9

Sommerhuber PF, Welling J, Krause A (2015) Substitution potentials of recycled HDPE and wood particles from post-consumer packaging waste in wood-plastic composites. Waste Manag 46:76–85. https://doi.org/10.1016/j.wasman.2015.09.011

Khamtree S, Ratanawilai T, Ratanawilai S (2020) The effect of alkaline-silane treatment of rubberwood flour for water absorption and mechanical properties of plastic composites. J Thermoplast Compos Mater 33:599–613. https://doi.org/10.1177/0892705718808556

Essabir H, Boujmal R, Bensalah MO, Rodrigue D, Bouhfid R, Qaiss A (2016) Mechanical and thermal properties of hybrid composites: oil-palm fiber/clay reinforced high density polyethylene. Mech Mater 98:36–43. https://doi.org/10.1016/j.mechmat.2016.04.008

Vinod A, Sanjay MR, Suchart S, Jyotishkumar P (2020) Renewable and sustainable biobased materials: An assessment on biofibers, biofilms, biopolymers and biocomposite. J Clean Prod 258:120978. https://doi.org/10.1016/j.jclepro.2020.120978

Ratanawilai T, Taneerat K (2018) Alternative polymeric matrices for wood-plastic composites: effects on mechanical properties and resistance to natural weathering. Constr Build Mater 172:349–357. https://doi.org/10.1016/j.conbuildmat.2018.03.266

Srivabut C, Ratanawilai T, Hiziroglu S (2018) Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr Build Mater 162:450–458. https://doi.org/10.1016/j.conbuildmat.2017.12.048

Alomayri T, Assaedi H, Shaikh FUA, Low IM (2014) Effect of water absorption on the mechanical properties of cotton fabric-reinforced geopolymer composites. J Asian Ceram Soc 2014:223–230. https://doi.org/10.1016/j.jascer.2014.05.005

Ratanawilai T, Nakawirot K, Deachsrijan A, Homkhiew C (2014) Influence of wood species and particle size on mechanical and thermal properties of wood polypropylene composites. Fibers Polym 15:2160–2168. https://doi.org/10.1007/s12221-014-2160-1

Ramnath BV, Alagarraja K, Elanchezhian C (2019) Review on sandwich composite and their applications. Mater Today Proc 16:859–864. https://doi.org/10.1016/j.matpr.2019.05.169

Yang J, Wu J, Zhou L, Wang O (2016) Computational study of fluid flow and heat transfer in composite packed beds of spheres with low tube to particle diameter ratio. Nucl Eng Des 300:85–96. https://doi.org/10.1016/j.nucengdes.2015.10.030

Radhakrishnan G, Mathialagan S (2022) Effect of fiber orientation on mechanical behavior of glass fiber reinforced polyethylene terephthalate foam sandwich composite. Mater Today Proc 62:624–628. https://doi.org/10.1016/j.matpr.2022.03.623

Cabrera NO, Alcock B, Peijs T (2008) Design and manufacture of all-PP sandwich panels based on co-extruded polypropylene tapes. Compos Part B Eng 39:1183–1195. https://doi.org/10.1016/j.compositesb.2008.03.010

Vinod A, Tengsuthiwat J, Gowda Y, Vijay R, Sanjay MR, Siengchin S, Dhakal HN (2022) Jute/Hemp bio-epoxy hybrid bio-composites: influence of stacking sequence on adhesion of fiber-matrix. Int J Adhes Adhes 113:103050. https://doi.org/10.1016/j.ijadhadh.2021.103050

Laraba SR, Rezzoug A, Halimi R, Wei L, Yang Y, Abdi S, Li Y, Jie W (2022) Development of sandwich using low-cost natural fibers: alfa-epoxy composite core and jute/metallic mesh-Epoxy hybrid skin composite. Ind Crops Prod 184:119053. https://doi.org/10.1016/j.indcrop.2022.115093

Karaduman Y, Onal L (2016) Flexural behavior of commingled jute/polypropylene nonwoven fabric reinforced sandwich composites. Compos Part B Eng 93:12–25. https://doi.org/10.1016/j.compositesb.2016.02.055

Kukreja R (2021) Effects of noise pollution on human health and animals, Uttar Pradesh, India. (Accessed 24 July 2023) https://www.conserve-energy-future.com/effects-noise-pollution-humans-health-animals.php

Cherradi Y, Rosca IC, Cerbu C, Kebir H, Guendouz A, Benyoucef M (2021) Acoustic properties for composite materials based on alfa and wood fibers. Appl Acoust 174:107759. https://doi.org/10.1016/j.apacoust.2020.107759

Xiang HF, Wang D, Liua HC, Zhao N, Xu J (2013) Investigation on sound absorption properties of kapok fibers. Chin J Polym Sci 31:521–529. https://doi.org/10.1007/s10118-013-1241-8

Taban E, Soltani P, Berardi U, Putra A, Mousavi SM, Faridan M, Samaei SE, Khavanin A (2020) Measurement, modeling, and optimization of sound absorption performance of Kenaf fibers for building applications. Build Environ 180:107087. https://doi.org/10.1016/j.buildenv.2020.107087

Tang X, Zhang X, Zhang H, Zhuang X, Yan X (2018) Corn husk for noise reduction: Robust acoustic absorption and reduced thickness. Appl Acoust 134:60–68. https://doi.org/10.1016/j.apacoust.2018.01.012

Berardi U, Iannace G, Di Gabriele M (2017) The acoustic characterization of broom fibers. J Nat Fib 14(6):858–863. https://doi.org/10.1080/15440478.2017.1279995

Berardi U, Iannace G (2015) Acoustic characterization of natural fibers for sound absorption applications. Build Environ 94:840–852. https://doi.org/10.1016/j.buildenv.2015.05.029

Sargianis JJ, Kim HI, Andres E, Suhr J (2013) Sound and vibration damping characteristics in natural material based sandwich composites. Compos Struct 96:538–544. https://doi.org/10.1016/j.compstruct.2012.09.006

Srivabut C, Khamtree S, Homkhiew C, Ratanawilai T, Rawangwong S (2023) Comparative effects of different coastal weathering on the thermal, physical, and mechanical properties of rubberwood-latex sludge flour reinforced with polypropylene hybrid composites. Composites Part C 12:100383. https://doi.org/10.1016/j.jcomc.2023.100383

Homkhiew C, Srivabut C, Ratanawilai T, Rawangwong S, Chantaramanee S (2023) Characterization of polypropylene composites using sludge waste from the natural rubber latex industry as reinforcing filler. J Mater Cycles Waste Manag 25:1444–1456. https://doi.org/10.1007/s10163-023-01621-y

Srivabut C, Ratanawilai T, Hiziroglu S (2019) Response surface optimization and statistical analysis of composites made from calcium carbonate filler-added recycled polypropylene and rubberwood fiber. J Thermoplast Compos Mater 35:391–416. https://doi.org/10.1177/0892705719889988

Krzyżak A, Mazur M, Gajewski M, Drozd K, Komorek A, Przybyłek P (2016) Sandwich structured composites for aeronautics: methods of manufacturing affecting some mechanical properties. Int J Aerosp Eng 2016:7816912. https://doi.org/10.1155/2016/7816912

Xian Y, Wang C, Wang G, Ren W, Cheng H (2015) Understanding the mechanical and interfacial properties of core–shell structured bamboo-plastic composites. Inc J Appl Polym Sci 133:43053. https://doi.org/10.1002/app.43053

Ashori A, Nourbakhsh A (2009) Characteristics of wood-fiber plastic composites made of recycled materials. Waste Manag 29:1291–1295. https://doi.org/10.1016/j.wasman.2008.09.012

Chen H, Xuan J, Deng O, Gao Y (2022) WOOD/PCM composite with enhanced energy storage density and anisotropic thermal conductivity. Prog Nat Sci: Mater 32:190–195. https://doi.org/10.1016/j.pnsc.2022.01.002

Prisco U (2014) Thermal conductivity of flat-pressed wood plastic composites at different temperatures and filler content. Sci Eng Compos Mater 21:197–204. https://doi.org/10.1515/secm-2013-0013

Zhang X, Zhang J, Wang R (2019) Thermal and mechanical behavior of wood plastic composites by addition of graphene nanoplatelets. Polymers 11(8):1365. https://doi.org/10.3390/polym11081365

Seo J, Park Y, Kim J, Kim S, Kim S, Kim JT (2014) Comparison of thermal transfer characteristics of wood flooring according to the installation method. Energy Build 70:422–426. https://doi.org/10.1016/j.enbuild.2013.11.085

Chen Q, Guo X, Ji F, Wang J, Wang J, Cao P (2015) Effects of decorative veneer and structure on the thermal conductivity of engineered wood flooring. BioResources. https://doi.org/10.15376/biores.10.2.2213-2222

Homkhiew C, Srivabut C, Boonchouytan W, Ratanawilai T, Rawangwong S (2023) Optimization of the physical properties of recycled plastic hybrid composites reinforced with rubberwood flour and crab shell flour for underwater use. Composites Part C 12:100411. https://doi.org/10.1016/j.jcomc.2023.100411

Acknowledgements

The authors gratefully acknowledge the financial support from the Thailand Science Research and Innovation (Research Grant Code: 66A171000025) and the Rajamangala University of Technology Srivijaya (RMUTSV), Thailand. We would also like to thank Mr. Jinnapat Phattaburee and Mr. Alongkon Siripeat for supporting this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Homkhiew, C., Srivabut, C., Boonchouytan, W. et al. Sandwich composites from recycled plastic reinforced with krajood (Lepironia articulata) fiber for building applications. Iran Polym J 33, 839–853 (2024). https://doi.org/10.1007/s13726-024-01292-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-024-01292-y