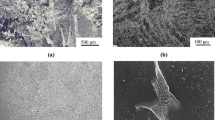

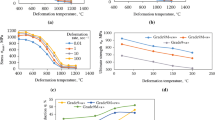

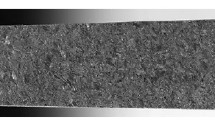

The article provides systematization and comparative analysis of data for structure, phase composition, physical and mechanical properties formed within deformed pipes of semifinished products in different stages of preparing cold rolled pipes from hot-rolled pipe billets of titanium alloys PT–1M, PT–7M, Ti–3Al–2.5V. The effect of the degree of cold deformation on strain hardening of specimens from alloy hot-extruded pipes of semifinished products of the test alloys is established and on the basis of this recommendations are developed for maximum acceptable degree of deformation during cold rolling of pipes made of PT–1M, PT–7M, Ti–3Al–2.5V alloys. Deformation warming of alloys during cold rolling is evaluated. It is shown that cold rolling of pipes of the alloys studied into intermediate and final pipe workpieces with the reduction recommended contributes to the pipe strain hardening. When simulating cold rolling of pipes calculation of the Q-factor is carried out, which has a value of about 1. Cold rolling with such a value of Q-factor leads to formation of a texture of an inclined tangential prism alloying alloy from PT–1M to Ti–3Al–2.5V. It is noted that intermediate and final annealing at 680°C (PT–1M alloy), 750°C (PT–7M alloy, Ti–3Al–2.5V) of cold-rolled pipe billets studied facilitates alloy loss of strength as a result of occurrence of recrystallization and to the formation of a two-component texture {0001}±φ°TD<10–10>RD and {0001}±φ°TD<11–20>RD. Features of structure formation, phase composition, and mechanical properties of pipes in relation to alloying are considered.

Similar content being viewed by others

References

D. A. Pumpyanskiy, “Problems of pipe market competitive development. Series of scientific papers” UrO RAN, Inst. Ekonomiki (Prep.) Ekaterinburg (2004).

D. A. Pumpyanskiy, “Pipe industry: selection of its niche. Export volume of seamless pipe leading tempo” Metally Evrazii, No. 4, 26–27 (2004).

D. A. Pumpyanskiy, A. G. Illarionov, F. V. Vodolazkiy, Ya. I. Kosmatskiy, and A. A. Popov, “Prospective titanium alloys for preparing cold-deformed pipes,” Metallurg, No. 1, 37–48 (2023).

S. S. Ushkov and B. B. Chechulin, “Experience in the field of titanium application in shipbuilding and off-shore structures,” Titan, No. 3-4, 38–40 (1995)..

A. A. Il’in, B. A. Kolachev, and I. S. Pol’kin, Titanium Alloys. Composition, Structure, Properties, Reference [in Russian], VILS, Moscow (2009).

Y. Zhao, “The new main titanium alloys used for shipbuilding developed in China and their applications,” Materials China, 33, No. 7, 398–404 (2014).

V. V. Tetyukhin, V. G. Smirnov, A. A. Fyodorov, and A. V. Safianov, “New titanium alloy development and tube manufacture for offshore oil and gas production,” Titanium 99 Sci. Technology, 2, 1119–1124 (1999).

V. G. Smirnov, B. G. Krokhin, and V. S. Kalinin, “Assimilation of the production of high quality pipe billets (TREX) of titanium alloys for aerospace systems,” Titan, No. 1 (12), 36–39 (2003).

V. V. Tetyukhin, V. G. Smirnov, and D. A. Krashennikov, “Contemporary technology and new solutions in the production of pipes and hollow forgings of titanium alloys,” Tekhnol. Legkikh Splavov, No. 4, 96–105 (2007).

V. P. Leonov, V. N. Kopylov. L. N. Ptishcheva, V. G. Smirnov, and M. V. Egorov, “Assimilation and features of technology for producing titanium pipes within Russian factories,” Voprosy Materialovedenie, No. 2 (78), 63–72 (2014).

Ya. I. Kosmatskiy, E. A. Filyaeva, N. V. Fokin, and K. Yu. Yakovleva, “Determination of the engineering possibility of preparing a new form of seamless pipes TREX from titanium alloy Ti-3Al-2.5V,” Kachestvo Obrabotke Materialov, No. 2 (6), 15–22 (2016).

E. A. Filyeva and Ya. I. Kosmatskiy, “Engineering features of titanium alloy pipe preparation,” Vestn. Yuzhno-Ural. Univ. Ser. Metallurgiya, 17, No. 2, 70–76 (2017).

A. S. Oryshchenko, V. P. Leonov, and V. I. Mikhailov, “Titanic work: 60 years of titanium development within Russia,” Innovatsi, No.7 (225), 7–10 (2017).

V. P. Leonov, L. P. Rtishcheva, V. N. Kopylov, et al., RF Patent 2648431, MPК B21B23/00, Production Method for Hot-Deformed Pipes with a Size of 8.0×1.5 mm, No. 2016141050; Claim 19.10.2016; Publ. 26.03.2018, Bull. 9.

I. Yu. Pyshmintsev, Ya. I. Kosmatskiy, E. A. Filyaeva, et al., RF Patent 2661125, MPК C22F 1/18, B21B 3/00, B21J, 5/00, Method for Preparing Seamless Cold-Deformed Pipes of Titanium Alloy Type Ti–3Al–2.5V, Claim 10.05.2017; Publ. 11.07.2018, Bull. 20.

A. S. Oryshchenko, V. P. Leonov, L. P. Ptitsov, V. N. Kopylov, and K. G. Martynov, “Contemporary state of the production and use of titanium alloy pipes in atomic power engineering and ship building,” Titan, No. 3 (61), 21–32 (2018).

Ya. I. Kosmatskiy, B. V. Barichko, K. Yu. Yakovleva, N. V. Fokin, and V. D. Nikolenko, “Results of studying compaction processes and cold deformation as a basis for assimilating new pipe production,” Stal’, No. 12, 39–42 (2020).

D. A. Pumpyanskiy, A. G. Illarionov, F. V. Vodolaskiy, Ya. I. Kosmatskiy, S. M. Illarionova, and A. A. Popov, “Material science aspects of titanium tube production. Part 1. Production of hot-extruded tubes,” Metallurg., No. 8, 30–40 (2023).

Ya. I. Kosmatskiy, B. V. Barichko, E. A. Filaeva, and K. Yu. Yakovleva, “Evaluation of the effect of cold deformation and heat treatment on formation and change of titanium alloy Ti–3Al–2.5V mechanical properties,” Titan, No. 4 (54), 39–44 (2016).

Yu. N. Loginov, A. Yu. Postylyakov, F. V. Vodolazkiy, and Ya. I. Kosmatskiy, “Deformation during titanium alloy pipe cold rolling,” Titan, No. 1 (77),49–53 (2023).

S. P. Belov, M. Ya. Brun, S. G. Glazunov, et al., Physical Metallurgy of Titanium and its Alloys [in Russian] Metallurgiya, Moscow (1992).

Q. Liao, C. Deng, H. Qu, Y. Yang, L. Nan, and J. Yang, “Effects of deformation rate on microstructure and tensile properties of cold rolled Ti–3Al–2.5V alloy tube,” Ti 2011 — Proceedings of the 12th World Conf. on Titanium, Science Press, Beijing (2012).

G. A. Orlov and A. G. Orlov, “Consideration of deformation warming during pipe cold rolling,” Izv. Vuzov. Chernaya Metallurgiya, 57, No. 9, 11–14 (2014).

G. A. Orlov, “Engineering evaluation of metal treatment capacity under pressure,” Izv. Vuzov. Chernaya Metallurgiya, 56, No. 3, 64–66 (2013).

C. G. Glazunov and V. N. Moiseev, Structural Titanium Alloys [in Russian], Metallurgy, Moscow (1974).

Titanium Alloy Guide (2000); www.RMITitanium.com.

Q. Yang, S. Hui, W. Ye, Z. Xu, C. Dai, and Y. Lin, “Effect of ‘Q’ ratio on texture evolution of Ti–3Al–2.5V alloy tube during rolling,” Materials, 15, 817 (2022); https://doi.org/https://doi.org/10.3390/ma15030817.

J. Gokyu, H. Suzuki, and F. Seki, “Studies on rolled and annealed textures in commercially pure Ti,” J. Inst. Metals. Metallurg. Abstr., 22, 195–196 (1954/55).

U. Tsvikker, Titanium and Its Alloys [in Russian], Mir, Moscow (1979).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 10, pp. 50–58, October, 2023. Russian DOI https://doi.org/10.52351/00260827_2023_10_50.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pumpyanskiy, D.A., Illarionov, A.G., Vodolazskiy, F.V. et al. Material Science Aspects of Titanium Tube Production. Part 2. Production of Cold-Rolled Tubes. Metallurgist 67, 1482–1493 (2024). https://doi.org/10.1007/s11015-024-01641-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01641-5