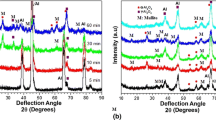

The structure and properties of coatings formed by plasma electrolytic oxidation (PEO) on as-cast Al–Ca alloy (7 wt.% Ca) and pure Al (99.99 wt.% Al) are studied. It is shown that substrates have a significant impact on the quality, structure and properties of a coating formed. According to SEM analysis results, presence of Ca within a substrate leads to an increase in coating thickness, an increase in inner layer porosity, as well as formation of a wide calcium-containing region within a coating outer layer. Calcium contributes to a significant change in coating phase composition (α-Al2O3/g-Al2O3), preventing a-Al2O3 formation. A change in phase composition leads to a reduction in coating average microhardness from 912 HV on pure aluminum to 714 HV for a coating upon Al–Ca alloy. The electrochemical behavior of as-cast Al7Ca alloy and PEO-treated alloys in 3.5% NaCl solution is studied. As a result of electrochemical studies, it is found that a PEO coating significantly increases corrosion resistance, demonstrating a decrease in corrosion current density (0.410–3 mA/cm2) compared with an uncoated specimen (7.1× 10–3 mA/cm2). A coating formed upon pure aluminum due to greater uniformity shows a lower corrosion current density value (0.0710–3 mA/cm2) and improved corrosion properties.

Similar content being viewed by others

References

A. G. Rakoch, A. A. Gladkova, and A. V. Dub, Plasma-Electrolytic Treatment of Aluminum and Titanium Alloys [in Russian], ID MISiS, Moscow (2017).

L. Zhu, Z. Guo, Y. Zhang, Z. Li, and M. Sui, “A mechanism for the growth of a plasma electrolytic oxide coating on Al,” Electrochim. Acta., 208, 296–303 (2016); DOI: https://doi.org/10.1016/j.electacta.2016.04.186.

N. Yu. Dudareva, A. B. Kruglov, and R. Gallyamova, “Structure and thermophysical properties of coatings formed by the method of microarc oxidation on an aluminum alloy AK4–1,” Solid State Phenom., 284, 1235–1241 (2018); DOI: https://doi.org/10.4028/www.scientific.net/SSP.284.1235.

X. Huang and L. Famiyeh, “Plasma electrolytic oxidation coatings on aluminum alloys: microstructures, properties, and applications,” Modern Concepts in Mater. Sci., 2, 1–13 (2019); DOI: https://doi.org/10.33552/MCMS.2019.02.000526.

Y.-J. Oh, J.-I. Mun, and J.-H. Kim, “Effects of alloying elements on microstructure and protective properties of Al2O3 coatings formed on aluminum alloy substrates by plasma electrolysis,” Surface & Coatings Technology, 204, 141–148 (2009); DOI:https://doi.org/10.1016/j.surfcoat.2009.07.002.

T. Wu, C. Blawerta, and M. L. Zheludkevich, “Influence of secondary phases of AlSi9Cu3 alloy on the plasma electrolytic oxidation coating formation process,” J. Mater. Sci. Technol., 50, 75–85 (2020); DOI: https://doi.org/10.1016/j.jmst.2019.12.031.

A. E. Gulec, Y. Gencer, and M. Tarakci, “The characterization of oxide based ceramic coating synthesized on Al–Si binary alloys by microarc oxidation,” Surf. Coating. Technol., 269, 100–107 (2015); DOI: https://doi.org/10.1016/j.surfcoat.2014.12.031.

K. Li, W. Li, G. Zhang, W. Zhu, F. Zheng, D. Zhang, and M. Wang, “Effects of Si phase refinement on the plasma electrolytic oxidation of eutectic Al–Si alloy,” J. Alloys. Compd., 790, 650–656 (2019); DOI: https://doi.org/10.1016/j.jallcom.2019.03.217.

A. B. Rogov, H. Lyu, A. Matthews, and A. Yerokhin, “AC plasma electrolytic oxidation of additively manufactured and cast AlSi12 alloys,” Surf. Coat. Technol., 399, 126116 (2020); DOI: https://doi.org/10.1016/j.surfcoat.2020.126116.

L. Pezzato, M. Dabala, S. Gross, and K. Brunelli, “Effect of microstructure and porosity of AlSi10Mg alloy produced by selective laser melting on the corrosion properties of plasma electrolytic oxidation coatings,” Surf. Coat. Technol., 404, 126477 (2020); DOI: https://doi.org/10.1016/j.surfcoat.2020.126477.

S. Cengiz, “Synthesis of eutectic Al–18Ce alloy and effect of cerium on the PEO coating growth,” Mater. Chem. Phys., 247, 122897 (2020); DOI: 0.1016/j.matchemphys.2020.122897.

K. A. Cosan, K. O. Gunduz, M. Tarakcı, and Y. Gencer, “Plasma electrolytic oxidation of as-cast and heat-treated binary Al–Ni alloys,” Surf. Coat. Technol., 450. 128998 (2020); DOI: https://doi.org/10.1016/j.surfcoat.2022.128998.

N. A. Belov, E. A. Naumova, and T. K. Akopyan, Eutectic Alloys Based Upon Aluminum: New Alloy Systems [in Russian], Ruda i Metally, Moscow (2016).

T. K. Akopyan, N. V. Letyagin and N. N. Avxentieva, “Hightech alloys based on Al–Ca–La(–Mn) eutectic system for casting, metal forming and selective laser melting,” Non-Ferrous Metals, No. 1, 52–59 (2020); DOI: https://doi.org/10.17580/nfm.2020.01.09.

T. K. Akopyan, N. V. Letyagin, T. A. Sviridova, N. O. Korotkova, and A. S. Prosviryakov, “New casting alloys based on the Al+Al4(Ca,La) eutectic,” JOM, 72, 3779–3786 (2020); DOI: https://doi.org/10.1007/s11837–020–04340-z

N. V. Letyagin, A. F. Musin, and L. S. Sichev “New aluminum-calcium casting alloys based on secondary raw materials,” Materials Today: Proceedings, 38, 1551–1555 (2021); DOI: https://doi.org/10.1016/j.matpr.2020.08.148.

N. A. Belov, E. A. Naumova, V. D. Ilyukhin, and V. V. Doroshenko, “Structure and properties of Al – 6% Ca – 1% Fe alloy castings prepared by casing under pressure,” Tsvet. Met., No. 3, 69–75 (2017); DOI: https://doi.org/10.17580/tsm.2017.03.11.

V. V. Doroshenko, E. A. Naumova, M. A. Barykin, and A. N. Koshmin, “Study of technological properties of new aluminumcalcium alloys for pistons of internal combustion Engines,” Tsvetnye Metally, No. 1, 62–71 (2022); DOI: https://doi.org/10.17580/tsm.2022.01.08.

O. V. Volkova, A. V. Dub, A. G. Rakoch, A. A. Gladkova, and M. E. Samoshna, “Comparison of tendency towards pitting corrosion of castings of experimental alloys Al6Ca, Al1Fe, Al6Ca1Fe and industrial alloy AK12M2,” Izv. Vuzov. Tsvet. Met., No. 5, 75–81 (2017); DOI: https://doi.org/10.17073/0021-3438-2017-5-75-81.

C. Liu, Q. Wang, X/ Cao, L. Cha, R. Ye, and C. S. Ramachandran, “Significance of plasma electrolytic oxidation treatment on corrosion and sliding wear performances of selective laser melted AlSi10Mg alloy,” Mater Charact., 181, 111479 (2021); DOI: https://doi.org/10.1016/j.matchar.2021.111479.

K. Li, W. Li, G. Zhang, and P. Guo, “Preparation of black PEO layers on Al–Si alloy and the colorizing analysis,” Vacuum, 111, 131–136 (2015); DOI: https://doi.org/10.1016/j.vacuum.2014.10.008.

L. Pezzato, M. Rigon, A. Martucci, K. Brunelli, and M. Dabala, “Plasma Electrolytic Oxidation (PEO) as pretreatment for sol-gel coating on aluminum and magnesium alloys,” Surf. Coat. Technol., 366, 114–123 (2019); DOI: https://doi.org/10.1016/j.surfcoat.2019.03.023.

N. Yu. Dudareva, A. V. Kolomeichenko, V. B. Deev, and V. M. Sitdikov, “Porosity of oxide ceramic coatings formed by micro-arc oxidation on high-silicon aluminum alloys,” J. Surface Investigation: X-ray, Synchrotron and Neutron Techniques, 16, 1308–1314 (2022); DOI: https://doi.org/10.1134/S1027451022060362.

P. Jantimapornkij, J. Zerrer, and A. Buling, “Advanced corrosion protection of additive manufactured light metals by creating ceramic surface through CERANOD plasma electrolytical oxidation process,” Front. Chem. Sci. Eng., 3, 734644 (2021); DOI: https://doi.org/10.3389/fceng.2021.734644.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 10, pp. 43–49, October, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Letyagin, N.V., Akopyan, T.К., Sokorev, A.A. et al. Structure and Properties of Coatings Formed on Cast Al–Ca Alloys by Plasma Electrolytic Oxidation. Metallurgist 67, 1473–1481 (2024). https://doi.org/10.1007/s11015-024-01640-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01640-6