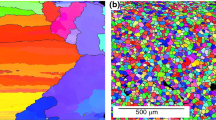

Introduction of 0.3% Cr into Al–Cu–Er–Zr alloy leads to significant modification of the grain structure and almost complete elimination of a dendritic structure. The average grain size of 40 μm corresponds to the size of a dendritic cell. The good modifying capacity is explained by formation of intermetallic compounds of the phase first identified of approximate composition Al75–80Cu10–12Er3–4Cr7, which is a substrate for nucleation of primary aluminum. After quenching and aging, slight hardening in the alloy is achieved due to L12 –Al3(Zr,Er) dispersoids with an average diameter of 40 nm and q’(Al2Cu) precipitates with a diameter up to 100 nm and a thickness up to 5 nm. No particles containing chromium are found within the matrix. According to thermodynamic calculations, hot rolling of AlCuErZrCr alloy at a temperature of 440°C should proceed in the ((Al)+Al3Zr+Al7Cr) phase region. However, analysis of the fine structure in an annealed condition after rolling showed presence of only L12 –Al3(Zr,Er) dispersoids. Differences in alloy hardness on annealing up to 300°C may be explained either by the influence of dissolved chromium atoms or by formation of chromium-containing particle clusters, which could not be detected.

Similar content being viewed by others

References

ASM International Handbook Committee ASM Handbook Vol. 2: Properties and Selection–Nonferrous Alloys and Special-Purpose Materials (2001); ISBN 0871700077.

V. S. Zolotorevsky, N. A. Belov, and M. V. Glazoff, Casting Aluminum Alloys (2007); ISBN 9780080453705.

D. G. Eskin, Suyitno, and L. Katgerman, “Mechanical properties in the semi–solid state and hot tearing of aluminium alloys,” Prog. Mater. Sci., 49, 629–711 (2004).

V. S. Zolotorevskii, A. V. Pozdnyakov, and A. Y. Churyumov, “Search for promising compositions for developing new multiphase casting alloys based on Al–Cu–Mg matrix using thermodynamic calculations and mathematic simulation,” Physics of Metals and Metallography, 113, 1052–1060 (2012).

A. V. Pozdniakov and V. S. Zolotorevskiy, “Determining hot cracking index of Al–Si–Cu–Mg casting alloys calculated using effective solidification range,” Intern. J. Cast Metals Research, 27, 193–198 (2014).

T. Krachan, B. Stel’makhovych, and Y. Kuz’ma, “The Y–Cu–Al system,” J. Alloys and Compounds, 349, 134–139 (2003).

L. Zhang, P. J. Masset, X. Tao, G. Huang, H. Luo, L. Liu, and Z. Jin, “Thermodynamic description of the Al–Cu–Y ternary system,” Calphad Comput. Coupling Phase Diagrams Thermochem., 35, 574–579.

L. G. Zhang, L. B. Liu, G. X. Huang, H. Y. Qi, B. R. Jia, and Z. P. Jin, “Thermodynamic assessment of the Al–Cu–Er system,” Calphad Comput. Coupling Phase Diagrams Thermochem., 32, 527–534 (2008).

L. Zhang, P. J. Masset, F. Cao, F. Meng, L. Liu, and Z. Jin, “Phase relationships in the Al–rich region of the Al–Cu–Er system,” J. Alloys Compd., 509, 3822–3831 (2011).

G. Huang, L. Liu, L. Zhang, and Z. Jin, “Thermodynamic description of the Al–Cu–Yb ternary system supported by first–principles calculations,” J. Mining and Metallurgy, Section B: Metallurgy, 52, 177–183 (2016).

N. A. Belov, A. V. Khvan, and A. N. Alabin, “Microstructure and phase composition of Al–Ce–Cu alloys in the Al–rich corner,” Proceedings of the Materials Science Forum, 519–521, 395–400 (2006).

N. A. Belov and A. V. Khvan, “The ternary Al–Ce–Cu phase diagram in the aluminum–rich corner,” Acta Materialia, 55, 5473–5482 (2007).

A. V. Pozdniakov and R. Y. Barkov, “Microstructure and materials characterisation of the novel Al–Cu–Y alloy,” Materials Science and Technology (United Kingdom), 34, 1489–1496 (2018).

A. V. Pozdnyakov, R. Y. Barkov, Z. Sarsenbaev, S. M. Amer, and A. S. Prosviryakov, “Evolution of microstructure and mechanical properties of a new Al–Cu–Er wrought alloy,” Physics of Metals and Metallography, 120, 614–619 (2010).

S. M. Amer, R. Y. Barkov, O. A. Yakovtseva, and A. V. Pozdniakov, “Comparative analysis of structure and properties of quasibinary Al–6.5Cu–2.3Y and Al–6Cu–4.05Er alloys,” Physics of Metals and Metallography, 121, 476–482 (2020).

S. M. Amer, R. Y. Barkov, and A. V. Pozdniakov, “Microstructure and mechanical properties of novel quasibinary Al–Cu–Yb and Al–Cu–Gd alloys,” Metals (Basel), 11, 1–11 (2021).

S. M. Amer, R. Yu. Barkov, O. A. Yakovtseva, I. S. Loginova, and A. V. Pozdniakov, “Effect of Zr on microstructure and mechanical properties of the Al–Cu–Er alloy,” Mater. Sci. and Technology, 36, 453–459 (2020).

A. V. Pozdnyakov, R. Y. Barkov, S. M. Amer, V. S. Levchenko, A. D. Kotov, and A. V. Mikhaylovskaya, “Microstructure, mechanical properties and superplasticity of the Al–Cu–Y–Zr alloy,” Materials Science and Engineering: A, 758, 28–35 (2019).

S. M. Amer, A. V. Mikhaylovskaya, R. Y. Barkov, A. D. Kotov, A. G. Mochugovskiy, O. A. Yakovtseva, M. V. Glavatskikh, I. S. Loginova, S. V. Medvedeva, and A. V. Pozdniakov, “Effect of homogenization treatment regime on microstructure, recrystallization behavior, mechanical properties, and superplasticity of Al–Cu–Er–Zr alloy,” JOM, 73, 3092–3101 (2021).

O. I. Mamzurina, S. M. Amer, I. S. Loginova, M. V. Glavatskikh, A. G. Mochugovskiy, R. Y. Barkov, and A. V. Pozdniakov, “Effect of Zr on microstructure and mechanical properties of the Al–Cu–Yb and Al–Cu–Gd alloys,” Metals (Basel), 12, 479 (2022).

S. M. Amer, R. Y. Barkov, A. S. Prosviryakov, and A. V. Pozdniakov, “Structure and properties of new heat-resistant cast alloys based on the Al–Cu–Y and Al–Cu–Er systems,” Physics of Metals and Metallography, 122, 908–914 (2021).

S. M. Amer, R. Y. Barkov, A. S. Prosviryakov, and A. V. Pozdniakov, “Structure and properties of new wrought Al–Cu–Y– and Al–Cu–Er–based alloys,” Physics of Metals and Metallography, 122, 915–922 (2021).

O. I. Mamzurina, S. M. Amer, M. V. Glavatskikh, R. Y. Barkov, I. S. Loginova, and A. V. Pozdniakov, “Microstructure and mechanical properties of novel heat resistant cast Al–Cu–Yb(Gd)–Mg–Mn–Zr alloys,” Metals (Basel), 12, 2079 (2022).

R. A. Karnesky, D. C. Dunand, and D. N. Seidman, “Evolution of nanoscale precipitates in Al microalloyed with Sc and Er,” Acta Materialia, 57(14), 4022–4031 (2009).

Y. Harada and D. Dunand, “Microstructure of Al3Sc with ternary transition–metal additions,” Materials Science and Engineering: A, 329–331, 686–695 (2002).

L. E. Gorlov, I. S. Loginova, M. V. Glavatskikh, R. Yu. Barkov, and A. V. Pozdniakov, “Novel precipitation strengthened Al–Y–Sc–Er alloy with high mechanical properties, ductility and electrical conductivity produced by different thermomechanical treatments,” J. Alloys Compd., 918, 165748 (2022).

S. P. Wen, K. Y. Gao, Y. Li, H. Huang, and Z. R. Nie, “Synergetic effect of Er and Zr on the precipitation hardening of Al–Er–Zr alloy,” Scripta Materialia, 65, No. 7, 592–595 (2011).

A. V. Pozdniakov, R. Y. Barkov, A. S. Prosviryakov, A. Y. Churyumov, I. S. Golovin, and V. S. Zolotorevskiy, “Effect of Zr on the microstructure, recrystallization behavior, mechanical properties and electrical conductivity of the novel Al–Er–Y alloy,” J. Alloys Compd., 765, 1–6 (2018).

H. Li, J. Bin, J. Liu, Z. Gao, and X. Lu, “Precipitation evolution and coarsening resistance at 400°C of Al microalloyed with Zr and Er,” Scripta Materialia, 67, No. 1, 73–76 (2012).

S. P. Wen, K. Y. Gao, H. Huang, W. Wang, and Z. R. Nie, “Precipitation evolution in Al–Er–Zr alloys during aging at elevated temperature,” J. Alloys Compd., 574, 92–97 (2013).

S. P. Wen, W. Wang, W. H. Zhao, X. L. Wu, K. Y. Gao, H. Huang, and Z. R. Nie, “Precipitation hardening and recrystallization behavior of Al–Mg–Er–Zr alloys,” J. Alloys Compd., 687, 143–151 (2016).

A. V. Pozdniakov, V. Yarasu, R. Yu. Barkov, O. A. Yakovtseva, S. V. Makhov, and V. I. Napalkov, “Microstructure and mechanical properties of novel Al–Mg–Mn–Zr–Sc–Er alloy,” Materials Letters, 202, 116–119 (2017).

M. Song, K. Du, Z. Y. Huang, H. Huang, Z. R. Nie, and H. Q. Ye, “Deformation–induced dissolution and growth of precipitates in an Al–Mg–Er alloy during high-cycle fatigue,” Acta Materialia, 81, 409–419 (2014).

Y. Wang, X. Wu, I. Cao, X. Tong, M. J. Couper, and Q. Liu, “Effect of trace Er on the microstructure and properties of Al–Zn–Mg–Cu–Zr alloys during heat treatments,” Mater. Sci. Engineering: A, 792, No. 5, 139807 (2020).

Y. Huang, C. Zhang, Y. Ma, and Y. Liu, “Effects of homogenization on the dissolution and precipitation behavior of intermetallic phase for a Zr and Er containing Al–Zn–Mg–Cu alloy,” Progress in Natural Science: Materials Intern., 30, No. 1, 47–53 (2020).

H. C. Fang, H. Chao, and K. H. Chen, “Effect of Zr, Er and Cr additions on microstructures and properties of Al–Zn–Mg–Cu alloys,” Materials Science and Engineering: A, 610, 10–16 (2014).

M. V. Glavatskikh, R. Y. Barkov, M. G. Khomutov, and A. V. Pozdniakov, “The effects of yttrium and erbium on the phase composition and aging of the Al–Zn–Mg–Cu–Zr alloy with a high copper content,” Physics of Metals and Metallography, 123, 617–623 (2022).

M. Colombo, E. Gariboldi, and A. Morri, “Er addition to Al–Si–Mg-based casting alloy: effects on microstructure, room and high temperature mechanical properties,” J. Alloys Compd., 708, 1234–1244 (2017).

R. Yu. Barkov, A. S. Prosviryakov, M. G. Khomutov, and A. V. Pozdniakov, “Effect of the Zr and Er content on the structure and properties of the Al–5Si–1.3Cu–0.5Mg alloy,” Physics of Metals and Metallography, 122, 614–620 (2021).

R. Yu. Barkov, A. G. Mochugovskiy, M. G. Khomutov, and A. V. Pozdniakov, “Effect of Zr and Er small additives on phase composition and mechanical properties of Al–5Si–1.3Cu–0.5Mg alloy,” Physics of Metals and Metallography, 122, No. 2, 161–168 (2021).

H. C. Fang, F. H. Luo, and K. H. Chen, “Effect of intermetallic phases and recrystallization on the corrosion and fracture behavior of an Al–Zn–Mg–Cu–Zr–Yb–Cr alloy,” Mater. Sci. and Engineering: A, 684, 480–490 (2017).

H. C. Fang, K. H. Chen, X. Chen, H. Chao, and G. S. Peng, “Effect of Cr, Yb and Zr additions on localized corrosion of Al–Zn–Mg–Cu alloy,” Corrosion Science, 51, 2872–2877 (2009).

G. Peng, K. Chen, H. Fang, and S. Chen, “Effect of Cr and Yb additions on microstructure and properties of low copper Al–Zn–Mg–Cu–Zr alloy,” Materials and. Design, 36, 279–283 (2012).

H. C. Fang, H. Chao, and K. H. Chen, “Effect of Zr, Er and Cr additions on microstructures and properties of Al–Zn–Mg–Cu alloys,” Materials Science and Engineering: A, 610, 10–16 (2014).

H. C. Fang, K. H. Chen, X. Chen, L. P. Huang, G. S. Peng, and B. Y. Huang, “Effect of Zr, Cr and Pr additions on microstructures and properties of ultra-high strength Al–Zn–Mg–Cu alloys,” Materials Science and Engineering: A, 528, 7606–7615 (2011).

Y. Meng, Z. Zhao, and J. Cui, “Effect of minor Zr and Sc on microstructures and mechanical properties of Al–Mg–Si–Cu–Cr–V alloys,” Transactions of Nonferrous Metals Society of China, 23, 1882–1889 (2013).

Y. I. Kosov and V. Y. Bazhin, “Synthesis of an aluminum–erbium master alloy from chloride–fluoride melts,” Russian Metallurgy (Metally), 2018, No. 2, 139–148 (2018).

S. Savchenkov, Y. Kosov, V. Bazhin, K. Krylov, and R. Kawalla, “Microstructural master alloys features of aluminum–erbium system,” Crystals, 11, No. 11, 1353 (2021).

Y. I. Kosov and V. Y. Bazhin, “Features of phase formation during aluminothermal preparation of aluminum–erbium master alloy,” Metallurgist, 62, No. 5-6, 440–448 (2018).

Y. I. Kosov, V. Y. Bazhin, and V. G. Povarov, “Interaction of erbium fluoride with alkali metal chloride–fluoride melts in synthesizing an Al–Er master alloy,” Russian Metallurgy (Metally), No. 6, 539–544 (2018).

Y. I. Kosov and V. Y. Bazhin, “Preparation of novel Al–Er master alloys in chloride–fluoride melt,” Materials Science Forum, 918, 21–27 (2018).

S. M. Amer, O. A. Yakovtseva, I. S. Loginova, S. V. Medvedeva, A. S. Prosviryakov, A. I. Bazlov, R. Y. Barkov, and A. V. Pozdniakov, “The phase composition and mechanical properties of the novel precipitation–strengthening Al–Cu–Er–Mn–Zr alloy,” Applied Sciences–Basel, 10(15), 5345 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 67, No. 10, pp. 28–33, October, 2023. Russian https://doi.org/10.52351/00260827_2023_10_28

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Amer, S.M., Glavatskikh, M.V., Barkov, R.Y. et al. Effect of Chromium on Microstructure and Mechanical Properties of Al–Cu–Er–Zr Alloy. Metallurgist 67, 1448–1456 (2024). https://doi.org/10.1007/s11015-024-01637-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-024-01637-1