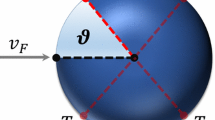

Rotary furnaces are used as reactors to intensify chemical processes between the powder and gas atmosphere around it. The furnace rotation leads to relative motion and dilation of the powder layers, facilitating gas access. The paper is devoted to the modeling of nickel oxide powder behavior in a rotary furnace to estimate the contribution of furnace rotation speed to gas permeability when the nickel oxide granules are reduced in a hydrogen atmosphere. Discrete element modeling of powder granules in a rotary furnace was conducted employing Altair EDEM commercial software to estimate the powder gas permeability at different stages. The powder bed in a horizontal cylindrical rotary furnace was modeled as a packing of identical spherical granules with diameters equal to those of the nickel oxide granules. The furnace rotation led to periodic oscillations of the powder along the furnace wall with an amplitude that gradually diminished to some steady value. Gas permeability of the powder bed was evaluated through the porosity function, derived from the Carman permeability equations. Greater gas permeability resulting from significant powder dilation was observed only in active shear zones on the powder bed surface and in the contact area between the powder and the furnace wall. Sizes of the shear zones depended on the furnace rotation speed but never exceeded several granule diameters for all rotation speeds. The efficiency of a rotary furnace as a chemical reactor was shown to be determined not only by the powder dilation but also by the regeneration rate for the powder bed surface. The regeneration rate can be calculated and changes nonlinearly with the furnace rotation speed.

Similar content being viewed by others

References

P.Ya. Radchenko, V.V. Panichkina, and O.G. Radchenko, “Properties of molybdenum powder obtained by reduction in moving beds,” Powder Metal. Met. Ceram., 38, No. 9–10, 429–435 (1999).

S.L. Rovin, A.S. Kalinichenko, and L.E. Rovin, “Recycling of dispersed metal wastes in rotary furnaces,” J. Casting Mater. Eng., 3(2), 43–49 (2019).

O.A. Katrus, R.L. Oganyan, and V.N. Artem’ev, “Gas permeability of metal powders,” Powder Metall. Met. Ceram., 9, No. 10, 783–785 (1970).

A. Burgisser, “A semi-empirical method to calculate the permeability of homogeneously fluidized pyroclastic material,” J. Volcanol. Geotherm. Res., 243–244, 97–106 (2012).

EDEM Features—Discrete Element Modeling—DEM Software, https://altair.com/edem/features.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 62, Nos. 7–8 (552), pp. 3–10, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Maximenko, A.L., Hetman, O.I., Shtern, M.B. et al. Modeling the Gas Permeability of the Powder Bed in a Rotary Furnace. Powder Metall Met Ceram 62, 383–389 (2023). https://doi.org/10.1007/s11106-024-00401-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-024-00401-z