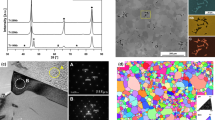

Features peculiar to the synthesis of SiC–Si3N4–Si2N2O composite powder with a controlled content of silicon carbide, nitride, and oxynitride phases, as well as the structure and properties of hot-pressed ceramics produced from this powder, were examined. The optimal composition of the synthesized SiC–Si3N4–Si2N2O powder was achieved by heating a 1 : 3 mixture of thermally expanded graphite (TEG) and silicon up to 1200°C in air. The interaction of TEG with fine silicon at 1200°C led to the formation of a solid solution of carbon in silicon carbide, accompanied by heat release. The generated heat increased temperature within localized volumes of the TEG cellular structure to a level where air nitrogen facilitated the development of silicon nitride and oxynitride and an amorphous phase. The amorphous phase crystallized as the interaction time increased to 2.5 h. The duration of the process influenced the final distribution of the phases, formed with the participation of CO, SiO, and air nitrogen. The microstructure of the synthesized powder was characterized by a general agglomerated state, resulting from rod and plate forms of Si3N4 and Si2N2O. Hot pressing of the synthesized SiC–Si3N4–Si2N2O composite powder with Al2O3 and Y2O3 activators yielded superfine ceramics, possessing enhanced hardness and fracture toughness (HV10 = 20.7 GPa and KIc = 6.5 MPa · m1/2). The structure of the ceramics sintered at 2000°C differed from those sintered at 1850°C, primarily by higher density and average grain size. The superfine state significantly influenced the abrasive wear resistance of the ceramics in dry friction conditions. The linear wear index of a sample with an average size of structural elements varying from 0.2 to 1.5 μm was 111 μm/km at a sliding speed of 1 m/sec under a load of 0.2 MPa. This was significantly lower than the linear wear index of industrial ceramics of reaction-sintered silicon carbide (RSSC), which was 232.4 μm/km.

Similar content being viewed by others

References

B.K. Padhi and C. Patnaik, “Development of Si2N2O, Si3N4 and SiC ceramic materials using rice husk,” Ceram. Int., 21, No. 3, 213–220 (1995).

Z. Lenea, A. Bellosib, and F. Monteverdeb, “Factors influencing the crystallization and densification of ultrafine Si/N/C,” Chem. Phys. Mater., 41, No. 1, 46–54 (1995).

A.P. Amosov, G.S. Belova, Yu.V. Titova, and D.A. Maidan, “Synthesis of superfine powder ceramic Si3N4–SiC composite through combustion of the components in the Si–C–NaN3–NH4F system,” Zh. Neorg. Khim., 67, No. 2, 1–9 (2022).

M. Purteman, P. Decamp, F. Cambie, M. Plisnier, V. Canonne, and J.K. Decamp, “Silicon nitride/silicon carbide nanocomposite obtained by SiC nitriding: fabrication and high-temperature mechanical properties,” J. Eur. Ceram. Soc., 23, No. 13, 2361–2366 (2003).

M.F. Zawrah, M.A. Zayed, and Moustafa R.K. Ali, “Synthesis and characterization of SiC and SiC/Si3N4 composite nano powders from waste material,” J. Hazard. Mater., 227–228, 250–256 (2012).

R. Mach, D. Klotzh, and J. Koche, “Syntheses of nanosized Si3N4–SiC composite powder by RF–plasma,” Silicatind., 60, No. 11–12, 299–303 (1995).

O. Mykhaylyk and M. Gadzira, “Arrangement of C atoms in the SiC–C solid solution,” Acta Cryst., B55, 297–305 (1999).

N.F. Gadzyra, G.G. Gnesin, and A.A. Mykhailyk, “Mechanism for the formation of a solid solution of carbon in silicon carbide,” Powder Metall. Met. Ceram., 40, No. 9–10, 519–525 (2001).

N.F. Gadzyra, G.G. Gnesin, and A.A. Mykhailyk, “Nanocomposite ceramics based on powder of the solid solution of carbon in silicon carbide,” Ogneup. Tekh. Keram., No. 12, 4–9 (2001).

I.G. Chernysh, I.I. Karpov, G.P. Prikhodko, and V.M. Shay, Physicochemical Properties of Graphite and Its Compounds [in Russian], Naukova Dumka, Kyiv (1990), p. 200.

S.J. Gregg and K.S.W. Sing, Adsorption, Surface Area and Porosity, Academic Press, London–New York (1967).

N.K. Davidchuk, N.F. Gadzyra, and G.G. Gnesin, “Some characteristic features of formation of ceramics based on composite powders SiC–Si3N4–Si2N2O,” Powder Metall. Met. Ceram., 40, No. 1–2, 49–53 (2001).

L.V. Gurvich, G.A. Bergman, I.V. Veits, V.A. Medvedev, G.A. Khachkuruzov, and V.S. Yugman, Thermodynamic Properties of Individual Substances: Reference Edition [in Russian], in 4 Vols., Nauka, Moscow (1979), Vol. II, Book 1, p. 438.

E.I. Sadkovskii, I.Ya. Guzman, and V.F. Kutukov, “On the chemistry in reaction sintering of silicon carborundum compositions in a CO and N2 atmosphere,” Neorg. Mater., IV, No. 7, 1186–1188 (1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 62, Nos. 7–8 (552), pp. 98–109, 2023.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Davydchuk, N.K., Gadzyra, M.P., Tymoshenko, Y.G. et al. Synthesis and Consolidation of Composite Materials in the SiC–Si3N4–Si2N2O System. Powder Metall Met Ceram 62, 459–468 (2023). https://doi.org/10.1007/s11106-024-00407-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-024-00407-7