Abstract

Aiming at the problem of lower single granularity and uniformity of the existing air-suction seed-metering device under the condition of densely planted crops according to the agronomic requirements of soybean-maize strip intercropping mode, the disturbing effect of seeds on the seed-filling performance was studied to improve the seeding performance of the seed-metering device under the condition of high speed. Based on the theory of discrete element method (DEM), taking the air-suction seed-metering device designed for both soybean and maize as a model and maize variety of ‘Zhengdan 958’ suitable for densely planted as the research object, the DEM single-factor test was conducted on the influence of the structure, position, and number of bosses on disturbing performance with the average kinetic energy, average velocity, and average normal force of seeds as evaluation indexes. The results showed that the disturbing performance of seeds was better when the boss structure was D-type, the diameter of the base circle where bosses located was 160 mm, and the number of bosses was 13. To further improve the structural parameters of the D-type boss, the primary structural parameters, such as the side length and arc radius, were simulated by a single-factor test. The position, side length, and arc radius of the D-type boss were further optimized and verified using central composite design (CCD) based on the results of the single-factor test. The CCD results showed that the average kinetic energy of seeds was 7.39 × 10−7 J, the average velocity was 4.53 × 10−2 m/s, and the average normal force was 6.18 × 10−2 N when the diameter of the base circle where bosses located at 159.865 mm, the side length and arc radius of the D-type boss of 5.690 mm and 5.476 mm, which significantly enhanced the disturbing performance of the seed-metering device. The optimized boss structures and parameters of the seed-metering device were validated with an all-factor test of working speed and working pressure. When the working speed and working pressure were 4 ~ 6 km/h and 7 ~ 7.5 kPa, the qualified rate was 94.75% ~ 97.49%, the multiple rate was 0.92% ~ 1.43%, and the leakage rate was 1.59% ~ 3.82%, all of which were substantially lower than the original one. Therefore, the seed-filling performance of the seed-metering device will be improved by increasing the disturbance of seeds to a certain extent.

Similar content being viewed by others

References

Yang WY, Yang F (2019) Developing maize-soybean strip intercropping for demand security of national food. Sci Agric Sin 52(21):3748–3750

Xin L, Tanzeelur R, Song C, Su BY, Yang F, Yong TW, Wu YS, Zhang CY, Yang WY (2017) Changes in light environment, morphology, growth and yield of soybean in maize-soybean intercropping systems. Field Crop Res 200:38–46

Yang H, Zhou Y, Chen P, Du Q, Zheng BC, Pu T, Wen J, Yang WY, Yong TW (2022) Effects of nutrient uptake and utilization on yield of maize-legume strip intercropping system. Acta Agron Sin 48(6):1476–1487

Liu DL, Chen SW, Liu XC, Yang F, Liu WG, She YH, Du JB, Liu CY, Yang WY, Wu XL (2019) Genetic map construction and QTL analysis of leaf-related traits in soybean under monoculture and relay intercropping. Sci Rep 9:2716

Yang F, Wang XC, Liao DP, Lu FZ, Gao RC, Liu WG, Yong TW, Wu XL, Du JB, Liu J, Yang WY (2015) Yield response to different planting geometries in maize soybean relay strip intercropping systems. Agron J 107(1):296–304

Wang JW, Qi X, Xu CS, Wang ZM, Jiang YM, Tang H (2021) Design evaluation and performance analysis of the inside-filling air-assisted high-speed precision maize seed-metering device. Sustainability 13:5483

Xu J, Hou JW, Wu WB, Han CY, Wang XM, Tang T, Sun SL (2022) Key structure design and experiment of air-suction vegetable seed-metering device. Agronomy 12(3):675

Li JH, Lai QH, Zhang H, Zhang ZG, Zhao JW, Wang TT (2021) Suction force on high-sphericity seeds in an air-suction seed-metering device. Biosyst Eng 211:125–140

Yang L, Yan BX, Zhang DX, Zhang TL, Wang YX, Cui T (2016) Research progress of corn precision seeding technology. Trans Chin Soc Agric Mach 47(11):38–48

Lü JQ, Yang Y, Li ZH, Shang QQ, Li JC, Liu ZY (2016) Design and experiment of an air-suction potato seed metering device. Int J Agric & Biol Eng 9(5):33–42

Liu R, Liu ZJ, Zhao JL, Lu Q, Liu LJ, Li YH (2022) Optimization and experiment of a disturbance-assisted seed filling high-speed vacuum seed-metering device based on DEM-CFD. Agriculture 12(9):1304

Wang HY, Sun XP, Li H, Fu JY, Zeng XP, Xu YZ, Wang YJ, Liu HQ, Lü ZM (2022) Design and parameter optimization of a finger clip plate garlic seed-metering device based on EDEM. Agronomy 12(7):1543

Lai QH, Ma WP, Liu S, Su W, Zhang ZH (2017) Simulation and experiment on seed-filling performance of pneumatic disc seed-metering device for mini-tuber. Trans Chin Soc Agric Mach 48(5):44–53

Lai QH, Sun K, Yu QX, Qin W (2020) Design and experiment of a six-row air-blowing centralized precision seed-metering device for panax notoginseng. Int J Agric Biol Eng 13(2):111–122

Zhang K, Yi SJ (2017) Simulation and experimental optimization on filling seeds performance of seed metering device with roller of air-suction. Trans Chin Soc Agric Mach 48(7):78–86

Li SH, Liao QX, Wang D, Yao L, Lei XL, Wang L, Xing HC (2017) Simulation analyses and experiments of seed filling performance of pneumatic knurled cylinder-type centralized precision metering device for rapeseed. J Huazhong Agric Univ 36(5):99–107

Liao YT, Wang L, Liao QX (2017) Design and test of an inside-filling pneumatic precision centralized seed-metering device for rapeseed. Int J Agric Biol Eng 10(2):56–62

Shi S, Zhang DX, Yang L, Cui T, Li KH, Yin XW (2015) Simulation and verification of seed-filling performance of pneumatic-combined holes maize precision seed-metering device based on EDEM. Trans Chin Soc Agric Eng 31(3):62–69

Hu JP, Zhou CJ, Hou C, Wang J (2014) Simulation analysis of seed-filling performance of magnetic plate seed-metering device by discrete element method. Trans Chin Soc Agric Mach 45(2):94–98

Shi S, Liu H, Wei GJ, Zhou JL, Jian SC, Zhang RF (2020) Optimization and experiment of pneumatic seed metering device with guided assistant filling based on EDEM-CFD. Trans Chin Soc Agric Mach 51(5):54–66

Liu R, Liu ZJ, Liu LJ, Li YH (2022) Design and experiment of corn high speed air suction seed metering device with disturbance assisted seed-filling. Trans Chin Soc Agric Mach 53(9):50–59

Liu HX, Xu XM, Guo LF, Shang JJ (2014) Research on seed-filling mechanism of vertical shallow basin type seed-metering device with composite filling force. Trans Chin Soc Agric Eng 30(21):9–16

Liu HX, Liu JX, Tang SF, Xu XM (2016) Design on opposed inclined-plate high-speed precision seed-metering device and its working mechanism analysis. Trans Chin Soc Agric Eng 32(20):24–31

Wang MM, Liu QT, Ou YG, Zou XP (2021) Experimental study of the seed-filling uniformity of sugarcane single-bud billet planter. Sugar Tech 23(4):827–837

Wang MM, Liu QT, Ou YG, Zou XP (2022) Numerical simulation and verification of seed-filling performance of single-bud billet sugarcane seed-metering device based on EDEM. Agriculture 12:983–994

Liu CL, Wang YL, Du X, Song JN, Wang JC, Zhang FY (2019) Filling performance analysis and verification of cell-belt rice precision seed-metering based on friction and repeated filling principle. Trans Chin Soc Agric Eng 35(4):29–36

Yang W, Li JD, Gu LL, Zhang LL, Wang AH, Du WW (2019) Improvement and experiment of filling performance of maize breeding metering device based on EDEM software. Agric Eng 9(6):10–15

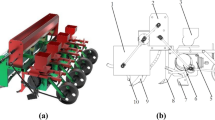

Han DD, He B, Yang WY, Xu Y, Lv XR, Zhang LH (2023) Design and experiment of an integrated air-suction soybean-corn strip intercropping planter. J Gansu Agric Univ 58(4):260–268

Ding L, Yang L, Liu SR, Yan BX, He XT, Zhang DX (2018) Design of air suction high speed precision maize seed metering device with assistant seed filling plate. Trans Chin Soc Agric Eng 34(22):1–11

Chen MZ, Diao PS, Zhang YP, Gao QM, Yang Z, Yao WY (2018) Design of pneumatic seed-metering device with single seed-metering plate for double-row in soybean narrow-row-dense-planting seeder. Trans Chin Soc Agric Eng 34(21):8–16

Chen FB, Gao J, Li WB, Fang P (2022) Transcriptome profiles reveal the protective role of seed coating with zinc against boron toxicity in maize (Zea mays L.). J Hazard Mater 423:127105

Li SL, Tan TT, Fan YF, Yang WY, Yang F (2019) Effects of maize shading on photosynthetic characteristics, vein and stomatal characteristics of soybean. Sci Agric Sin 52(21):3782–3793

Di RA, Di MFP (2004) Comparison of contact-force models for the simulation of collisions in DEM-based granular flow codes. Chem Eng Sci 59:525–541

Han DD, Zhang DX, Jing HR, Yang L, Cui T, Ding YQ, Wang ZD, Wang YX, Zhang TL (2018) DEM-CFD coupling simulation and optimization of an inside-filling air blowing maize precision seed-metering device. Comput Electron Agric 150:426–438

Shi L, Yang X, Zhao W, Sun W, Wang G, Sun B (2021) Investigation of interaction effect between static and rolling friction of corn kernels on repose formation by DEM. Int J Agric Biol Eng 14:238–246

Liu T, He RY, Lu J, Zou Y, Zhao MM (2016) Simulation and verification on seeding performance of nest hole wheel seed-metering device based on EDEM. J South China Agric Univ 37(3):126–132

Han DD, He B, Zhou Y, Yang WY, Xu Y, Zhang LH (2023) Design and experiment of air suction type dense planting precision seed metering device. J Huazhong Agric Univ 42(1):237–247

Acknowledgements

This work was supported by the Natural Science Foundation of Sichuan Province (2022NSFSC0138), the Technological Innovation R&D Projects of Chengdu Science and Technology Bureau (2022YF0501141SN), the National Modern Agricultural Industrial Technology System-Sichuan Beans and Multigrain Innovation Team (SCCXTD-2023-20) and the Listing Project of Rural Revitalization Research Institute of Sichuan Tianfu District (XZY1-11).

Funding

The funding was provided by Natural Science Foundation of Sichuan Province,2022NSFSC0138, Science and Technology Innovation Plan Of Shanghai Science and Technology Commission,2022YF0501141SN, National Modern Agricultural Industrial Technology System-Sichuan Beans and Multigrain Innovation Team, SCCXTD-2023-20, Xiao-Rong Lv, Listing Project of Rural Revitalization Research Institute of Sichuan Tianfu District, XZY1-11

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Han, DD., He, B., Wang, Q. et al. Optimization and experiment of seed-filling performance of the air-suction densely planted seed-metering device based on DEM. Comp. Part. Mech. (2024). https://doi.org/10.1007/s40571-024-00734-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40571-024-00734-x