Abstract

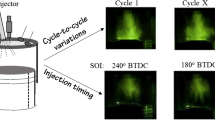

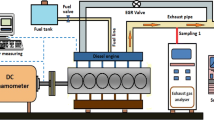

The objective of this study was to analyze through spray and engine experiments the effects of replacing mechanical injectors. The spray characteristics of the mechanical injectors of a used diesel engine and those of new mechanical injectors of the same model were compared. The injection quantity of the new injector was approximately 2–4% higher than that of the used injector owing to the deposit on the nozzle surface. The opening pressure of the used injector was 225 bar on account of the deterioration of the spring inside the injector. This pressure was lower than that of the new injector. The average spray penetration length of both injectors increased similarly up to 2 ms after injection. Owing to deposits on the nozzle surface, the spray angle of the used injectors tended to be smaller than those of the new injectors. The results of engine experiments showed that the new injectors recovered over 90% of engine torque and engine power on account of the increased fuel injection quantity. However, employing the new injectors caused heat loss and fuel consumption rate deterioration. The new injectors effectively reduced NOx and PM emissions by retarding the fuel injection timing and increasing the fuel injection pressure.

Similar content being viewed by others

Data availability

The datasets used and/or analysed during the current study available from the corresponding author on reasonable request.

Abbreviations

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- DPF:

-

Diesel particulate filter

- ECU:

-

Engine control unit

- EGR:

-

Exhaust gas recirculation

- EPA:

-

Environmental protection agency

- EU:

-

European Union

- HC:

-

Hydrocarbon

- NOx:

-

Nitrogen oxides

- O2 :

-

Oxygen

- P amb :

-

Ambient pressure

- PM:

-

Particulate matter

- RPM:

-

Revolutions per minute

- SCR:

-

Selective catalyst reduction

- SI:

-

Spark ignition

- TASOI:

-

Time after start of injection

- THC:

-

Total hydrocarbon

- US:

-

United States

References

Amaya, J., Zwolinski, P., & Brissaud, D. (2010). Environmental benefits of parts remanufacturing: The truck injector case. In 17th CIRP international conference on life cycle engineering, 2010. N/A.

Amiridis, M. D., Zhang, T., & Farrauto, R. J. (1996). Selective catalytic reduction of nitric oxide by hydrocarbons. Applied Catalysis B: Environmental, 10, 203–227.

Arrègle, J., Pastor, J. V., & Ruiz, S. (1999). The influence of injection parameters on diesel spray characteristics. SAE Technical Paper.

Badami, M., Mallamo, F., Millo, F., & Rossi, E. (2003). Experimental investigation on the effect of multiple injection strategies on emissions, noise and brake specific fuel consumption of an automotive direct injection common-rail diesel engine. International Journal of Engine Research, 4, 299–314.

Benajes, J., Molina, S., & García, J. M. (2001). Influence of pre-and post-injection on the performance and pollutant emissions in a HD diesel engine. SAE Transactions, 110, 361–371.

Chen, S. K. (2000). Simultaneous reduction of NOx and particulate emissions by using multiple injections in a small diesel engine. SAE Transactions, 2127–2136.

Choi, M., & Park, S. (2022). Optimization of multiple-stage fuel injection and optical analysis of the combustion process in a heavy-duty diesel engine. Fuel Processing Technology, 228, 107137.

D’Ambrosio, S., & Ferrari, A. (2012). Diesel injector coking: Optical-chemical analysis of deposits and influence on injected flow-rate, fuel spray and engine performance. Journal of Engineering for Gas Turbines and Power, 134.

Dhinesh, B., Lalvani, J. I. J., Parthasarathy, M., & Annamalai, K. (2016). An assessment on performance, emission and combustion characteristics of single cylinder diesel engine powered by Cymbopogon flexuosus biofuel. Energy Conversion and Management, 117, 466–474.

Farhan, S. M., Pan, W., Yan, W., Jing, Y., & Lili, L. (2020). Impact of post-injection strategies on combustion and unregulated emissions during different loads in an HSDI diesel engine. Fuel, 267, 117256.

Hardy, W. L., & Reitz, R. D. (2006). An experimental investigation of partially premixed combustion strategies using multiple injections in a heavy-duty diesel engine. SAE Transactions, 115, 514–531.

Hauser, R., Eisen, E. A., Pothier, L., & Christiani, D. C. (2001). A prospective study of lung function among boilermaker construction workers exposed to combustion particulates. American Journal of Industrial Medicine, 39, 454–462.

Hiroyasu, H., & Arai, M. (1990). Structures of fuel sprays in diesel engines. SAE Transactions, 99, 1050–1061.

Hotta, Y., Inayoshi, M., Nakakita, K., Fujiwara, K., & Sakata, I. (2005). Achieving lower exhaust emissions and better performance in an HSDI diesel engine with multiple injection. SAE Technical Paper, 1, 0928.

Imtenan, S., Varman, M., Masjuki, H., Kalam, M., Sajjad, H., Arbab, M., & Fattah, I. R. (2014). Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Conversion and Management, 80, 329–356.

Kang, W., Choi, B., Jung, S., & Park, S. (2018). PM and NOx reduction characteristics of LNT/DPF + SCR/DPF hybrid system. Energy, 143, 439–447.

Kidoguchi, Y., Nada, Y., Sangawa, S., Kitazaki, M., & Matsunaga, D. (2018). Effect of low load combustion and emissions on fuel dilution in lubricating oil and deposit formation of DI diesel engines fueled by straight rapeseed oil. Fuel, 221, 35–43.

Kimura, S., Aoki, O., Kitahara, Y., & Aiyoshizawa, E. (2001). Ultra-clean combustion technology combining a low-temperature and premixed combustion concept for meeting future emission standards. SAE Transactions, 110, 239–246.

Mccormick, R. L., Graboski, M. S., Alleman, T. L., Alvarez, J. R., & Duleep, K. (2003). Quantifying the emission benefits of opacity testing and repair of heavy-duty diesel vehicles. Environmental Science & Technology, 37, 630–637.

Payri, R., Salvador, F. J., Gimeno, J., & Montiel, T. (2020). Aging of a multi-hole diesel injector and its effect on the rate of injection. SAE Technical Papers, 01-0829.

Reşitoğlu, İA., Altinişik, K., & Keskin, A. (2015). The pollutant emissions from diesel-engine vehicles and exhaust aftertreatment systems. Clean Technologies and Environmental Policy, 17, 15–27.

Richards, P., Walker, R., & Williams, D. (1997). Fouling of two stage injectors-an investigation into some causes and effects. SAE Technical Paper.

Sullivan, J., Baker, R., Boyer, B., Hammerle, R., Kenney, T., Muniz, L., & Wallington, T. (2004). CO2 emission benefit of diesel (versus gasoline) powered vehicles. ACS Publications.

Tanaka, T., Ando, A., & Ishizaka, K. (2002). Study on pilot injection of DI diesel engine using common-rail injection system. JSAE Review, 23, 297–302.

Taşkiran, Ö. O., & Ergeneman, M. (2011). Experimental study on diesel spray characteristics and autoignition process. Journal of Combustion.

Twigg, B. M. V., & Phillips, P. R. (2009). Cleaning the air we breathe-controlling diesel particulate emissions from passenger cars. Platinum Metals Review, 53, 27–34.

Zhu, X., & Andersson, Ö. (2020). Performance of new and aged injectors with and without fuel additives in a light duty diesel engine. Transportation Engineering, 1, 100007.

Acknowledgements

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korea government (MOTIE) (no. 20224000000440, Sector coupling energy industry advancement manpower training program).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest, financial or otherwise.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jeong, M., Choi, M., Kim, N. et al. Effects of Mechanical Injector Replacement on Spray and Combustion Characteristics in an Agriculture Diesel Engine. Int.J Automot. Technol. (2024). https://doi.org/10.1007/s12239-024-00066-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12239-024-00066-y