Abstract

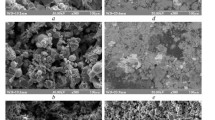

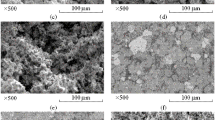

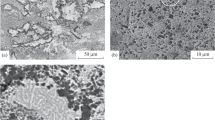

Ingots of a composite with a Fe−Cr–Mn–Mo–N–C matrix and reinforcing particles in the form of MgO, Al2O3, and AlN conglomerates have been produced by aluminothermy, which is a version of self-propagating high-temperature synthesis (SHS). The ingots differed mainly in carbon content. It has been found that with an increase in carbon content in the composite from 0.01 to 0.50 wt %, its hardness rises from 238 to 271 HV and its wear resistance improves. The wear resistance has been estimated by abrasive testing under the conditions of dry friction between the sample and a fixed abrasive−electrocorundum Р400 grit (28–40 μm) and Р80 grit (200–250 μm) abrasive paper. As a measure of wear resistance, we chose a decrease in sample weight after tests. The pressure with which the test material acted on the abrasive was roughly equal to 0.25 N/mm2, and the test time was 90 s. The loss in weight was been measured using VLR-200 balance. The hardness has been measured by Vickers hardness testing using an ITV-1-A hardness meter according to State Standard 2999-75 with a holding time of 10 s under a load of 30 kgf. It has been found that a rise in carbon content in the composite causes its embrittlement. It is noteworthy that in passing compressive strength tests samples with 0.01 and 0.16 wt % C remained intact, whereas those with 0.50 wt % C cracked. However, cracked samples continued deforming without complete breakdown up to a load that is maximum permissible for the test machine. The compressive strength has been estimated from the cracking load and has been found to be 3210 MPa. The ultimate compressive strength has been determined using an REM-100-A-2 multipurpose testing machine.

Similar content being viewed by others

REFERENCES

A. G. Svyazhin and L. M. Kaputkina, Izv. Vyssh. Uchebn. Zaved., Chern. Metall. 62 (3), 173 (2019). https://doi.org/10.17073/0368-0797-2019-3-173-187

M. V. Kostina and L. G. Rigina, Izv. Vyssh. Uchebn. Zaved., Chern. Metall. 63 (3), 606 (2020). https://doi.org/10.17073/0368-0797-2020-8-606-622

A. N. Maznichevskii, Yu. N. Goikhenberg, and R. V. Sprikut, Vestn. Yuzhno-Ural’sk. Gos. Univ. Ser. Metall. 20 (3), 42 (2020). https://doi.org/10.14529/met200305

M. O. Speidel, Materialwiss. Werkstofftech. 37 (10), 875 (2006). https://doi.org/10.1002/mawe.200600068

M. O. Speidel, Met. Sci. Heat Treat. 47 (11–12), 489 (2005). https://doi.org/10.1007/s11041-006-0017-y

E. A. Merkushin and V. V. Berezovskaya, Vestn. Tambovsk. Univ. Ser. Estestv. Tekh. Nauki 21 (3), 1160 (2016). https://doi.org/10.20310/1810-0198-2016-21-3-1160-1163

L. G. Korshunov, N. I. Noskova, A. V. Korznikov, N. L. Chernenko, and N. F. Vil’danova, Phys. Met. Metallogr. 108 (5), 519 (2009). https://doi.org/10.1134/S0031918X0911012X

V. V. Ilyushin and B. A. Potekhin, Lit’e Metall., No. 3S (57), 69 (2010). https://doi.org/10.21122/1683-6065-2010-3-69-72

I. E. Kalashnikov, L. K. Bolotova, L. I. Kobeleva, I. V. Ka- tin, P. A. Bykov, A. G. Kolmakov, R. S. Mikheev, and N. V. Kobernik, RF Patent No. 2585588 (2016).

G. Dorofeev, V. Karev, O. Goncharov, E. Kuzminykh, I. Sapegina, A. Lubnin, M. Mokrushina, and V. Lad’yanov, Metall. Mater. Trans. B 50 (2), 632 (2019). https://doi.org/10.1007/s11663-018-1499-x

V. I. Lad’yanov, G. A. Dorofeev, E. V. Kuz’minykh, V. A. Karev, and A. N. Lubnin, Izv. Vyssh. Uchebn. Zaved., Chern. Metall. 62 (2), 154 (2019). https://doi.org/10.17073/0368-0797-2019-2-154-162

G. A. Dorofeev, V. A. Karev, E. V. Kuzminykh, V. I. Lad’yanov, A. N. Lubnin, A. S. Vaulin, and M. I. Mokrushina, Russ. Metall. (Metally) 2013 (1), 1 (2013). https://doi.org/10.1134/S0036029513010047

A. Yu. Zuev and D. S. Tsvetkov, Chemical Thermodynamics: Textbook (Ural Univ., Yekaterinburg, 2020) [in Russian].

V. F. Sobolev, N. V. Andriyanov, and A. A. Chichko, Lit’e Metall., No. 4 (32), 72 (2004). https://www.elibrary.ru/item.asp?id=50149824.

M. L. Lobanov and M. A. Zorina, Methods for determining diffusion coefficients: A tutorial, (Ural Univ., Yekaterinburg, 2017) [in Russian].

S. M. Kabishov, I. A. Trusova, P. Je. Ratnikov, and S. V. Korneev, Litiyo i Metallurgiya 79 (2), 82, 2015 [in Russian].

L. A. Smirnov, A. G. Gudov, S. P. Burmasov, A. S. Oryshchenko, and G. Yu. Kalinin, Steel in Translation 50 (10), 659 (2020). https://doi.org/10.3103/S0967091220100095

G. V. Shishalova, M. A. Kulakova, and E. E. Varlashova, Analitika i kontrol 7 (2), 186 (2003) [in Russian].

A. A. Pupyshev ans D. A. Danilova, Analitika i kontrol 11 (2–3), 131 (2007) [in Russian].

ACKNOWLEDGEMENTS

The authors thank V.A. Karev for ingot synthesis and I.K. Averkiev for conducting electron microscopic examination and energy-dispersive analysis.

Funding

This study was carried out in the framework of research project no. 121030100001-3 using equipment in the Center for Collective Use at the Udmurt Federal Research Center, Ural Division, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Isaakyan

Publisher’s Note.

Pleiades Publishing remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Konovalov, M.S., Lad’yanov, V.I., Mokrushina, M.I. et al. Influence of Carbon on the Wear Resistance, Strength, and Hardness of Composites with a Fe−Cr–Mn–Mo–N–C Matrix. Tech. Phys. (2024). https://doi.org/10.1134/S1063784224700257

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1134/S1063784224700257