Abstract

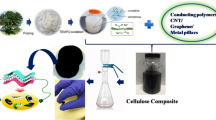

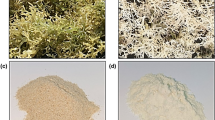

Fiber-based commodities represent a substantial fraction of plastic waste, leading to environmental harm. Discarded sanitary masks and fishing equipment undergo degradation, generating microfiber plastics, thereby presenting a notable hazard to both human health and the ecosystem. In this study, mechanically strong and environmentally friendly nanocomposite fibers were prepared by dry-jet wet spinning. The all-biomass-based fibers comprised agar and cellulose nanocrystals (CNC) as the matrix and nanofiller, respectively, and were highly miscible in deionized water as a cosolvent. Based on rheological characterization, the optimal spinning concentration and temperature were set to 13% (w/v) and 95 °C, respectively. The dry-jet wet-spun agar-based fibers exhibited remarkable mechanical performance compared with previously reported agar-based materials. In particular, the 1 wt% CNC (with respect to the agar amount) simultaneously improved the Young’s modulus, strength, and toughness by 8.3, 4.8, and 16.4% (2.6 GPa, 93.5 MPa, and 7.8 MJ m−3), respectively, compared to those of the control agar fibers (2.4 GPa, 89.2 MPa, and 6.7 MJ m−3), overcoming the trade-off of stiffness-toughness for conventional nanocomposite systems. In addition, the agar/CNC nanocomposite fibers rapidly adsorbed Methylene blue within 90 min, which is significantly faster than that of the film-type agar adsorbent. Therefore, all-biomass-based agar/CNC fibers are a promising remedy for alleviating water pollution.

Similar content being viewed by others

Data availability

Data will be made available on request.

References

Cho WS, Lee JH, Choi SS (2023) Effect of waste PET blending on the physical and chemical characteristics of activated carbons. Macromol Res 31:1021–1027

Nadeem H, Dehghani M, Miri S, Pazirofteh M, Garnier G, Batchelor W (2023) Highly hydrophobic and moisture barrier nanocellulose based films produced via spray deposition. Cellulose 30:5157–5170

de Sousa Junior RR, Dos Santos CAS, Ito NM, Suqueira AN, Lackner M, Dos Santos DJ (2022) PHB processability and property improvement with linear-chain polyester oligomers used as plasticizers. Polymers 14:4197

Li Y, Wei C, Jiang Y, Cheng R, Zhang Y, Ning C, Dong K, Wang ZL (2022) Continuous preparation of chitosan-based self-powered sensing fibers recycled from wasted materials for smart home applications. Adv Fiber Mater 4:1584–1594

Hu T, Shen M, Tang W (2022) Wet wipes and disposable surgical masks are becoming new sources of fiber microplastic pollution during global COVID-19. Environ Sci Pollut Res 29:284–292

Lyu L, Bagchi M, Markoglou N, An C, Peng H, Bi H, Yang X, Sun H (2023) Towards environmentally sustainable management: a review on the generation, degradation, and recycling of polypropylene face mask waste. J Hazard Mater 461:132566

Kozioł A, Paso KG, Kuciel S (2022) Properties and recyclability of abandoned fishing net-based plastic debris. Catalysts 12:948

Tebyetekerwa M, Xu Z, Yang S, Ramakrishna S (2020) Electrospun nanofibers - based face masks. Adv Fiber Mater 2:161

Jonsirivilai B, Torgbo S, Sukyai P (2022) Multifunctional filter membrane for face mask using bacterial cellulose for highly efficient particulate matter removal. Cellulose 29:6205–6218

Kim S, Kim YT, Oh LS, Kim HJ, Lee J (2022) Marine waste upcycling—recovery of nylon monomers from fishing net waste using seashell waste-derived catalysts in a CO 2-mediated thermocatalytic process. J Mater Chem A 10:20024–20034

Buss N, Sander B, Hua J (2022) Effects of polyester microplastic fiber contamination on amphibian–trematode interactions. Environ Toxicol Chem 41:869–879

Cebrián-Lloret V, Martínez-Abad A, López-Rubio A, Martínez-Sanz M (2024) Exploring alternative red seaweed species for the production of agar-based hydrogels for food applications. Food Hydrocoll 146:109177

Wan Y, Liu H, Yan K, Li X, Lu Z, Wang D (2023) An ionic/thermal-responsive agar/alginate wet-spun microfiber-shaped hydrogel combined with grooved/wrinkled surface patterns and multi-functions. Carbohydr Polym 304:120501

Athamneh T, Hajnal A, Al-Najjar MA, Alshweiat A, Obeidat R, Awad AA, Al-Alwany R, Keitel J, Wu D, Kieserling H, Rohn S, Keil C, Gurikov P (2023) In vivo tests of a novel wound dressing based on agar aerogel. Int J Biol Macromol 239:124238

Sarmah D, Borah M, Mandal M, Karak N (2023) Swelling induced mechanically tough starch–agar based hydrogel as a control release drug vehicle for wound dressing applications. J Mater Chem B 11:2927–2936

Bao X, Hayashi K, Li Y, Teramoto A, Abe K (2010) Novel agarose and agar fibers: Fabrication and characterization. Mater Lett 64:2435–2437

Song J, Kim H, Lee SH, Lee O, Kim HJ, Jeong Y, Chae HG, Koo J, Yu S, Eom Y (2023) Rheology-tailored stable aramid nanofiber suspensions for fabricating ultra-strong and electrically insulated additive-free nanopapers. Chem Eng J 475:146394

Chiu YC, Vo TH, Sheng YJ, Tsao HK (2022) Spontaneous formation of microgels for a 3D printing supporting medium. ACS Appl Polym Mater 5:764–774

Kim HJ, Jeong JH, Choi YH, Eom Y (2021) Review on cellulose nanocrystal-reinforced polymer nanocomposites: processing, properties, and rheology. Korea Aust Rheol J 33:165–185

Kassa HS, Jabasingh SA, Mohammed SA, Baek SY, Park SY (2022) Extraction and characterization of cellulose nanocrystals from anchote (Coccinia Abyssinica) Bagasse. Macromol Res 30:776–782

Lee Y, Zhang H, Yu HY, Tam KC (2022) Electroconductive cellulose nanocrystals—Synthesis, properties and applications: a review. Carbohydr Polym 289:119419

Kim HJ, Choi YH, Jeong JH, Kim H, Yang HS, Hwang SY, Koo JM, Eom Y (2021) Rheological percolation of cellulose nanocrystals in biodegradable poly (butylene succinate) nanocomposites: a novel approach for tailoring the mechanical and hydrolytic properties. Macromol Res 29:720–726

Hassan AF, Alshandoudi LM, Awad AM, Mustafa AA, Esmail G (2023) Synthesis of nanomagnetite/copper oxide/potassium carrageenan nanocomposite for the adsorption and Photo-Fenton degradation of Safranin-O: kinetic and thermodynamic studies. Macromol Res 31:677–697

Shin YE, Lee JE, Park Y, Hwang SH, Chae HG, Ko H (2018) Sewing machine stitching of polyvinylidene fluoride fibers: programmable textile patterns for wearable triboelectric sensors. J Mater Chem A 6:22879–22888

Eom Y, Ju H, Kim BC, Chae HG (2019) Enthalpic effect of polyacrylonitrile on the concentrated solutions in dimethyl sulfoxide: strong thixotropic behavior and formation of bound solvents. J Polym Sci Part B Polym Phys 57:1080–1089

Son SM, Lee JE, Jeon J, Lim SI, Kwon HT, Eom Y, Chae HG (2021) Preparation of high-performance polyethersulfone/cellulose nanocrystal nanocomposite fibers via dry-jet wet spinning. Macromol Res 29:33–39

Song J, Choi YH, Kim HJ, Kim H, Eom Y (2023) Control of reinforcing efficiency in thermoplastic polyurethane/aramid nanofiber nanocomposites: rheological and two-dimensional correlation spectroscopic approaches. Eur Polym J 193:112106

Kim H, Kim HJ, Lee Y, Kim JK, Eom Y (2023) Rheological characterization of cellulose nanocrystal-laden self-healable polyvinyl alcohol hydrogels. Korea Aust Rheol J 35:31–38

Seo SB, Lee JE, Ju H, Kim HJ, Eom Y, Chae HG (2022) Mild acid-based surfactant-free solutions of single-walled carbon nanotubes: Highly viscous, less toxic, and humidity-insensitive solutions. Chem Eng J 450:137983

Xiang C, Behabtu N, Liu Y, Chae HG, Young CC, Genorio B, Tsentalovich DE, Zhang C, Kosynkin DV, Lomeda JR, Hwang CC, Kumar S, Pasquali M, Tour JM (2013) Graphene nanoribbons as an advanced precursor for making carbon fiber. ACS Nano 7:1628–1637

Newcomb BA, Gulgunje PV, Gupta K, Kamath MG, Liu Y, Giannuzzi LA, Chae HG, Kumar S (2015) Processing, structure, and properties of gel spun PAN and PAN/CNT fibers and gel spun PAN based carbon fibers. Polym Eng Sci 55:2603–2614

Kanmani P, Rhim JW (2014) Antimicrobial and physical-mechanical properties of agar-based films incorporated with grapefruit seed extract. Carbohydr Polym 102:708–716

Sharma K, Kumar V, Swart-Pistor C, Chaudhary B, Swart HC (2017) Synthesis, characterization, and anti-microbial activity of superabsorbents based on agar–poly (methacrylic acid-glycine). J Bioact Compat Polym 32:74–91

Lee JH, Park SH, Kim SH (2020) Surface alkylation of cellulose nanocrystals to enhance their compatibility with polylactide. Polymers 12:178

Deng H, Chen Q, Xie F, Zhao C, Pan J, Cheng Q, Zhang C (2023) Castor oil-based waterborne polyurethane/tunicate cellulose nanocrystals nanocomposites for wearable strain sensors. Carbohydr Polym 302:120313

Tao R, Shi J, Granier F, Moeini M, Akbarzadeh A, Therriault D (2022) Multi-material fused filament fabrication of flexible 3D piezoelectric nanocomposite lattices for pressure sensing and energy harvesting applications. Appl Mater Today 29:101596

Chang XX, Mubarak NM, Karri RR, Tan YH, Khalid M, Dehghani MH, Tyagi I, Khan NA (2023) Insights into chitosan-based cellulose nanowhiskers reinforced nanocomposite material via deep eutectic solvent in green chemistry. Environ Res 219:115089

Park SA, Eom Y, Jeon H, Koo JM, Lee ES, Jegal J, Hwang SY, Oh DX, Park J (2019) Preparation of synergistically reinforced transparent bio-polycarbonate nanocomposites with highly dispersed cellulose nanocrystals. Green Chem 21:5212–5221

Kanmani P, Rhim JW (2014) Properties and characterization of bionanocomposite films prepared with various biopolymers and ZnO nanoparticles. Carbohydr Polym 106:190–199

Reddy JP, Rhim JW (2014) Characterization of bionanocomposite films prepared with agar and paper-mulberry pulp nanocellulose. Carbohydr Polym 110:480–488

Atef M, Rezaei M, Behrooz R (2014) Preparation and characterization agar-based nanocomposite film reinforced by nanocrystalline cellulose. Int J Biol Macromol 70:537–544

Rhim JW, Reddy JP, Luo X (2015) Isolation of cellulose nanocrystals from onion skin and their utilization for the preparation of agar-based bio-nanocomposites films. Cellulose 22:407–420

Huang S, Xiong Y, Zou Y, Dong Q, Ding F, Liu X, Li H (2019) A novel colorimetric indicator based on agar incorporated with Arnebia euchroma root extracts for monitoring fish freshness. Food Hydrocoll 90:198–205

Davidović S, Lazić V, Miljković M, Gordić M, Sekulić M, Marinović-Cincović M, Ratnayake IS, Ahrenkiel SP, Nedeljković JM (2019) Antibacterial ability of immobilized silver nanoparticles in agar-agar films co-doped with magnesium ions. Carbohydr Polym 224:115187

Roy S, Rhim JW, Jaiswal L (2019) Bioactive agar-based functional composite film incorporated with copper sulfide nanoparticles. Food Hydrocoll 93:156–166

de Araujo CMB, Ghislandi MG, Rios AG, da Costa GRB (2022) Wastewater treatment using recyclable agar-graphene oxide biocomposite hydrogel in batch and fixed-bed adsorption column: bench experiments and modeling for the selective removal of organics. Colloids Surfaces A 639:128357

Betraoui A, Seddiki N, Souag R, Guerfi N, Semlali A, Aouak T, Aliouche D (2023) Synthesis of new hydrogels involving acrylic acid and acrylamide grafted agar-agar and their application in the removal of cationic dyes from wastewater. Gels 9:499

Nguyen TT, Hoang BN, Van Tran T, Van Nguyen D, Nguyen TD, Vo DVN (2021) Agar/maltodextrin/poly (vinyl alcohol) walled montmorillonite composites for removal of methylene blue from aqueous solutions. Surf Interfaces 26:101410

Acknowledgements

This work was supported by the Pukyong National University Industry-university Cooperation Research Fund in 202311990001 and National Research Foundation of Korea (2020R1C1C1009340).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflicts of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, Y., Kim, H.J., Kim, M.W. et al. All-biomass-based strong nanocomposite fibers of agar and cellulose nanocrystals and their dye removal applications. Korea-Aust. Rheol. J. (2024). https://doi.org/10.1007/s13367-024-00089-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13367-024-00089-y