Abstract

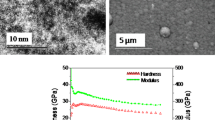

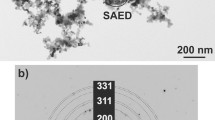

This investigation explores the improvement in mechanical and tribological properties of the Ti6Al7Nb alloy by depositing TaN-Ag (0.5 at.%) nanocomposite coating using magnetron sputtering. The structural properties, morphology, elemental composition, and surface roughness of nanocomposite coating were studied. The effect of nanoindentation load on the hardness (H) and modulus (E) of the substrate and deposited nanocomposite coating was studied. To determine the coefficient of friction and wear rate, tribological tests were performed on the substrate and coating under the applied load range 0.50-1.50 N. Also, scratch test was performed under progressive loading 0-600 mN to determine the critical loads. The results demonstrated that indentation load significantly affects the H, E, and H/E ratio values. The TaN-Ag coating shows reduced wear rate (10−5 mm3/N m) compared to substrate (10−3 mm3/N m). Cracking due to spallation and fine abrasive grooves were main mechanisms responsible for wear of TaN-Ag nanocomposite coating. Raman spectroscopy also confirmed oxide formation during sliding.

Similar content being viewed by others

References

I.C. Lavos-Valereto, S. Wolynec, M.C.Z. Deboni, and B. Knig, In Vitro and In Vivo Biocompatibility Testing of Ti-6Al-7Nb Alloy with and Without Plasma-Sprayed Hydroxyapatite Coating, J. Biomed. Mater. Res., 2001, 58(6), p 727–733. https://doi.org/10.1002/jbm.1072

N.A. Al-Mobarak, A.A. Al-Swayih, and F.A. Al-Rashoud, Corrosion Behavior of Ti-6Al-7Nb Alloy in Biological Solution for Dentistry Applications, Int. J. Electrochem. Sci., 2011, 6(6), p 2031–2042. https://doi.org/10.1016/S1452-3981(23)18165-X

M. Fellah, O. Assala, M. Labaïz, L. Dekhil, and A. Iost, Friction and Wear Behavior of Ti-6Al-7Nb Biomaterial Alloy, J. Biomater. Nanobiotechnol., 2013, 04(04), p 374–384. https://doi.org/10.4236/jbnb.2013.44047

G. Li, Q. Zhao, H. Tang, G. Li, and Y. Chi, Fabrication, Characterization and Biocompatibility of TiO2 Nanotubes via Anodization of Ti6Al7Nb, Compos. Interfaces, 2016, 23(3), p 1–8. https://doi.org/10.1080/09276440.2016.1128723

X.Y. Zheng, Y.R. Zhang, and B.R. Zhang, Effect of N-ion Implantation and Diamond-Like Carbon Coating on Fretting Wear Behaviors of Ti6Al7Nb in Artificial Saliva, Trans. Nonferrous Met. Soc. China, 2017, 27(5), p 1071–1080. https://doi.org/10.1016/S1003-6326(17)60125-0

J. Kim, W.J. Lee, and H.W. Park, Mechanical Properties and Corrosion Behavior of the Nitriding Surface Layer of Ti-6Al-7Nb Using Large Pulsed Electron Beam (LPEB), J. Alloys Compd., 2016, 679, p 138–148. https://doi.org/10.1016/j.jallcom.2016.04.060

M.A. Domínguez-Crespo et al., Effect of Deposition Parameters on Structural, Mechanical and Electrochemical Properties in Ti/TiN Thin Films on AISI 316L Substrates Produced by r. f. Magnetron Sputtering, J. Alloys Compd., 2018, 746, p 688–698. https://doi.org/10.1016/j.jallcom.2018.02.319

A.W. Zia, I. Anestopoulos, M.I. Panayiotidis, and M. Birkett, Soft Diamond-like Carbon Coatings with Superior Biocompatibility for Medical Applications, Ceram. Int., 2023, 49(11), p 17203–17211. https://doi.org/10.1016/j.ceramint.2023.02.085

S.T. Rajan, B. Subramanian, and A. Arockiarajan, A Comprehensive Review on Biocompatible Thin Films for Biomedical Application, Ceram. Int., 2022, 48(4), p 4377–4400.

R. Li et al., Tantalum Nitride Coatings Prepared by Magnetron Sputtering to Improve the Bioactivity and Osteogenic Activity for Titanium Alloy Implants, RSC Adv., 2017, 7(87), p 55408–55417. https://doi.org/10.1039/c7ra09032c

A.M. Echavarría, P. Rico, J.G. Ribelles, M.A. Pacha-Olivenza, M.C. Fernández-Calderón, and G. Bejarano-G, Development of a Ta/TaN/TaNx (Ag) y/TaN Nanocomposite Coating System and Bio-Response Study for Biomedical Applications, Vacuum, 2017, 145, p 55–67. https://doi.org/10.1016/j.vacuum.2017.08.020

L. Gladczuk, A. Patel, J.D. Demaree, and M. Sosnowski, Sputter Deposition of bcc Tantalum Films with TaN underlayers for Protection of Steel, Thin Solid Films, 2005, 476(2), p 295–302. https://doi.org/10.1016/j.tsf.2004.10.020

L. Shi, Z. Yang, L. Chen, and Y. Qian, Synthesis and Characterization of Nanocrystalline TaN, Solid State Commun., 2005, 133(2), p 117–120. https://doi.org/10.1016/j.ssc.2004.10.004

K. Valleti, A. Subrahmanyam, S.V. Joshi, A.R. Phani, M. Passacantando, and S. Santucci, Studies on Phase Dependent Mechanical Properties of dc Magnetron Sputtered TaN Thin Films: Evaluation of Super Hardness in Orthorhombic Ta4N Phase, J. Phys. D Appl. Phys., 2008, 41(4), p 045409. https://doi.org/10.1088/0022-3727/41/4/045409

S.S. Firouzabadi, M. Naderi, K. Dehghani, and F. Mahboubi, Effect of Nitrogen Flow Ratio on Nano-Mechanical Properties of Tantalum Nitride Thin Film, J. Alloys Compd., 2017, 719, p 63–70. https://doi.org/10.1016/j.jallcom.2017.05.159

J. Corona-Gomez, T.A. Jack, R. Feng, and Q. Yang, Wear and Corrosion Characteristics of Nano-Crystalline Tantalum Nitride Coatings Deposited on CoCrMo Alloy for Hip Joint Applications, Mater Charact, 2021, 182, p 111516. https://doi.org/10.1016/j.matchar.2021.111516

K.Y. Liu, J.W. Lee, and F.B. Wu, Fabrication and Tribological Behavior of Sputtering TaN Coatings, Surf. Coat. Technol., 2014, 259, p 123–128. https://doi.org/10.1016/j.surfcoat.2014.03.024

H.L. Huang, Y.Y. Chang, M.C. Lai, C.R. Lin, C.H. Lai, and T.M. Shieh, Antibacterial TaN-Ag Coatings on Titanium Dental Implants, Surf. Coat. Technol., 2010, 205(5), p 1636–1641. https://doi.org/10.1016/j.surfcoat.2010.07.096

C. Zhao, H. Wu, P. Hou, J. Ni, P. Han, and X. Zhang, Enhanced Corrosion Resistance and Antibacterial Property of Zn Doped DCPD Coating on Biodegradable Mg, Mater. Lett., 2016, 180, p 42–46. https://doi.org/10.1016/j.matlet.2016.04.035

H. Wang, B. Tang, X. Li, and Y. Ma, Antibacterial Properties and Corrosion Resistance of Nitrogen-doped TiO2 Coatings on Stainless Steel, J. Mater. Sci. Technol., 2011, 27(4), p 309–316. https://doi.org/10.1016/S1005-0302(11)60067-4

P. Ren, X. Yang, S. Zhang, J. Qiu, Y. Li, L. Han, J. Zhang, and M. Wen, Enhanced Self-Lubricating and Antibacterial Activity by Building Hard-yet-Tough Ta-Ag-N films on Ti-6Al-4V, Surf. Coat. Technol., 2020, 403, p 126423. https://doi.org/10.1016/j.surfcoat.2020.126423

J.H. Hsieh, T.H. Yeh, C. Li, S.Y. Chang, C.H. Chiu, and C.T. Huang, Mechanical Properties and Antibacterial Behaviors of TaN-(Ag, Cu) Nanocomposite Thin Films After Annealing, Surf. Coat. Technol., 2013, 228(SUPPL.1), p 116–119. https://doi.org/10.1016/j.surfcoat.2012.07.022

L. Swiatek et al., Multi-Doped Diamond Like-Carbon Coatings (DLC-Si/Ag) for Biomedical Applications Fabricated using the Modified Chemical Vapour Deposition Method, Diam. Relat. Mater., 2016, 67, p 54–62. https://doi.org/10.1016/j.diamond.2016.03.005

M. Ren, H.L. Yu, L.N. Zhu, H.Q. Li, H.D. Wang, Z.G. Xing, and B.S. Xu, Microstructure, Mechanical Properties and Tribological Behaviors of TiAlN-Ag Composite Coatings by Pulsed Magnetron Sputtering Method, Surf. Coat. Technol., 2022, 436, p 128286. https://doi.org/10.1016/j.surfcoat.2022.128286

ASTM International, ASTM G99-17, Standard Test Method for Wear Testing with a Pin-On-Disk Apparatus Annual Book of ASTM Standards. (2017). https://doi.org/10.1520/G0099-17

S.H. Mukhtar, M.F. Wani, R. Sehgal, and M.D. Sharma, Nano-Mechanical and Nano-Tribological Characterisation of Self-Lubricating MoS2 Nano-Structured Coating for Space Applications, Tribol. Int., 2023, 178, p 108017. https://doi.org/10.1016/j.triboint.2022.108017

S.M. Wani, B. Ahmad, and S.S. Saleem, Nano-Mechanical and Nano-Tribological Characterization of Ni-Co-BN Nano-Composite Coating for Bearing Applications, Tribol. Int., 2023, 180, p 108281. https://doi.org/10.1016/j.triboint.2023.108281

H. Ju, L. Yu, D. Yu, I. Asempah, and J. Xu, Microstructure, Mechanical and Trobological Properties of TiN-Ag Films Deposited by Reactive Magnetron Sputtering, Vacuum, 2017, 141, p 82–88. https://doi.org/10.1016/j.vacuum.2017.03.026

A.L. Patterson, The Scherrer Formula for X-Ray Particle Size Determination, Phys. Rev., 1939, 56(10), p 978–982. https://doi.org/10.1103/PhysRev.56.978

F. Şenaslan, M. Taşdemir, A. Çelik, and Y.B. Bozkurt, Enhanced Wear Resistance and Surface Properties of Oxide Film Coating on Biocompatible Ti45Nb Alloy by Anodization Method, Surf. Coat. Technol., 2023, 469, p 129797. https://doi.org/10.1016/j.surfcoat.2023.129797

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus using Load And Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564–1583. https://doi.org/10.1557/JMR.1992.1564

Z. Mei et al., Determination of Hardness and Fracture Toughness of Y-TZP Manufactured by Digital Light Processing through the Indentation Technique, Biomed. Res. Int., 2021 https://doi.org/10.1155/2021/6612840

V.S. Kathavate, B. Praveen Kumar, I. Singh, and K. Eswar Prasad, Analysis of Indentation Size Effect (ISE) in Nanoindentation Hardness in Polycrystalline PMN-PT Piezoceramics with Different Domain Configurations, Ceram. Int., 2021, 47(9), p 11870–11877. https://doi.org/10.1016/j.ceramint.2021.01.027

S.J. Bull, T.F. Page and E.H. Yoffe, An Explanation of the Indentation Size Effect in Ceramics, Philos. Mag. Lett., 1989, 59(6), p 281–288. https://doi.org/10.1080/09500838908206356

B.D. Beake, The Influence of the H/E Ratio on Wear Resistance of Coating Systems—Insights from Small-Scale Testing, Surf. Coat. Technol., 2022, 442, p 128272. https://doi.org/10.1016/j.surfcoat.2022.128272

R. Akhter, Z. Zhou, Z. Xie, and P. Munroe, Harmonizing Mechanical Responses of Nanostructured CrN Coatings via Ni Additions, Appl. Surf. Sci., 2021, 538, p 147987. https://doi.org/10.1016/j.apsusc.2020.147987

M. Barletta, V. Tagliaferri, A. Gisario, and S. Venettacci, Progressive and Constant Load Scratch Testing of Single- and Multi-Layered Composite Coatings, Tribol. Int., 2013, 64, p 39–52. https://doi.org/10.1016/j.triboint.2013.03.002

G. Melnikova et al., Nanomechanical and Nanotribological Properties of Nanostructured Coatings of Tantalum and its Compounds on Steel Substrates, Nanomaterials, 2021, 11(9), p 2407. https://doi.org/10.3390/nano11092407

C.D. Rivera-Tello et al., Micro and Macro-Tribology Behavior of a Hierarchical Architecture of a Multilayer TaN/Ta Hard Coating, Coatings, 2020, 10(3), p 263. https://doi.org/10.3390/coatings10030263

S.K. Singh, S. Chattopadhyaya, A. Pramanik, and S. Kumar, Wear Behavior of Chromium Nitride Coating in Dry Condition at lower Sliding Velocity and Load, Int. J. Adv. Manuf. Technol., 2018, 96(5–8), p 1665–1675. https://doi.org/10.1007/s00170-017-0796-x

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 2004, 24(8), p 981–988. https://doi.org/10.1063/1.1721448

S. Kumar, R. Sehgal, M.F. Wani, and M.D. Sharma, Friction and Wear Properties of Core-Shell (CI is a Core & GO is a Shell) Particles Based Magnetorheological Fluid under Steel on Steel Point Contacts, J. Ind. Eng. Chem., 2022, 118, p 446–457. https://doi.org/10.1016/j.jiec.2022.11.028

J. Bansal et al., Performance Analysis of Anomalous Photocatalytic Activity of Cr-doped TiO2 Nanoparticles [Cr(x)TiO2(1–x)], Appl. Phys. A Mater. Sci. Process., 2020, 126(5), p 1–11. https://doi.org/10.1007/s00339-020-03536-z

N. Hossain et al., Structural and Physical Properties of NbO2 and Nb2O5 Thin Films Prepared by Magnetron Sputtering, J. Mater. Sci. Mater. Electron., 2019, 30(10), p 9822–9835. https://doi.org/10.1007/s10854-019-01319-8

G. Welsch and A.I. Kahveci, Oxidation Behavior of Titanium Aluminide Alloys, Oxidation of High-Temperature Intermetallics. T. Grobstein, J. Doychak Ed., Springer, Berlin, 1988, p 207–218

M.O. Alam and A.S.M.A. Haseeb, Response of Ti-6Al-4V and Ti-24Al-11Nb Alloys to Dry Sliding Wear against Hardened Steel, Tribol. Int., 2002, 35(6), p 357–362. https://doi.org/10.1016/S0301-679X(02)00015-4

Acknowledgments

Authors acknowledge the facilities provided by CRFC, National Institute of Technology Srinagar (J&K), India, for experimental work, and the technical help received from the staff, and the guidance received from others associated with the CRFC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, V., Sharma, R.K. & Sehgal, R. A Comprehensive Investigation on Nanomechanical, Scratch, and Tribological Characteristics of TaN-Ag Nanocomposite Coating on Ti6Al7Nb Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09408-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09408-4