Abstract

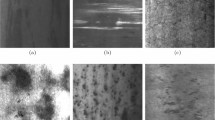

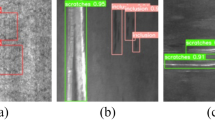

Deep learning algorithms have gained widespread usage in defect detection systems. However, existing methods are not satisfied for large-scale applications on surface defect detection of strip steel. In this paper, we propose a precise and efficient detection model, named CABF-YOLO, based on the YOLOX for strip steel surface defects. Firstly, we introduce the Triplet Convolutional Coordinate Attention (TCCA) module in the backbone of the YOLOX. By factorizing the pooling operation, the TCCA module can accurately capture cross-channel features to identify the location information of defects. Secondly, we design a novel Bidirectional Fusion (BF) strategy in the neck of the YOLOX. The BF strategy enhances the fusion of low-level and high-level semantic information to obtain fine-grained information. Lastly, the original bounding box loss function is replaced by the EIoU loss function. In the EIoU loss function, the penalty term is redefined to consider the overlap area, central point, and side length of the required regressions to accelerate the convergence rate and localization accuracy. On the benchmark NEU-DET dataset and GC10-DET dataset, the experimental results show that the CABF-YOLO achieves superior performance compared with other comparison models and satisfies the real-time detection requirement of industrial production.

Similar content being viewed by others

Data availability

The NEU-DET dataset analysed in the current study is openly available in the UCI repository at http://faculty.neu.edu.cn/songkechen/zh_CN/zdylm/263270/list/index.html. The GC10-DET dataset analysed in the current study is available in the GitHub repository at https://github.com/lvxiaoming2019/GC10-DET-Metallic-Surface-Defect-Datasets.git.

References

Yu J, Cheng X, Li Q (2022) Surface defect detection of steel strips based on anchor-free network with channel attention and bidirectional feature fusion. IEEE Trans Instrum Meas 71:1–10

Luo Q, Fang X, Sun Y, Liu L, Ai J, Yang C, Simpson O (2019) Surface defect classification for hot-rolled steel strips by selectively dominant local binary patterns. IEEE Access 7:23488–23499

Hou Z, Parker JM (2005) Texture defect detection using support vector machines with adaptive Gabor wavelet features. In: 2005 Seventh IEEE Workshops on Applications of Computer Vision (WACV/MOTION’05), vol 1, pp 275–280

Ghorai S, Mukherjee A, Gangadaran M, Dutta PK (2012) Automatic defect detection on hot-rolled flat steel products. IEEE Trans Instrum Meas 62(3):612–621

Xu K, Ai Y-H, Wu X-Y (2013) Application of multi-scale feature extraction to surface defect classification of hot-rolled steels. Int J Miner Metall Mater 20:37–41

Pernkopf F (2004) Detection of surface defects on raw steel blocks using Bayesian network classifiers. Pattern Anal Appl 7:333–342

Xue-Wu Z, Yan-Qiong D, Yan-Yun L, Ai-Ye S, Rui-Yu L (2011) A vision inspection system for the surface defects of strongly reflected metal based on multi-class SVM. Expert Syst Appl 38(5):5930–5939

Girshick R, Donahue J, Darrell T, Malik J (2014) Rich feature hierarchies for accurate object detection and semantic segmentation. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 580–587

Girshick R (2015) Fast R-CNN. In: Proceedings of the IEEE international conference on computer vision, pp 1440–1448

Ren S, He K, Girshick R, Sun J, Faster R-CNN: towards real-time object detection with region proposal networks. Adv Neural Inf Processing Syst 28

Redmon J, Divvala S, Girshick R, Farhadi A (2016) You only look once: unified, real-time object detection. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 779–788

Redmon J, Farhadi A (2017) YOLO9000: better, faster, stronger. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 7263–7271

Lin T-Y, Goyal P, Girshick R, He K, Dollár P (2017) Focal loss for dense object detection. In: Proceedings of the IEEE international conference on computer vision, pp 2980–2988

Lin T-Y, Dollár P, Girshick R, He K, Hariharan B, Belongie S (2017) Feature pyramid networks for object detection. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 2117–2125

Redmon J, Farhadi A (2018) YOLOv3: an incremental improvement. arXiv:1804.02767

Alexey B, Wang C, Mark Liao H (2020) Optimal speed and accuracy of object detection. arXiv:2004.10934

Jocher G (2021) YOLOv5 by ultralytics. https://doi.org/10.5281/zenodo.3908559

Ge Z, Liu S, Wang F, Li Z, Sun J (2021) YOLOX: exceeding YOLO series in 2021. arXiv:2107.08430

Li C, Li L, Jiang H, Weng K, Geng Y, Li L, Ke Z, Li Q, Cheng M, Nie W et al (2022) Yolov6: a single-stage object detection framework for industrial applications. arXiv:2209.02976

Ding X, Zhang X, Ma N, Han J, Ding G, Sun J (2021) RepVGG: making VGG-style convnets great again. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 13733–13742

Wang C-Y, Bochkovskiy A, Liao H-YM (2023) Yolov7: trainable bag-of-freebies sets new state-of-the-art for real-time object detectors. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 7464–7475

Jocher G, Chaurasia A, Qiu J (2023) YOLO by Ultralytics. https://github.com/ultralytics/ultralytics

He Y, Song K, Meng Q, Yan Y (2019) An end-to-end steel surface defect detection approach via fusing multiple hierarchical features. IEEE Trans Instrum Meas 69(4):1493–1504

Lv X, Duan F, Jiang J-J, Fu X, Gan L (2020) Deep metallic surface defect detection: the new benchmark and detection network. Sensors 20(6):1562

Kou X, Liu S, Cheng K, Qian Y (2021) Development of a YOLO-V3-based model for detecting defects on steel strip surface. Measurement 182:109454

Zhao W, Chen F, Huang H, Li D, Cheng W (2021) A new steel defect detection algorithm based on deep learning. Comput Intell Neurosci 2021:1–13

Tian R, Jia M (2022) DCC-CenterNet: a rapid detection method for steel surface defects. Measurement 187:110211

Yu X, Lyu W, Zhou D, Wang C, Xu W (2022) ES-Net: Efficient scale-aware network for tiny defect detection. IEEE Trans Instrum Meas 71:1–14

Wang W, Mi C, Wu Z, Lu K, Long H, Pan B, Li D, Zhang J, Chen P, Wang B (2022) A real-time steel surface defect detection approach with high accuracy. IEEE Trans Instrum Meas 71:1–10

Guo Z, Wang C, Yang G, Huang Z, Li G (2022) MSFT-YOLO: improved YOLOv5 based on transformer for detecting defects of steel surface. Sensors 22(9):3467

Wang Y, Wang H, Xin Z (2022) Efficient detection model of steel strip surface defects based on YOLO-V7. IEEE Access 10:133936–133944

Zhou X, Wei M, Li Q, Fu Y, Gan Y, Liu H, Ruan J, Liang J (2023) Surface defect detection of steel strip with double pyramid network. Appl Sci 13(2):1054

Liu R, Huang M, Gao Z, Cao Z, Cao P (2023) MSC-DNet: an efficient detector with multi-scale context for defect detection on strip steel surface. Measurement 209:112467

Chen H, Du Y, Fu Y, Zhu J, Zeng H (2023) DCAM-Net: a rapid detection network for strip steel surface defects based on deformable convolution and attention mechanism. IEEE Trans Instrum Meas 72:1–12

Zhang Y, Zhang H, Huang Q, Han Y, Zhao M (2024) DsP-YOLO: an anchor-free network with DsPAN for small object detection of multiscale defects. Expert Syst Appl 241:122669

Zhang Y-F, Ren W, Zhang Z, Jia Z, Wang L, Tan T (2022) Focal and efficient IOU loss for accurate bounding box regression. Neurocomputing 506:146–157

Song K, Yan Y (2013) A noise robust method based on completed local binary patterns for hot-rolled steel strip surface defects. Appl Surf Sci 285:858–864

Hou Q, Zhou D, Feng J (2021) Coordinate attention for efficient mobile network design. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 13713–13722

Li D, Hu J, Wang C, Li X, She Q, Zhu L, Zhang T, Chen Q (2021) Involution: inverting the inherence of convolution for visual recognition. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 12321–12330

Sunkara R, Luo T (2022) No more strided convolutions or pooling: a new CNN building block for low-resolution images and small objects. arXiv:2208.03641

Hu J, Shen L, Sun G (2018) Squeeze-and-excitation networks. In: Proceedings of the IEEE conference on computer vision and pattern recognition, pp 7132–7141

Woo S, Park J, Lee J-Y, Kweon IS (2018) CBAM: convolutional block attention module. In: Proceedings of the European conference on computer vision (ECCV), pp 3–19

Wang Q, Wu B, Zhu P, Li P, Zuo W, Hu Q (2020) ECA-net: efficient channel attention for deep convolutional neural networks. In: Proceedings of the IEEE/CVF conference on computer vision and pattern recognition, pp 11534–11542

Funding

The authors declare that they have not received funding from any organization with respect to the submitted work.

Author information

Authors and Affiliations

Contributions

Author Qiqi Zhou designed the model and executed experiments, analyzed the performance results of the model, and prepared the original manuscript draft. Author Haichao Wang provided essential theoretical insights and critically revised the manuscript for important intellectual content. All authors read and approved the final manuscript prior to submission

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no Conflict of interest.

Ethical Approval

This declaration is not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, Q., Wang, H. CABF-YOLO: a precise and efficient deep learning method for defect detection on strip steel surface. Pattern Anal Applic 27, 36 (2024). https://doi.org/10.1007/s10044-024-01252-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10044-024-01252-5