Abstract

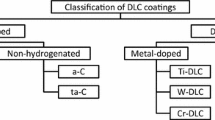

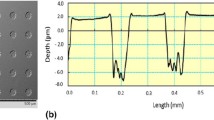

DLC coatings are well known for their high fracture toughness, however, often exhibit poor adhesion properties on metallic substrates. The use of interlayers and metallic doping can be used to overcome such challenge. In this study duplex CrN/DLC and nano-multilayer DLC-W coatings were both deposited on hydraulic valve tappet using a hybrid PVD/PECVD deposition system. Microhardness measurements were taken for the uncoated valve tappet, duplex CrN/DLC and nano-multilayer DLC-W coated valve tappet at loads of 0.98 N, 1.96 N, 2.94 N, 4.9 N, 9.8 N and 19.6 N for 15 seconds using a Shimadzu hardness tester. The fracture toughness was evaluated using the Vickers indentation method from microhardness indents on the surface of the coatings. The fracture toughness for duplex CrN/DLC and nano-multilayer DLC-W coatings indented at 4.9 N, 9.8 N and 19.6 N, reveals that the fracture toughness for the duplex CrN/DLC were 20.24 ± 0.97 MPa.m1/2, 17.18 ± 0.86 MPa.m1/2 and 6.6 ± 0.28 MPa.m1/2 respectively. While the fracture toughness for nano-multilayer DLC-W was calculated as 3.75 ± 0.41 MPa.m1/2 and 4.67 ± 0.38 MPa.m1/2 at 9.8 N and 19.6 N respectively.

Similar content being viewed by others

References

Dearnley P A, Neville A, Turner S, Scheibe H J, Tietema R, Tap R, Stuber M, Hovsepian P, Layyous A and Stenbom B 2010 Coatings tribology drivers for high density plasma technologies. Surf. Eng. 26(1–2): 80–96

Robertson J 2002 Diamond-like amorphous carbon. Mater. Sci. Eng. 37: 129–281

Grill A 1993 Review of the tribology of diamond-like carbon. Wear 168(1993): 143–153

Britun N, Konstantinidis S and Snyders R 2016 Diagnostics of magnetron sputtering discharges by resonant absorption spectroscopy. In: Plasma science and technology - progress in physical states and chemical reactions (ed) Mieno T, IntechOpen, United Kingdom, pp 323–356

Sniderman D 2016 Coatings and engineering are shaping tomorrow’ s world, Tribol. Lubric. Techn. 52-63

Mutafov P, Lanigan J, Neville A, Cavaleiro A and Polcar T 2014 DLC-W coatings tested in combustion engine—frictional and wear analysis. Surf. Coat. Techn. 260: 284–289

Erdemir A and Holmberg K 2015 Energy consumption due to friction in motored vehicles and low-friction coatings to reduce it. In: Coating technology for vehicle applications (eds) Cha S C and Erdemir A, Springer International Publishing AG, Cham, Switzerland, pp 10–15

Kolawole F O, Varela L B, Kolawole S K, Ramirez M A and Tschiptschin A P 2021 Deposition and characterization of tungsten oxide (WO3) nanoparticles incorporated diamond-like carbon coatings using pulsed-DC PECVD. Mater. Lett. 282: 1–4

Kolawole F O, Ramirez M A, Kolawole S K, Varela L B and Tschiptschin A P 2020 Deposition and characterization of molybdenum oxide (MoO3) nanoparticles incorporated diamond-like carbon coatings using pulsed-DC PECVD. Mater. Lett. 278: 1–4

Kolawole F O, Kolade O S, Bello S A, Kolawole S K, Ayeni A T and Elijah T F, Borisade S G and Tschiptschin A P 2023 The improvement of diamond-like carbon coatings for tribological and tribo-corrosion applications in automobile engines: an updated review study. Intern. J. Adv. Manuf. Technol. 126: 2295–2322

Kolawole F O 2023 Mechanical and temperature-dependent tribological behavior of CrN/DLC and multilayer DLC-W coatings for automobile engine applications, PhD Dissertation, University of Sao Paulo, Brazil

Chen X, Du Y and Chung Y W 2019 Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings. Thin Solid Film. 688: 1–7

Nemati N, Bozorg M, Penkov O V, Shin D, Sadighzadeh A and Kim D E 2017 Functional multi-nanolayer coatings of amorphous carbon/tungsten carbide with exceptional mechanical durability and corrosion resistance. ACS Appl. Mater. Interface 9: 30149–30160

Anstis G R, Chantikul P, Lawn B R and Marshall D B 1981 A critical evaluation of indentation techniques for measuring fracture toughness: I, direct crack measurements. J. Am. Ceram. Soc. 64: 533–538

Zhang S, Sun D, Fu Y and Du H 2005 Toughness measurement of thin films: a critical review. Surf. Coat. Technol. 198: 74–84

Yamada Y, Murashima M, Umehara N, Tokoroyama T, Lee W-Y and Takamatsu H, Tanaka Y and Utsumi Y 2022 Effect of fracture properties and surface morphology on wear of DLC coatings at severe contact condition. Tribol. Int. 169: 1–13.

Jeng Y R, Islam S, Wu K T, Erdemir A and Eryilmaz O 2017 Investigation of nano-mechanical and- tribological properties of hydrogenated diamond like carbon (DLC) coatings. J. Mech. 33: 769–776

Schiffmann K I 2011 Determination of fracture toughness of bulk materials and thin films by nanoindentation: comparison of different models. Philos. Mag. 91: 1163–1178

Zia A W, Zhou Z, Shum P W and Li L K Y 2017 The effect of two-step heat treatment on hardness, fracture toughness, and wear of different biased diamond-like carbon coatings. Surf. Coat. Technol. 320: 118–125

Kolawole F O, Santos M D, Kolawole S K, Vencovsky P K, Ludewigs D A and Tschiptschin A P 2023 Nano-scratch and micro-scratch properties of duplex layer CrN/DLC and nano-multilayer DLC-W coatings. Mater. Perform. Character. 12(3): 1–21

Tschiptschin A P 2013 Duplex coatings. In: Encyclopedia of tribology (eds) Wang Q J and Chung Y W, Springer, New York, pp 794–800

Nastasi M, Kodali P, Walter K C, Embury J D, Raj R and Nakamura Y 1999 Fracture toughness of diamondlike carbon coatings. J. Mater. Res. 14: 2173–2180

Hedenqvist P and Hogmark S 1997 Experiences from scratch testing of tribological PVD coatings. Tribol. Int. 30: 507–516

Acknowledgement

The authors are grateful to HEF Durferrit, Brazil for the deposition of the coatings. This work was supported by Fundação de Amparo à Pesquisa do Estado de São Paulo (FAPESP), grant # 2023/08065-6, 2022/05578-0, Petroleum Technology Development Funds (PTDF), Nigeria and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) – Brazil process 141991/2019-4 for financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kolawole, F.O., Kolawole, S.K., Bello, S.A. et al. Fracture toughness of duplex CrN/DLC and nano-multilayer DLC-W deposited on valve tappet via hybrid PVD and PECVD. Sādhanā 49, 127 (2024). https://doi.org/10.1007/s12046-024-02490-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-024-02490-3