Abstract

This study evaluates the impact of a 4-h alkali treatment, using various concentrations of NaOH (2.5%, 5%, 7.5%, 10%, and 15% w/v), on Calamus tenuis cane fibers (CTCFs). Chemical analysis reveals a significant increase in cellulose content, reaching 50.07 ± 1.67% in CTCFs treated with 7.5% NaOH, accompanied by reductions in hemicellulose and lignin as confirmed by FTIR analysis. XRD analysis shows improved structural stability with an enhanced crystallinity index of 44.47 ± 0.69% and crystallite size of 3.03 ± 0.18 nm for CTCFs treated with 7.5% NaOH. TGA analysis indicates decreased activation energy and thermal stability post-treatment. Moreover, CTCFs treated with 7.5% NaOH exhibit peak values of Young’s modulus (2.33 ± 0.05 GPa) and tensile strength (61.37 ± 1.05 MPa). SEM and AFM analyses confirm increased roughness post-treatment, enhancing fiber-matrix interlocking during composite fabrication. EDX analysis identifies an increased O/C ratio post-treatment, suggesting efficient removal of non-cellulosic elements. In conclusion, treating CTCFs with 7.5% NaOH for 4 h at ambient temperature enhances their physicochemical, structural, mechanical, and surface properties, indicating their potential for advanced polymer composites.

Graphical Abstract

Similar content being viewed by others

Data availability

There is no dataset provided with this submission.

References

Xia L, Zhang C, Wang A et al (2020) Morphologies and properties of Juncus effusus fiber after alkali treatment. Cellulose 27:1909–1920. https://doi.org/10.1007/s10570-019-02933-9

Shanmugasundaram N, Rajendran I, Ramkumar T (2018) Characterization of untreated and alkali treated new cellulosic fiber from an Areca palm leaf stalk as potential reinforcement in polymer composites. Carbohydr Polym 195:566–575. https://doi.org/10.1016/j.carbpol.2018.04.127

Sari NH, Sanjay MR, Arpitha GR et al (2019) Synthesis and properties of pandanwangi fiber reinforced polyethylene composites: evaluation of dicumyl peroxide (DCP) effect. Compos Commun 15:53–57. https://doi.org/10.1016/j.coco.2019.06.007

Rangappa SM, Siengchin S, Parameswaranpillai J et al (2022) Lignocellulosic fiber reinforced composites: progress, performance, properties, applications, and future perspectives. Polym Compos 43:645–691. https://doi.org/10.1002/pc.26413

Jagadeesh P, Puttegowda M, Thyavihalli Girijappa YG et al (2022) Effect of natural filler materials on fiber reinforced hybrid polymer composites: an overview. J Nat Fibers 19:4132–4147. https://doi.org/10.1080/15440478.2020.1854145

Sanjay MR, Madhu P, Jawaid M et al (2018) Characterization and properties of natural fiber polymer composites: a comprehensive review. J Clean Prod 172:566–581. https://doi.org/10.1016/j.jclepro.2017.10.101

Widodo E, Pratikto S, Widodo TD (2024) Comprehensive investigation of raw and NaOH alkalized sansevieria fiber for enhancing composite reinforcement. Case Stud Chem Environ Eng 9:100546. https://doi.org/10.1016/j.cscee.2023.100546

Shibly MAH, Islam MdI, Rahat MdNH et al (2024) Extraction and characterization of a novel cellulosic fiber derived from the bark of Rosa hybrida plant. Int J Biol Macromol 257:128446. https://doi.org/10.1016/j.ijbiomac.2023.128446

Ovalı S (2023) Characterization of lignocellulosic glycyrrhiza glabra fibers as a potential reinforcement for polymer composites. J Thermoplast Compos Mater 36:4241–4256. https://doi.org/10.1177/08927057231151928

Youbi SBT, Tagne NRS, Harzallah O et al (2022) Effect of alkali and silane treatments on the surface energy and mechanical performances of Raphia vinifera fibres. Ind Crops Prod 190:115854. https://doi.org/10.1016/j.indcrop.2022.115854

Shahril SM, Ridzuan MJM, Majid MSA et al (2022) Alkali treatment influence on cellulosic fiber from Furcraea foetida leaves as potential reinforcement of polymeric composites. J Mater Res Technol 19:2567–2583. https://doi.org/10.1016/j.jmrt.2022.06.002

Manimaran P, Senthamaraikannan P, Sanjay MR et al (2018) Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr Polym 181:650–658. https://doi.org/10.1016/j.carbpol.2017.11.099

Arul Marcel Moshi A, Ravindran D, Sundara Bharathi SR et al (2020) Characterization of surface-modified natural cellulosic fiber extracted from the root of Ficus religiosa tree. Int J Biol Macromol 156:997–1006. https://doi.org/10.1016/j.ijbiomac.2020.04.117

Gerald Arul Selvan MT, Binoj JS, Mansingh BB, Baby Sajin JA (2023) Physico-chemical properties of alkali treated cellulosic fibers from fragrant screw pine prop root. J Nat Fibers 20:148–161. https://doi.org/10.1080/15440478.2022.2129897

Tenazoa C, Savastano H, Charca S et al (2021) The effect of alkali treatment on chemical and physical properties of ichu and cabuya fibers. J Nat Fibers 18:923–936. https://doi.org/10.1080/15440478.2019.1675211

Umashankaran M, Gopalakrishnan S (2021) Effect of sodium hydroxide treatment on physico-chemical, thermal, tensile and surface morphological properties of Pongamia pinnata L. bark fiber. J Nat Fibers 18:2063–2076. https://doi.org/10.1080/15440478.2019.1711287

Dayo AQ, Zegaoui A, Nizamani AA et al (2018) The influence of different chemical treatments on the hemp fiber/polybenzoxazine based green composites: mechanical, thermal and water absorption properties. Mater Chem Phys 217:270–277. https://doi.org/10.1016/J.MATCHEMPHYS.2018.06.040

Ly E, hadji B, Bras J, Sadocco P, et al (2010) Surface functionalization of cellulose by grafting oligoether chains. Mater Chem Phys 120:438–445. https://doi.org/10.1016/J.MATCHEMPHYS.2009.11.032

M.R. S, Siengchin S, Parameswaranpillai J, et al (2019) A comprehensive review of techniques for natural fibers as reinforcement in composites: preparation, processing and characterization. Carbohydr Polym 207:108–121. https://doi.org/10.1016/j.carbpol.2018.11.083

Baskaran PG, Kathiresan M, Pandiarajan P (2022) Effect of alkali-treatment on structural, thermal, tensile properties of Dichrostachys cinerea bark fiber and its composites. J Nat Fibers 19:433–449. https://doi.org/10.1080/15440478.2020.1745123

Bezazi A, Boumediri H, Garcia del Pino G et al (2022) Alkali treatment effect on physicochemical and tensile properties of date palm rachis fibers. J Nat Fibers 19:3770–3787. https://doi.org/10.1080/15440478.2020.1848726

Rajeshkumar G, Hariharan V, Indran S et al (2021) Influence of sodium hydroxide (NaOH) treatment on mechanical properties and morphological behaviour of phoenix sp. fiber/epoxy composites. J Polym Environ 29:765–774. https://doi.org/10.1007/s10924-020-01921-6

Ben Sghaier AEO, Chaabouni Y, Msahli S, Sakli F (2012) Morphological and crystalline characterization of NaOH and NaOCl treated Agave americana L. fiber. Ind Crops Prod 36:257–266. https://doi.org/10.1016/j.indcrop.2011.09.012

Vijay R, Vinod A, Lenin Singaravelu D et al (2021) Characterization of chemical treated and untreated natural fibers from Pennisetum orientale grass- a potential reinforcement for lightweight polymeric applications. Int J Lightweight Mater Manuf 4:43–49. https://doi.org/10.1016/j.ijlmm.2020.06.008

Mohammed AA, Bachtiar D, Rejab MRM et al (2018) Effects of KMnO4 treatment on the flexural, impact, and thermal properties of sugar palm fiber-reinforced thermoplastic polyurethane composites. JOM 70:1326–1330. https://doi.org/10.1007/s11837-018-2869-1

Palanisamy S, Mayandi K, Dharmalingam S et al (2022) Tensile properties and fracture morphology of Acacia caesia bark fibers treated with different alkali concentrations. J Nat Fibers 19:11258–11269. https://doi.org/10.1080/15440478.2021.2022562

Saravanakumar SS, Kumaravel A, Nagarajan T et al (2013) Characterization of a novel natural cellulosic fiber from Prosopis juliflora bark. Carbohydr Polym 92:1928–1933. https://doi.org/10.1016/j.carbpol.2012.11.064

Negawo TA, Polat Y, Buyuknalcaci FN et al (2019) Mechanical, morphological, structural and dynamic mechanical properties of alkali treated Ensete stem fibers reinforced unsaturated polyester composites. Compos Struct 207:589–597. https://doi.org/10.1016/j.compstruct.2018.09.043

Abral H, Gafar MF, Andriyanto H et al (2012) Alkali treatment of screw pine (Pandanus odoratissimus) fibers and its effect on unsaturated polyester composites. Polym Plast Technol Eng 51:12–18. https://doi.org/10.1080/03602559.2011.593090

Jang ES, Kang CW (2019) Changes in gas permeability and pore structure of wood under heat treating temperature conditions. J Wood Sci 65. https://doi.org/10.1186/s10086-019-1815-3

Park SH, Jang JH, Wistara NJ et al (2018) Anatomical and physical properties of Indonesian bamboos carbonized at different temperatures. J Korean Wood Sci Technol 46:656–669. https://doi.org/10.5658/WOOD.2018.46.6.656

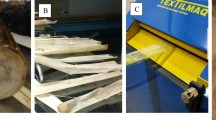

Kar A, Saikia D (2023) Characterization of new natural cellulosic fiber from Calamus tenuis (Jati Bet) cane as a potential reinforcement for polymer composites. Heliyon 9. https://doi.org/10.1016/j.heliyon.2023.e16491

Dampanaboina L, Yuan N, Mendu V (2021) Estimation of crystalline cellulose content of plant biomass using the Updegraff method. J Vis Exp. https://doi.org/10.3791/62031

Agu CV, Njoku OU, Chilaka FC, Agbiogwu D, Iloabuchi KV, Ukazu B (2014) Physicochemical properties of lignocellulosic biofibres from South Eastern Nigeria: their suitability for biocomposite technology. Afr J Biotechnol 13:2050–2057. https://doi.org/10.5897/AJB2013.13443

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794. https://doi.org/10.1177/004051755902901003

Farrukh MA, Butt KM, Chong K-K, Chang WS (2019) Photoluminescence emission behavior on the reduced band gap of Fe doping in CeO2-SiO2 nanocomposite and photophysical properties. J Saudi Chem Soc 23:561–575. https://doi.org/10.1016/j.jscs.2018.10.002

Ding L, Han X, Cao L et al (2022) Characterization of natural fiber from manau rattan (Calamus manan) as a potential reinforcement for polymer-based composites. J Bioresour Bioprod 7:190–200. https://doi.org/10.1016/j.jobab.2021.11.002

Balaji AN, Nagarajan KJ (2017) Characterization of alkali treated and untreated new cellulosic fiber from Saharan aloe vera cactus leaves. Carbohydr Polym 174:200–208. https://doi.org/10.1016/j.carbpol.2017.06.065

Madhu P, Sanjay MR, Jawaid M et al (2020) A new study on effect of various chemical treatments on Agave americana fiber for composite reinforcement: Physico-chemical, thermal, mechanical and morphological properties. Polym Test 85:106437. https://doi.org/10.1016/j.polymertesting.2020.106437

Ganapathy T, Sathiskumar R, Senthamaraikannan P et al (2019) Characterization of raw and alkali treated new natural cellulosic fibres extracted from the aerial roots of banyan tree. Int J Biol Macromol 138:573–581. https://doi.org/10.1016/j.ijbiomac.2019.07.136

Babu BG, Princewinston D, Saravanakumar SS et al (2022) Investigation on the physicochemical and mechanical properties of novel alkali-treated Phaseolus vulgaris fibers. J Nat Fibers 19:770–781. https://doi.org/10.1080/15440478.2020.1761930

Pokhriyal M, Rakesh PK, Rangappa SM, Siengchin S (2023) Effect of alkali treatment on novel natural fiber extracted from Himalayacalamus falconeri culms for polymer composite applications. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-03843-4

Senthamaraikannan P, Saravanakumar SS (2023) Evaluation of characteristic features of untreated and alkali-treated cellulosic plant fibers from Mucuna atropurpurea for polymer composite reinforcement. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-022-03736-y

Herlina Sari N, Wardana ING, Irawan YS, Siswanto E (2018) Characterization of the chemical, physical, and mechanical properties of NaOH-treated natural cellulosic fibers from corn husks. J Nat Fibers 15:545–558. https://doi.org/10.1080/15440478.2017.1349707

Kathirselvam M, Kumaravel A, Arthanarieswaran VP, Saravanakumar SS (2019) Characterization of cellulose fibers in Thespesia populnea barks: influence of alkali treatment. Carbohydr Polym 217:178–189. https://doi.org/10.1016/j.carbpol.2019.04.063

Senthamaraikannan P, Kathiresan M (2018) Characterization of raw and alkali treated new natural cellulosic fiber from Coccinia grandis L. Carbohydr Polym 186:332–343. https://doi.org/10.1016/j.carbpol.2018.01.072

Mudoi MP, Sinha S, Parthasarthy V (2022) Optimizing the alkali treatment of cellulosic Himalayan nettle fibre for reinforcement in polymer composites. Carbohydr Polym 296. https://doi.org/10.1016/j.carbpol.2022.119937

Udhayakumar A, Mayandi K, Nagarajan R et al (2023) Effect of chemical treatment on physico-chemical properties of a novel extracted cellulosic Cryptostegia grandiflora fiber. Mater Res Express. https://doi.org/10.1088/2053-1591/ace29c

Vijay R, Lenin Singaravelu D, Vinod A et al (2019) Characterization of raw and alkali treated new natural cellulosic fibers from Tridax procumbens. Int J Biol Macromol 125:99–108. https://doi.org/10.1016/j.ijbiomac.2018.12.056

Gapsari F, Purnowidodo A, Hidayatullah S, Suteja S (2021) Characterization of Timoho Fiber as a reinforcement in green composite. J Mater Res Technol 13:1305–1315. https://doi.org/10.1016/j.jmrt.2021.05.049

Tengsuthiwat J, Vinod A, Srisuk R et al (2022) Thermo-mechanical characterization of new natural cellulose fiber from Zmioculus zamiifolia. J Polym Environ 30:1391–1406. https://doi.org/10.1007/s10924-021-02284-2

Saravanakumar SS, Kumaravel A, Nagarajan T, Moorthy IG (2014) Effect of chemical treatments on physicochemical properties of Prosopis juliflora fibers. Int J Polym Anal Char 19:383–390. https://doi.org/10.1080/1023666X.2014.903585

Sivasubramanian P, Kalimuthu M, Palaniappan M et al (2021) Effect of alkali treatment on the properties of Acacia caesia bark fibres. Fibers 9. https://doi.org/10.3390/fib9080049

Loganathan TM, Sultan MTH, Ahsan Q et al (2020) Characterization of alkali treated new cellulosic fibre from Cyrtostachys renda. J Mater Res Technol 9:3537–3546. https://doi.org/10.1016/j.jmrt.2020.01.091

Alshammari BA, Alotaibi MD, Alothman OY et al (2019) A new study on characterization and properties of natural fibers obtained from olive tree (Olea europaea L.) residues. J Polym Environ 27:2334–2340. https://doi.org/10.1007/s10924-019-01526-8

Selvaraj M, Pannirselvam N, Ravichandran PT et al (2023) Extraction and characterization of a new natural cellulosic fiber from bark of Ficus carica plant as potential reinforcement for polymer composites. J Nat Fibers 20. https://doi.org/10.1080/15440478.2023.2194699

Johny V, Kuriakose Mani A, Palanisamy S et al (2023) Extraction and physico-chemical characterization of pineapple crown leaf fibers (PCLF). Fibers 11. https://doi.org/10.3390/fib11010005

Sahayaraj AF, Selvan MT, Ramesh M et al (2024) Extraction, purification, and characterization of novel plant fiber from Tabernaemontana divaricate stem to use as reinforcement in polymer composites. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-024-05352-4

Ndazi BS, Karlsson S, Tesha JV, Nyahumwa CW (2007) Chemical and physical modifications of rice husks for use as composite panels. Compos Part A Appl Sci Manuf 38:925–935. https://doi.org/10.1016/j.compositesa.2006.07.004

Seki Y, Sarikanat M, Sever K, Durmuşkahya C (2013) Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos B Eng 44:517–523. https://doi.org/10.1016/j.compositesb.2012.03.013

Tamanna TA, Belal SA, Shibly MAH, Khan AN (2021) Characterization of a new natural fiber extracted from Corypha taliera fruit. Sci Rep 11. https://doi.org/10.1038/s41598-021-87128-8

Indran S, Raj RE (2015) Characterization of new natural cellulosic fiber from Cissus quadrangularis stem. Carbohydr Polym 117:392–399. https://doi.org/10.1016/j.carbpol.2014.09.072

Devnani GL, Sinha S (2019) Extraction, characterization and thermal degradation kinetics with activation energy of untreated and alkali treated Saccharum spontaneum (Kans grass) fiber. Compos B Eng 166:436–445. https://doi.org/10.1016/j.compositesb.2019.02.042

Sahayaraj AF, Selvan MT, Jenish I, Ramesh M (2023) Extraction and characterization of novel cellulosic fiber from Jatropha integerrima plant stem for potential reinforcement in polymer composites. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-04541-x

Gentil Elenga R, Djemia P, Tingaud D, Chauveau T, Goma Maniongui J, Dirras G (2013) Raffia fiber microstructure.

Hadou A, Belaadi A, Alshahrani H, Khan MKA (2024) Extraction and characterization of novel cellulose fibers from Dracaena draco plant. Mater Chem Phys 313:128790. https://doi.org/10.1016/j.matchemphys.2023.128790

Prithiviraj M, Muralikannan R (2022) Investigation of optimal alkali-treated Perotis indica plant fibers on physical, chemical, and morphological properties. J Nat Fibers 19:2730–2743. https://doi.org/10.1080/15440478.2020.1821291

Ramalingam K, Thiagamani SMK, Pulikkalparambil H et al (2023) Novel cellulosic natural fibers from Abelmoschus ficulneus weed: extraction and characterization for potential application in polymer composites. J Polym Environ 31:1323–1334. https://doi.org/10.1007/s10924-022-02687-9

Chen H, Zhang W, Wang X et al (2018) Effect of alkali treatment on wettability and thermal stability of individual bamboo fibers. J Wood Sci 64:398–405. https://doi.org/10.1007/s10086-018-1713-0

Kar A, Saikia D, Palanisamy S et al (2023) Effect of alkali treatment under ambient and heated conditions on the physicochemical, structural, morphological, and thermal properties of Calamus tenuis cane fibers. Fibers 11:92. https://doi.org/10.3390/fib11110092

Selvan MT, Jenish I, Ramesh M, Sahayaraj AF (2023) Characterization of Plumeria pudica bark fiber for reinforcing lightweight polymer composites and evaluating its physical, chemical, and thermal properties. Biomass Convers Biorefin. https://doi.org/10.1007/s13399-023-05172-y

Fiore V, Scalici T, Valenza A (2014) Characterization of a new natural fiber from Arundo donax L. as potential reinforcement of polymer composites. Carbohydr Polym 106:77–83. https://doi.org/10.1016/j.carbpol.2014.02.016

Raia RZ, Iwakiri S, Trianoski R, et al (2021) Effects of alkali treatment on modification of the Pinus fibers. Matéria (Rio de Janeiro) 26. https://doi.org/10.1590/s1517-707620210001.1236

Ramasamy R, Obi Reddy K, Varada Rajulu A (2018) Extraction and characterization of Calotropis gigantea bast fibers as novel reinforcement for composites materials. J Nat Fibers 15:527–538. https://doi.org/10.1080/15440478.2017.1349019

Oushabi A, Sair S, Oudrhiri Hassani F et al (2017) The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): study of the interface of DPF–polyurethane composite. S Afr J Chem Eng 23:116–123. https://doi.org/10.1016/j.sajce.2017.04.005

Han X, Ding L, Tian Z, et al (2021) Extraction and characterization of novel ultrastrong and tough natural cellulosic fiber bundles from manau rattan (Calamus manan). Ind Crops Prod 173. https://doi.org/10.1016/j.indcrop.2021.114103

Li J, Ma R, Lu Y et al (2020) A gravity-driven high-flux catalytic filter prepared using a naturally three-dimensional porous rattan biotemplate decorated with Ag nanoparticles. Green Chem 22:6846–6854. https://doi.org/10.1039/D0GC01709D

Tomlinson PB, Fisher JB, Spangler RE, Richer RA (2001) Stem vascular architecture in the rattan palm Calamus (Arecaceae-Calamoideae-Calaminae). Am J Bot 88:797–809

Kim JM, Song IS, Cho DH, Hong IP (2011) Effect of carbonization temperature and chemical pre-treatment on the thermal change and fiber morphology of kenaf-based carbon fibers. Carbon lett 12:131–137. https://doi.org/10.5714/CL.2011.12.3.131

Verma D, Goh KL (2021) Effect of mercerization/alkali surface treatment of natural fibres and their utilization in polymer composites: mechanical and morphological studies. J Compos Sci 5:175. https://doi.org/10.3390/jcs5070175

Sahayaraj A F, Muthukrishnan M, Jenish I (2023) Extraction and characterization of sponge gourd outer skin fiber. J Nat Fibers 20. https://doi.org/10.1080/15440478.2023.2208888

Wirawan WA, Sabitah A, Choiron MA et al (2023) Effect of chemical treatment on the physical and thermal stabillity of Hibiscus tiliaceus bark fiber (HBF) as reinforcement in composite. Results Eng 18:101101. https://doi.org/10.1016/j.rineng.2023.101101

Saha A, Kumari P (2023) Effect of alkaline treatment on physical, structural, mechanical and thermal properties of Bambusa tulda (Northeast Indian species) based sustainable green composites. Polym Compos 44:2449–2473. https://doi.org/10.1002/pc.27256

Sathishkumar T, Navaneethakrishnan P, Shankar S et al (2013) Characterization of natural fiber and composites – a review. J Reinf Plast Compos 32:1457–1476. https://doi.org/10.1177/0731684413495322

Acknowledgements

We acknowledge CSIR-NEIST in Jorhat, Assam, for granting us access to their chemical analysis facility. Special thanks are extended to SAIC at Tezpur University for their support with FTIR and SEM, to SAIC at IASST Guwahati for providing AFM facilities, and to SAIF at Gauhati University for access to PXRD and TGA facilities. We also extend our appreciation to CSIC at Dibrugarh University for their valuable contribution to EDX analysis. Finally, we acknowledge Mr. Sanjib Sarma at IIT Guwahati for generously allowing us to utilize their laboratory for conducting tensile tests.

Author information

Authors and Affiliations

Contributions

Conceptualization: Dip Saikia; methodology: Arup Kar, Dip Saikia; formal analysis and investigation: Arup Kar, Dip Saikia; writing—original draft preparation: Arup Kar; writing—review and editing: Arup Kar, Dip Saikia, Narayanasamy Pandiarajan; resources: Dip Saikia, Narayanasamy Pandiarajan; supervision: Dip Saikia.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kar, A., Saikia, D. & Pandiarajan, N. Characterization of alkali-treated cellulosic fibers derived from Calamus tenuis canes as a potential reinforcement for polymer composites. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05560-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05560-y