Abstract

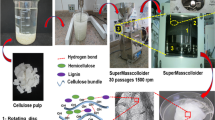

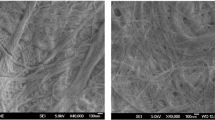

Coating paper with cellulose micro/nanofibrils (CMF/CNF) can improve the performance of paper packaging. However, the cost of the process is high due to the significant energy consumption during the CMF/CNF production process, which can be reduced through pre-treatment of cellulosic fibers. The objective of this work was, therefore, to evaluate the performance of CMF/CNF subjected to accelerated carbonation with different concentrations of calcium hydroxide (5% and 10% m/m) as a paper coating for packaging production in terms of spreading properties of adhesives, air permeability, and water absorption. The CMF/CNF coating was able to fill pores contained in the papers, with the treatment with 10% carbonation (CMF/CNF 10%) being the one that adhered best to the surface. There was a reduction in surface roughness from 1.35 ± 0.53 μm (uncoated paper) to 0.72 ± 0.21 μm (CMF/CNF 10%). Similarly, air permeability in the coated treatments was decreased, indicating good barrier properties and possible CO2 absorption activity in the carbonated samples. Coated papers showed greater spreading of water, PVA, and PVOH. On the other hand, the Cobb value dropped from 41.55 ± 3.83 g m2 (uncoated paper) to 26.26 ± 2.36 g m2 (CMF/CNF 10%). CMF/CNF subjected to pre-treatment with accelerated carbonation have the potential for use as a coating material, being recommended for applications in food packaging and those that will be subjected to gluing/coating processes with other materials.

Similar content being viewed by others

Data availability

No datasets were generated or analysed during the current study.

References

Abdelouahab NB, Gossard A, Ma X, Dialla H, Maillet B, Rodts S, Coussot P (2021) Understanding mechanisms of drying of a cellulose slurry by magnetic resonance imaging. Cellulose 28:5321–5334. https://doi.org/10.1007/s10570-021-03916-5

Ahankari SS, Subhedar AR, Bhadauria SS, Dufresne A (2021) Nanocellulose in food packaging: a review. Carbohydr Polym 255. https://doi.org/10.1016/j.carbpol.2020.117479

Antón N, González-Fernandez A, Villarino A (2020) Reliability and mechanical properties of materials recycled from multilayer flexible packages. Materials 13:3992. https://doi.org/10.3390/ma13183992

Anukiruthika T, Sethupathy P, Wilson A, Kashampur K, Moses JA, Anandharamakrishnan C (2020) Multilayer packaging: advances in preparation techniques and emerging food applications. Compr Rev Food Sci Food Saf 19:1156–1186. https://doi.org/10.1111/1541-4337.12556

Arantes LS, Mascarenhas ARP, Scatolino MV, Tonoli GHD, Mendes LM, Borges IO, Guimarães Júnior JB (2023) Pre-treatment with calcium hydroxide and accelerated carbonation for cellulosic pulp fibrillation. Nordic Pulp Paper Res J 1–16. https://doi.org/10.1515/npprj-2022-0101

Ariffin MNFN, Yasim-Anuar TAT, Ghaemi F, Hassan MA, Ibrahim NA, Ngee JLH, Yunus WMZ (2018) Superheated steam pretreatment of cellulose affects its electrospinnability for microfibrillated cellulose production. Cellulose 25:3853–3859. https://doi.org/10.1007/s10570-018-1859-3

Assis CA, Iglesias MC, Bilodeau MA, Johnson D (2018) Cellulose micro-and nanofibrils (CMNF) manufacturing-financial and risk assessment. Biofuels Bioprod Biorefining 12:2:251–264. https://doi.org/10.1002/bbb.1835

ASTM Standard (2005) ASTM D-3285-93, Standard Test Method for Water Absorptiveness of Nonbibulous Paper and Paperboard. Cobb Test

Azeredo HMC, Rosa MF, Mattoso LHC (2017) Nanocellulose in bio-based food packaging applications. Ind Crops Prod 97:664–671. https://doi.org/10.1016/j.indcrop.2016.03.013

Banvillet G, Depres G, Belgacem N, Bras J (2021) Alkaline treatment combined with enzymatic hydrolysis for efficient celulose nanofibrilas production. Carbohydr Polym 255. https://doi.org/10.1016/j.carbpol.2020.117383

Basumatary IB, Mukherjee A, Katiyar V, Kumar S (2020) Biopolymer-based nanocomposite films and coatings: recent advances in shelf-life, improvement of fruits and vegetables. Crit Rev Food Sci Nutr 1–24. https://doi.org/10.1080/10408398.2020.1848789

Besbes I, Vilar S, Boufi S (2011) Nanofibrillation cellulose from TEMPO-oxidized eucalyptus fibres: Effect of the carboxyl content. Carbohydr Polym 84:975–983. https://doi.org/10.1016/j.carbpol.2010.12.052

Cruz TM, Mascarenhas ARP, Scatolino MV, Faria DL, Matos LC, Duarte PJ, Moreira Neto J, Mendes LM, Tonoli GHD (2022) Hybrid films from plant and bacterial nanocellulose: mechanical and barrier properties. Nord Pulp Pap Res J 37:159–174. https://orcid.org/0000-0001-6623-5310

Dey A, Kayal N, Chakrabarti O, Caldato RF, Innocentini MDM, Guerra VG (2014) Investigations on material and mechanical properties, air-permeation behavior and filtration performance of mullite-bonded porous SiC ceramics. Int J Appl Ceram Technol 11:5:804–816. https://doi.org/10.1111/ijac.12090

Drelich JW (2019) Contact angles: from mistakes to new developments through liquidsolid adhesion measurements. Adv Colloid Interface Sci 267:1–14. https://doi.org/10.1016/j.cis.2019.02.002

Galina NR, Arce GLAF, Ávila I (2019) Evolution of carbon capture and storage by mineral carbonation: data analysis and relevance of the theme. https://doi.org/10.1016/j.mineng.2019.105879

Gok B, Akpinar D (2020) Investigation of strength and migration of corrugated cardboard boxes. Hittite J Sci Eng 7:163–168. https://doi.org/10.17350/HJSE19030000185

Huang JY, Li X, Zhou W (2015) Safety assessment of nanocomposite for food packaging application. Trends Food Sci Technol 45:2:187–199. https://doi.org/10.1016/j.tifs.2015.07.002

Inamochi T, Funahashi R, Nakamura Y, Saito T (2017) Effect of coexisting salto on TEMPO-mediated oxidation of wood celulose for preparation of nanocellulose. Cellulose 24:9:4097–4101. https://doi.org/10.1007/s10570-017-1402-y

Innocentini MDM, Sepulveda P, Ortega F (2005) Permeability, Chap. 4.2 in The book: Cellular Ceramics: Structure, Manufacturing, Properties and Applications, Michael Scheffler, Paolo Colombo (Editor), ISBN: 3-527-31320-6. https://doi.org/10.1002/3527606696.ch4b

Innocentini MDM, Chacon WS, Caldato RF, Paula GR, Adabo GL (2015) Microstructural, physical, and fluid dynamic assessment of spinel-based and phosphate-bonded investments for dental applications. Int J Appl Ceram Technol 12:306–318. https://doi.org/10.1111/ijac.12194

Ishiguro M, Endo T (2015) Effect of the addition of calcium hydroxide on the hydrothermal-mechanochemical treatment of Eucalyptus. Bioresour Technol 177:298–301. https://doi.org/10.1016/j.biortech.2014.10.135

Jin K, Tang Y, Liu J, Wang J, Ye C (2021) Nanofibrillated cellulose as coating agent for food packaging paper. Int J Biol Macromol 168:331–338. https://doi.org/10.1016/j.ijbiomac.2020.12.066

Kaldéus T, Larsson PT, Boujemaoui A, Malmstrom E (2018) One-pot preparation of bi-funcional celulose nanofibrilas. Cellulose 25:12:7031–7042. https://doi.org/10.1007/s10570-018-2066-y

Karim Z, Afrin S, Husain Q, Danish R (2017) Necessity of enzymatic hydrolysis for production and functionalization of nanocelluloses. Crit Rev Biotechnol 37:3:355–370. https://doi.org/10.3109/07388551.2016.1163322

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose – its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:2:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Mascarenhas ARP, Scatolino MV, Santos AA, Norcino LB, Duarte PJ, Melo RR, Dias MC, Faria CET, Mendonça MC, Tonoli GHD (2022a) Hydroxypropyl methylcellulose films reinforced with cellulose micro/nanofibrils: study of physical, optical, surface, barrier and mechanical properties. Nord Pulp Pap Res J 1–19. https://doi.org/10.1515/npprj-2022-0006

Mascarenhas ARP, Scatolino MV, Dias MC, Martins MA, Melo RR, Mendonça MC, Tonoli GHD (2022b) Association of cellulose micro/nanofibrils and silicates for cardboard coating: Technological aspects for packaging. Ind Crops Prod 188:115667. https://doi.org/10.1016/j.indcrop.2022.115667

Morais FP, Carta AMMS, Amaral ME, Curto JMR (2021) Micro/nano-fibrillated cellulose (MFC/NFC) fibers as an additive to maximize eucalyptus fibers on tissue paper production. Cellulose 28:6587–6605. https://doi.org/10.1007/s10570-021-03912-9

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. Bioresour Technol 96:673–686. https://doi.org/10.1016/j.biortech.2004.06.025

Necas D, Klapetek P (2012) Gwyddion: an open-source software for SPM data analysis. Open Phys 10:181–188

Nechita P, Roman M (2020) Review on polysaccharides used in coatings for food packaging papers. Coatings 10:566. https://doi.org/10.3390/coatings10060566

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25. https://doi.org/10.1016/j.indcrop.2016.02.016

Rol F, Belgacem MN, Gandini A, Bras J (2018) Recent advances in surface-modified celulose nanofibrilas. Prog Polym Sci 88:241–264. https://doi.org/10.1016/j.progpolymsci.2018.09.002

Rol F, Sillard C, Bardet M, Yarava JR, Emsley L, Gablin C, Léonard D, Belgacem N, Bras J (2020) Cellulose phosphorylation comparison and analysis of phosphorate position on celulose fibers. Carbohydr Polym 229:115294. https://doi.org/10.1016/j.carbpol.2019.115294

Rueden CT, Schindelin J, Hiner MC, Dezonia BE, Walter AE, Arena ET, Eliceiri KW (2017) ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinformatics 18:529. https://doi.org/10.1186/s12859-017-1934-z

Santos AA, Matos LC, Mendonça MC, Lago RC, Muguet MCS, Damásio RAP, Ponzecchi A, Soares JR, Sanadi AR, Tonoli GHD (2023) Evaluation of paper coated with cationic starch and carnauba wax mixtures regarding barrier properties. Industrial Crops Prod 203:117177. https://doi.org/10.1016/j.indcrop.2023.117177

Silva LCE, Cassago A, Batirrola LC, Gonçalves MC, Portugal RV (2020) Specimen preparation optimization for size and morphology characterization of nanocellulose by TEM. Cellulose 27:5435–5444. https://doi.org/10.1007/s10570-020-03116-7

Sönmez S, Özden O (2018) Barrier Properties of Paper and Cardboard. In: SALMAN, S. Academic Researches in Architecture, Engineering Planning and Design. İskitler: Gece Kitaplığı 171–183

TAPPI (1994) T 458 cm-94, Surface wettability of paper (angle of contact method)

Vaezi K, Asadpour G, Sharifi SH (2019) Effect of coating with novel bio nanocomposites of cationic starch/cellulose nanocrystals on the fundamental properties of the packaging paper. Polym Test 80:106080. https://doi.org/10.1016/j.polymertesting.2019.106080

Yenidogan S (2020) Nanocrystalline cellulose and polyvinyl alcohol coating application to cardboard packaging papers and investigation of the effects on paper properties. Mater Sci 26:3:317–322. https://doi.org/10.5755/j01.ms.26.3.21499

Acknowledgements

The authors would like to thank the Postgraduate Program in Biomaterials Engineering at the Federal University of Lavras (UFLA), the National Council for Scientific and Technological Development (CNPq) and the Minas Gerais Research Support Foundation (FAPEMIG).

Author information

Authors and Affiliations

Contributions

Lorran de Sousa Arantes: Investigation, Visualization, Data presentation, Writing – original draft. Adriano Reis Prazeres Mascarenhas: Investigation, Visualization, Data presentation, Writing – original draft. Ianca Oliveira Borges: Visualization, Data presentation, Investigation, Writing – original writing. Rafael Carvalho do Lago: Visualization, Data presentation, Research, Writing – original draft. Carlos Henrique da Silva: Visualization, Data presentation, Investigation, Writing – original draft. Murilo Daniel de Mello Innocentini: Conceptualization, Visualization, Data presentation, Writing – review and editing. Lourival Marin Mendes: Resources, Project Administration, Fundraising, Supervision. Gustavo Henrique Denzin Tonoli: Resources, Project administration, Fundraising, Supervision.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

The authors’ participation was authorized during the construction of the study.

Consent for publication

All authors agree with the publication of the article in this journal.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sousa Arantes, L.d., Mascarenhas, A.R.P., Borges, I.O. et al. Use of carbonated cellulose micro/nanofibrils in the coating of sack kraft paper. Eur. J. Wood Prod. (2024). https://doi.org/10.1007/s00107-024-02068-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00107-024-02068-0