Abstract

Distillery spentwash from molasses-based alcohol distilleries poses a significant challenge to the Indian distilleries and the environment. Generating energy, utilizing it as fertilizer in agriculture, and using it as a growth medium for algal production are potential methods for recovering resource from the spentwash. This study primarily focuses on achieving a circular bioeconomy in the treatment and disposal of distillery spentwash. The term circular-bioeconomy underscores the integration of biological processes into the circular economy framework. In this context, the study contributes to the circular economy by not only addressing the challenge of distillery spentwash but also by incorporating biomethanation and recycling of biomethanated distillery spentwash (BDS) as organic fertilizer in agriculture, as well as algal biomass production in BDS. Biomethanation was performed at different hydraulic retention times (HRTs) using upflow anaerobic sludge blanket (UASB) reactor; a HRT of 6 days was optimum. Based on laboratory findings, full-scale UASB reactors were operated for 6 days HRT. Throughout the study period, reactors operations remained stable, with 63.09 to 65.61%, 72.59 to 77.31%, and 58.39 to 60.02% reductions in chemical oxygen demand (COD), biochemical oxygen demand (BOD), and total solids (TS), respectively, at an organic loading rate (OLR) of 2.40 to 4.52 kg COD m−3 day−1. Field experiments with groundnut and sugarcane demonstrated that BDS could serve as a valuable source of plant nutrients, sustaining crop yields, soil productivity, and soil health without polluting the soil and ground water. The use of a growth medium comprising BDS is a cost-effective alternative for treating distillery spentwash and simultaneously producing Spirulina sp. on a large scale.

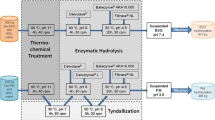

Graphical Abstract

Similar content being viewed by others

Data availability

The raw data of this paper are available at the University Library, Tamil Nadu Agricultural Univversity, Coimbatore, India.

Abbreviations

- APHA:

-

American Public Health Association

- BDS:

-

Biomethanated distillery spentwash

- BOD5 :

-

Biochemical oxygen demand

- CPCB:

-

Central Pollution Control Board

- COD:

-

Chemical oxygen demand

- DO:

-

Dissolved oxygen

- EC:

-

Electrical conductivity

- ETP:

-

Effluent treatment plant

- GLS:

-

Gas–liquid-solid

- GHG:

-

Greenhouse gas

- HRT:

-

Hydraulic retention time

- MoEF&CC:

-

Ministry of Environment, Forestry, and Climate Change

- N:

-

Nitrogen

- OD:

-

Optical density

- OLR:

-

Organic loading rate

- RSC:

-

Residual sodium carbonate

- SAR:

-

Sodium adsorption ratio

- SSP:

-

Soluble sodium percentage

- TDS:

-

Total dissolved solids

- TS:

-

Total solids

- TSS:

-

Total suspended solids

- UAHR:

-

Upflow anaerobic hybrid reactor

- UASB:

-

Upflow anaerobic sludge blanket

- VSS:

-

Volatile suspended solids

- ZLD:

-

Zero liquid discharge

References

Singh P, Srivastava N, Singh P (2018) Treatment of distillery waste water by continuous electrocoagulation process. Int J Environ Resour 7:413–418

Selvamurugan M, Doraisamy P, Maheswari M (2011) Effect of biomethanated distillery spentwash and pressmud biocompost on microbial and enzyme dynamics in sugarcane grown soil. J Biol Sci 11:417–422

Yashpal, S (2020) Distillery spent wash and its utilisation in agriculture. Publisher: The Wealthy Waste School India. Lucknow, India. pp 1–360. https://www.wealthywaste.com/wp-content/uploads/2022/07/DISTILLERY-SPENT-WASH-AND-ITS-UTILISATION-IN-AGRICULTURE-converted.pdf. Accessed 12 Jan 2024

Paul Sebastian S, Kalaiselvi P, Suganya K, Kavitha R, Selvamurugan M, Poornima R, Bush R, Salom GT, Palanisami T (2022) Novel resources recovery from anaerobic digestates: current trends and future perspectives. Crit Rev Environ Sci Technol 52:1915–1999

Kamble SM, Kumar M, Dasar Gopal V, Gundlur SS (2017) Distillery spent wash production, treatment and utilisation in agriculture –a review. Int J Pure Appl Bio Sci 5(2):379–389

Nagarajan S, Ranade VV (2020) Pre-treatment of distillery spent wash (vinasse) with vortex based cavitation and its influence on biogas generation. Biores Technol Reports 11:100480. https://doi.org/10.1016/j.biteb.2020.100480

Barbosa MYU, Alves I, Nery VD, Sakamoto IK, Pozzi E, Damianovic MHRZ (2022) Methane production in a UASB reactor from sugarcane vinasse: shutdown or exchanging substrate for molasses during the off-season? J Water Proc Eng 47:102664. https://doi.org/10.1016/j.jwpe.2022.102664

Ahammad SZ, Sreekrishnan TR (2016) Energy from wastewater treatment. In: Prasad MNV (ed) Bioremediation and bioeconomy. Elsevier, pp 523–536

Daud MK, Rizvi H, Akram MF, Ali S, Rizwan M, Nafees M, Jin ZS (2018) Review of upflow anaerobic sludge blanket reactor technology: effect of different parameters and developments for domestic wastewater treatment. J Chem 13. https://doi.org/10.1155/2018/1596319

Mainardis M, Buttazzoni M, Goi D (2020) Up-flow anaerobic sludge blanket (UASB) technology for energy recovery: a review on state-of-the-art and recent technological advances. Bioengineering (Basel) 7:43

Dutta A, Davies C, Ikumi DS (2018) Performance of upflow anaerobic sludge blanket (UASB) reactor and other anaerobic reactor configurations for wastewater treatment: a comparative review and critical updates. J Water Sup Res Tech Aqua 67:858–884

Mahimairaja S, Bolan NS (2004) Problems and prospects of agricultural use of distillery spentwash in India. Poster Paper in Symposium 7: Managing disposal of waste and waste water on land. Opportunities and challenges. 3rd Australian New Zealand Soils Conference, University of Sydney, Australia, Super soil the Regional Institute Limited. Published on CDROM, 5–9 December.

Umair Hassan M, Aamer M, Umer Chattha M, Haiying T, Khan I, Seleiman MF, Rasheed A, Nawaz M, Rehman A, Talha Aslam M, Afzal A, Huang G (2021) Sugarcane distillery spent wash (DSW) as a bio-nutrient supplement: a win-win option for sustainable crop production. Agronomy 11:183

Kaushik R, Prasanna R, Joshi HC (2006) Utilization of anaerobically digested distillery effluent for the production of Spirulina platensis (ARM 730). J Sci Ind Res 65:521–525

Sankaran K, Premalatha M, Vijayasekaran M, Somasundaram VT (2014) DEPHY project: distillery wastewater treatment through anaerobic digestion and phycoremediation—a green industrial approach. Renew Sustain Ener Rev 37:634–643

Baird R, Bridgewater L (2017) Standard methods for the examination of water and wastewater. 23rd edn. Washington, D.C., American Public Health Association

Aniyikaiye TE, Oluseyi T, Odiyo JO, Edokpayi JN (2019) Physico-chemical analysis of wastewater discharge from selected paint industries in Lagos, Nigeria. Int J Environ Res Public Health 16(7):1235

Ademoroti CMA (1996) Standard methods for water and effluents analysis. 1st edn. Foludex Press Ltd., Ibadan, Nigeria, pp 40–103

Piper CS (1966) Soil and plant analysis. Inter Science Publication Incorporated, NewYork

Jackson ML (1973) Soil chemical analysis. Prentice Hall of India. Pvt. Ltd., NewDelhi

Lettinga G (2001) Digestion and degradation, air for life. Water Sci Technol 44:157–176

Central Pollution Control Board CPCB (2005) Protocol for one-time controlled land application of treated post bio-methanated distillery spentwash as liquid manure. Ministry of Environment and Forest, Government of India

Mac Kinney G (1941) Absorption of light by chlorophyll solutions. J Biol Chem 140:315–322

Lowry OH, Rosebrough NJ, Farr AL, Randall RJ (1951) Protein measurement with the Folin phenol reagent. J Biol Chem 193:265–275

Hassid WZ, Abraham S (1957) Chemical procedures for analysis of polysaccharides. I. Determination of glycogen and starch - determination of glycogen with the anthrone reagent. Methods Enzymol 3:35–36

Baskar M, Kayalvizhi C, Bose MSC (2003) Eco-friendly utilisation of distillery effluent in agriculture–A review. Agricultural Reviews 24(1):16–30

Mohana S, Acharya BK, Madamwar D (2009) Distillery spent wash: treatment technologies and potential applications. J Hazard Mater 163:12–25

Lettinga G (1995) Anaerobic digestion and wastewater treatment systems. Antoine Leeuwenhoek 67:3–28

Jetty A, Krishna Prasad K, Venkata Naidu G, Gangani Rao A (2004) Enumeration of anaerobic bacteria from upflow anaerobic sludge blanket (UASB) reactor for the treatment of chemical industry waste water. Asian J Microbiol Biotech Env Sci 6(2):253–258

Selvamurugan M, Doraisamy P, Maheswari M (2014) High-rate anaerobic treatment of distillery spentwash using UASB and UAHR. Int J Environ Eng 6(3):273–286

Ladu JLC, Lu X (2014) Effects of hydraulic retention time, temperature, and effluent recycling on efficiency of anaerobic filter in treating rural domestic wastewater. Water Sci Eng 7(2):168–182

Acharya BK, Mohana S, Madamwar D (2008) Anaerobic treatment of distillery spentwash: a study on upflow anaerobic fixed film bioreactor. Biores Technol 99:462–4626

Musa MA, Idrus S (2020) Effect of hydraulic retention time on the treatment of real cattle slaughterhouse wastewater and biogas production from HUASB reactor. Water 12:490

de Barros VG, Duda RM, de Oliveira RA (2016) Biomethane production from vinasse in upflow anaerobic sludge blanket reactors ınoculated with granular sludge. Braz J Microbiol 47:628–639

Souza ME, Fuzaro G, Polegato AR (1992) Thermophilic anaerobic digestion of vinasse in pilot plant UASB reactor. Water Sci Technol 25(7):213–222

Yamaguchi T, Yamazaki S, Uemura S, Tseng IC, Ohashi A, Harada H (2001) Microbial-ecological significance of sulfide precipitation within anaerobic granular sludge revealed by micro-electrodes study. Water Res 35(14):3411–3417

Cunha JR, Tervahauta T, van der Weijden RD, Temmink H, Leal LH, Zeeman G, Buisman CJN (2018) Environ Sci Technol 52(22):13144–13154

Kalyazhnyi SV, Gladchenko MA, Sklyar VI, Kizimenko YS, Shcherbakov SS (2001) One and two-stage upflow anaerobic sludge-bed reactor pretreatment of winery wastewater. Biotechnol Appl Biochem 90:107–124

Doraisamy P, Nandakumar NB, Maheswari M, Selvamurugan M (2013) Comparative performance of anaerobic reactors for treatment of sago industry wastewater. Clean Technol Environ Pol 2:391–394

Pererva Y, Miller CD, Sims RC (2020) Approaches in design of laboratory-scale UASB reactors. Processes 8:734. https://doi.org/10.3390/pr8060734

Chinnaraj S, Venkoba Rao G (2006) Implementation of an UASB anaerobic digester at bagasse-based pulp and paper industry. Biomass Bioenergy 30:273–277

Arthur PMA, Konaté Y, Sawadogo B, Sagoe G, Dwumfour-Asare B, Ahmed I, Williams MNV (2022) Performance evaluation of a full-scale up flow anaerobic sludge blanket reactor coupled with trickling filters for municipal wastewater treatment in a developing country. Heliyon 8:13

Cerri CL, Polo A, Reuz F, Lubo MC, Eduardo BP (1988) Organic residue of the cane agro-industry I. Physical and chemical characteristics. Int Sugarcane J 92:105A

Kachot NA, Malvia DD, Solanki RM, Sagarka BK (2001) Integrated nutrient management in rainy season groundnut (Arachis hypogaea). Indian J Agron 46:516–522

Hao X, Chang C (2002) Effect of 25 annual cattle manure applications on soluble and exchangeable cation in soil. Soil Sci 167:126–134

Naveed S, Rehim A, Imran M, Bashir MA, Anwar MF, Ahmad F (2018) Organic manures: an efficient move towards maize grain biofortification. Int J Rec Org Waste Agric 7:1–9

De Souza SAV (2007) Use of Agrochemicals. In: Sugar cane's energy: Twelve studies on Brazilian Sugar Cane agribusiness and its sustainability. Editors: Macedo C, Sao Paulo Sugar Cane Agro industry Union, Publ.: UNICA Bertendies Editoves Llda, Sao Parilo, Brazil, pp 163–175

Srivastava S, Chopra AK, Pathak C (2012) Ferti-irrigational impact of distillery effluent and Di-ammonium phosphate on the soil and growth characteristics of egg plant (Solanum melongena L.). J Applied and Natural Sciences 4:275–283

Valliappan K (1998) Recycling of distillery spentwash- an ecofriendly effective reclamation technology for sodic soils. Ph.D. Thesis, Tamil Nadu Agricultural University, Coimbatore, India

Kayalvizhi C, Gopal H, Baskar M, Sheik Dawood M, Bose MSC, Rajukkannu K (2001) Effect of fertigation with distillery effluent on soil properties and yield of sugarcane. In: National seminar on use of poor quality water and sugar industrial effluents in agriculture, ADAC & RI (TNAU), Tiruchirapalli, p 84

Cruz RL, Righetto AM, Nogueiro MA (1991) Experimental investigation of soil and ground water impacts caused by vinasse disposal. Wat Sci Technol 24(11):77–85

Chandraju S, Chidankumar CS, Venkatachalapathy R (2011) Studies on the impact of distillery spentwash irrigation on the yields of tuber/root medicinal plants in normal and spentwash treated soil. Res J Agric Sci 2:255–257

Bhadoria PBS, Prakash YS, Kar S, Rakshit A (2003) Relative efficacy of organic manures on rice production in lateritic soil. Soil Use Manag 19:80–82

Liang YC, Sun WC, Zhu YG, Christie P (2007) Mechanisms of silicon-mediated alleviation of abiotic stresses in higher plants, a review. Environ Pollut 147:422–428

Allred BJ, Brown GO, Bigham JM (2007) Nitrate mobility under unsaturated flow conditions in four initially dry soils. Soil Sci 172:27–41

Muhammad TM, Muhammad YK, Mushtaq AB, Taj MJ (2012) Effects of spent wash of ethanol industry on groundwater: a case study of Rahimyar Khan district. Pakistan J Environ Sci Water Resour 4:85–94

Lowrey J, Brooks MS, McGinn PJ (2015) Heterotrophic and mixotrophic cultivation of microalgae for biodiesel production in agricultural wastewaters and associated challenges-a critical review. J Appl Phycol 27:1485–1498

Chojnacka K, Noworyta A (2004) Evaluation of Spirulina sp. growth in photoautotrophic, heterotrophic and mixotrophic cultures. Enz Microgr Technol 34:461–465

Islam MR, Habib MAB, Miah MI, Khan ANMAI (2004) Growth performance and organic nutrients of chlorella ellipsoidea grown in cabbage powder media. J Asiat Soc Bangladesh Sci 30:71–78

Ravikumar Y, Razack SA, Yun J, Zhang G, Zabed HM, Qi X (2021) Recent advances in microalgae-based distillery wastewater treatment. Environ Technol Innov 24:101839

Funding

M/s. Bhavani Distilleries and Chemicals Limited, India, have provided financial support to carry the project on “High-rate biomethanation and eco-friendly utilization of spentwash.”

Role of funding source

Mr. K. Eswaran, Administrative Manager, M/s. Bhavani Distilleries and Chemicals Limited have rendered timely help during survey and sample collection.

Author information

Authors and Affiliations

Contributions

M. Selvamurugan—investigation, original draft and conceptualization.

P. Doraisamy—project administration, supervision, reviewing and editing.

M. Maheswari—supervision, reviewing and editing.

K.Valliappan—reviewing and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Selvamurugan, M., Doraisamy, P., Maheswari, M. et al. An integrated approach to achieve a circular bioeconomy in the treatment and disposal of distillery spentwash. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05581-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05581-7