Abstract

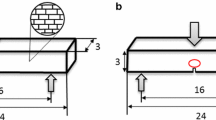

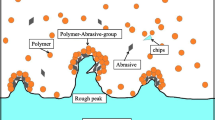

It is generally considered that heat treatments have a negative impact on the mechanical properties of nacre due to thermal decomposition of the organic matrix. However, the present work investigated the microindentation behavior on fresh and heat-treated nacres from two orthogonal directions, and the results demonstrate that both hardness value and damage tolerance can remain almost unchanged on the cross-section with the organic matrix degeneration, despite a significant deterioration on the platelet surface. Theoretical analyses suggest that the anisotropic response of indentation behavior to heat treatment in nacre is primarily caused by its structural orientation. Specifically, compared with a single layer of irregular interplatelet interfaces in cross-sectional specimens, the multiple layers of parallel interlamellar interfaces in in-plane specimens exhibit a much greater ability to impede indenter-triggered destruction, and heat treatments would reduce the in-plane hardness but nearly have no effect on the cross-sectional hardness. Moreover, the deeper embedding of platelets in cross-sectional specimens enhances their resistance to interface cracking caused by organic matrix degradation at high temperatures, leading to a reduced sensitivity to damage. Therefore, the indentation behavior of nacre shows different tendencies in response to variations in the organic matrix state along normal and parallel directions.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Lossada, F., Abbasoglu, T., Jiao, D., Hoenders, D., & Walther, A. (2020). Glass transition temperature regulates mechanical performance in nacre-mimetic nanocomposites. Macromolecular Rapid Communications, 41, 2000380. https://doi.org/10.1002/marc.202000380.

Ji, H. M., Qi, Q. J., Liang, S. M., Yu, H., & Li, X. W. (2022). Ordered stereom structure in sea urchin tubercles: High capability for energy dissipation. Acta Biomaterialia, 150, 310–323. https://doi.org/10.1016/j.actbio.2022.07.031.

Dai, H., Dai, W., Hu, Z., Zhang, W., Zhang, G., & Guo, R. (2023). Advanced composites inspired by biological structures and functions in nature: Architecture design, strengthening mechanisms, and mechanical-functional responses. Advanced Science, 10, 2207192. https://doi.org/10.1002/advs.202207192.

Nepal, D., Kang, S., Adstedt, K. M., Kanhaiya, K., Bockstaller, M. R., Catherine Brinson, L., Buehler, M. J., Coveney, P. V., Dayal, K., El-Awady, J. A., Henderson, L. C., Kaplan, D. L., Keten, S., Kotov, N. A., Schatz, G. C., Vignolini, S., Vollrath, F., Wang, Y., Yakobson, B. I., … Heinz, H. (2023). Hierarchically structured bioinspired nanocomposites. Nature Materials, 22, 18–35. https://doi.org/10.1038/s41563-022-01384-1

Peng, X., Zhang, B., Wang, Z., Su, W., Niu, S., Han, Z., & Ren, L. (2022). Bioinspired strategies for excellent mechanical properties of composites. Journal of Bionic Engineering, 19, 1203–1228. https://doi.org/10.1007/s42235-022-00199-9.

Gao, W., Wang, M., & Bai, H. (2020). A review of multifunctional nacre-mimetic materials based on bidirectional freeze casting. Journal of the Mechanical Behavior of Biomedical Materials, 109, 103820. https://doi.org/10.1016/j.jmbbm.2020.103820.

Chen, Q., Ma, Z., Wang, M., Wang, Z., Feng, J., Chevali, V., & Song, P. (2023). Recent advances in nacre-inspired anisotropic thermally conductive polymeric nanocomposites. Nano Research, 16, 1362–1386. https://doi.org/10.1007/s12274-022-4824-2.

Liang, S. M., Ji, H. M., & Li, X. W. (2021). A high-strength and high-toughness nacreous structure in a deep-sea Nautilus shell: Critical role of platelet geometry and organic matrix. Journal of Materials Science & Technology, 88, 189–202. https://doi.org/10.1016/j.jmst.2021.01.082.

Woigk, W., Poloni, E., Grossman, M., Bouville, F., Masania, K., & Studart, A. R. (2022). Nacre-like composites with superior specific damping performance. PNAS, 119, e2118868119. https://doi.org/10.1073/pnas.2118868119

Zhang, Z., Zhu, J., Chu, Y., Chen, Z., Guo, S., & Xu, J. (2019). Correlation between microstructure and failure mechanism of Hyriopsis cumingii shell structure. Journal of Bionic Engineering, 16, 869–881. https://doi.org/10.1007/s42235-019-0102-8.

Barthelat, F., Tang, H., Zavattieri, P. D., Li, C. M., & Espinosa, H. D. (2007). On the mechanics of mother-of-pearl: A key feature in the material hierarchical structure. Journal of the Mechanics and Physics of Solids, 55, 306–337. https://doi.org/10.1016/j.jmps.2006.07.007.

Chen, P. Y., Lin, A. Y. M., Lin, Y. S., Seki, Y., Stokes, A. G., Peyras, J., Olevsky, E. A., Meyers, M. A., & McKittrick, J. (2008). Structure and mechanical properties of selected biological materials. Journal of the Mechanical Behavior of Biomedical Materials, 1, 208–226. https://doi.org/10.1016/j.jmbbm.2008.02.003.

Ji, H. M., Li, X. W., & Chen, D. L. (2022). An artful microstructure in nacre: Superior resistance to fatigue deformation. International Journal of Fatigue, 157, 106705. https://doi.org/10.1016/j.ijfatigue.2021.106705.

Liang, S. M., Ji, H. M., & Li, X. W. (2020). Thickness-dependent mechanical properties of nacre in Cristaria plicata shell: Critical role of interfaces. Journal of Materials Science & Technology, 44, 1–8. https://doi.org/10.1016/j.jmst.2019.10.039.

Meng, Y. F., Zhu, Y. B., Zhou, L. C., Meng, X. S., Yang, Y. L., Zhao, R., Xia, J., Yang, B., Lu, Y. J., Wu, H. A., Mao, L. B., & Yu, S. H. (2022). Artificial nacre with high toughness amplification factor: Residual stress-engineering sparks enhanced extrinsic toughening mechanisms. Advanced Materials, 34, 2108267. https://doi.org/10.1002/adma.202108267.

Jackson, A. P., Vincent, J. F. V., & Turner, R. M. (1988). The mechanical design of nacre. Proceedings of the Royal Society London B, 234, 415–440. https://doi.org/10.1098/rspb.1988.0056.

Sumitomo, T., Kakisawa, H., Owaki, Y., & Kagawa, Y. (2008). In situ transmission electron microscopy observation of reversible deformation in nacre organic matrix. Journal of Materials Research, 23, 1466–1471. https://doi.org/10.1557/jmr.2008.0184.

Guan, Q. F., Yang, H. B., Han, Z. M., Ling, Z. C., & Yu, S. H. (2020). An all-natural bioinspired structural material for plastic replacement. Nature Communications, 11, 5401. https://doi.org/10.1038/s41467-020-19174-1.

Amini, A., Khavari, A., Barthelat, F., & Ehrlicher, A. J. (2021). Centrifugation and index matching yield a strong and transparent bioinspired nacreous composite. Science, 373, 1229–1234. https://doi.org/10.1126/science.abf0277.

Lossada, F., Zhu, B., & Walther, A. (2021). Dry processing and recycling of thick nacre-mimetic nanocomposites. Advanced Functional Materials, 31, 2102677. https://doi.org/10.1002/adfm.202102677.

Chen, K., Tang, X., Jia, B., Chao, C., Wei, Y., Hou, J., Dong, L., Deng, X., Xiao, T. H., Goda, K., & Guo, L. (2022). Graphene oxide bulk material reinforced by heterophase platelets with multiscale interface crosslinking. Nature Materials, 21, 1121–1129. https://doi.org/10.1038/s41563-022-01292-4.

Müller, U., Halbauer, P., Stadlmann, A., Grabner, M., Al-musawi, H., Ungerer, B., & Pramreiter, M. (2023). “Wood-nacre”: Development of a bio-inspired wood-based composite for beam and 3D-surface elements with improved failure mechanisms. Journal of Bionic Engineering, 20, 1701–1711. https://doi.org/10.1007/s42235-023-00343-z

Wang, R. Z., Wen, H. B., Cui, F. Z., Zhang, H. B., & Li, H. D. (1995). Observations of damage morphologies in nacre during deformation and fracture. Journal of Materials Science, 30, 2299–2304. https://doi.org/10.1007/BF01184577.

Peng, X. L., Lee, S., Wilmers, J., Oh, S. H., & Bargmann, S. (2022). Orientation-dependent micromechanical behavior of nacre: In situ TEM experiments and finite element simulations. Acta Biomaterialia, 147, 120–128. https://doi.org/10.1016/j.actbio.2022.05.033.

Gopalan, H., & Chokshi, A. H. (2018). The mechanical behavior of nacre across length scales. Journal of the Mechanical Behavior of Biomedical Materials, 78, 96–107. https://doi.org/10.1016/j.jmbbm.2017.10.018.

Jiao, D., Qu, R. T., Weng, Z. Y., Liu, Z. Q., & Zhang, Z. F. (2019). On the fracture mechanisms of nacre: Effects of structural orientation. Journal of Biomechanics, 96, 109336. https://doi.org/10.1016/j.jbiomech.2019.109336.

Barthelat, F. (2010). Nacre from mollusk shells: A model for high-performance structural materials. Bioinspiration & Biomimetics, 5, 035001. https://doi.org/10.1088/1748-3182/5/3/035001.

Liang, S. M., Ji, H. M., Li, Y. Y., & Li, X. W. (2021). An ingenious microstructure arrangement in deep-sea Nautilus shell against the harsh environment. ACS Biomaterials Science & Engineering, 7, 4819–4827. https://doi.org/10.1021/acsbiomaterials.1c00956.

Li, H. Z., & Li, X. D. (2019). The art of curved reinforcing in biological armors - seashells. Journal of Bionic Engineering, 16, 711–718. https://doi.org/10.1007/s42235-019-0057-9.

Bouville, F., Maire, E., Meille, S., Van de Moortele, B., Stevenson, A. J., & Deville, S. (2014). Strong, tough and stiff bioinspired ceramics from brittle constituents. Nature Materials, 13, 508–514. https://doi.org/10.1038/nmat3915.

Shi, A., Li, Y., Liu, W., Xu, J. Z., Yan, D. X., Lei, J., & Li, Z. M. (2019). Highly thermally conductive and mechanically robust composite of linear ultrahigh molecular weight polyethylene and boron nitride via constructing nacre-like structure. Composites Science and Technology, 184, 107858. https://doi.org/10.1016/j.compscitech.2019.107858.

Cao, C. F., Yu, B., Huang, J., Feng, X. L., Lv, L. Y., Sun, F. N., Tang, L. C., Feng, J., Song, P., & Wang, H. (2022). Biomimetic, mechanically strong supramolecular nanosystem enabling solvent resistance, reliable fire protection and ultralong fire warning. ACS Nano, 16, 20865–20876. https://doi.org/10.1021/acsnano.2c08368

Huang, Z. W., & Li, X. D. (2009). Nanoscale structural and mechanical characterization of heat treated nacre. Materials Science and Engineering C, 29, 1803–1807. https://doi.org/10.1016/j.msec.2009.02.007.

Li, Y. Y., Liang, S. M., Ji, H. M., & Li, X. W. (2022). Distinctive impact of heat treatment on the mechanical behavior of nacreous and crossed-lamellar structures in biological shells: Critical role of organic matrix. ACS Biomaterials Science & Engineering, 8, 1143–1155. https://doi.org/10.1021/acsbiomaterials.1c01538.

Li, X. D., Xu, Z. H., & Wang, R. Z. (2006). In situ observation of nanograin rotation and deformation in nacre. Nano Letters, 6, 2301–2304. https://doi.org/10.1021/nl061775u.

Taylor, J. D., Kennedy, W. J., & Hall, A. (1969). The shell structure and mineralogy of the Bivalvia, Introduction, Nuculacea-Trigonacea. Bulletin of the British Museum (Natural History) Zoology, 3, 1–125. https://doi.org/10.5962/p.312694

Sun, J., & Guo, W. (2010). Chemical-mechanical stability of the hierarchical structure of shell nacre. Science China-Physics Mechanics & Astronomy, 53, 380–388. https://doi.org/10.1007/s11433-010-0134-x.

Papker, A., Immel, F., Guichard, N., Broussard, C., & Marin, F. (2016). Thermal stability of nacre proteins of the Polynesian pearl oyster: A proteomic study. Key Engineering Materials, 672, 222–231. https://doi.org/10.4028/www.scientific.net/KEM.672.222.

Liang, S. M., Ji, H. M., & Li, X. W. (2023). The crucial role of platelet stacking mode in strength and toughness of nacre. Materials & Design, 230, 111987. https://doi.org/10.1016/j.matdes.2023.111987.

Yoshioka, S., & Kitano, Y. (1985). Transformation of aragonite to calcite through heating. Geochemical Journal, 19, 245–249. https://doi.org/10.2343/geochemj.19.245.

Leung, H. M., & Sinha, S. K. (2009). Scratch and indentation tests on seashells. Tribology International, 42, 40–49. https://doi.org/10.1016/j.triboint.2008.05.015.

Bezares, J., Asaro, R. J., & Hawley, M. (2010). Macromolecular structure of the organic framework of nacre in Haliotis rufescens: Implications for mechanical response. Journal of Structural Biology, 170, 484–500. https://doi.org/10.1016/j.jsb.2010.01.006.

Bezares, J., Peng, Z., Robert Asaro, J., & Zhu, Q. (2011). Macromolecular structure and viscoelastic response of the organic framework of nacre in Haliotis rufescens: A perspective and overview. Theoretical and Applied Mechanics, 38, 75–106. https://doi.org/10.2298/TAM1102075B

Xu, Z. H., & Li, X. D. (2011). Deformation strengthening of biopolymer in nacre. Advanced Functional Materials, 21, 3883–3888. https://doi.org/10.1002/adfm.201100167.

Gim, J., Schnitzer, N., Otter, L. M., Cui, Y., Motreuil, S., Marin, F., Wolf, S. E., Jacob, D. E., Misra, A., & Hovden, R. (2019). Nanoscale deformation mechanics reveal resilience in nacre of Pinna nobilis shell. Nature Communications, 10, 4822. https://doi.org/10.1038/s41467-019-12743-z.

Tang, M., & Pistorius, P. C. (2017). Anisotropic mechanical behavior of AlSi10Mg parts produced by selective laser melting. JOM, 69, 516–522. https://doi.org/10.1007/s11837-016-2230-5

Wang, X., Fang, J., Zhu, W., Zhong, C., Ye, D., Zhu, M., Lu, X., Zhao, Y., & Ren, F. (2021). Bioinspired highly anisotropic, ultrastrong and stiff, and osteoconductive mineralized wood hydrogel composites for bone repair. Advanced Functional Materials, 31, 2010068. https://doi.org/10.1002/adfm.202010068.

Standfest, G., & Zimmer, B. (2008). The surface hardness of thermally treated woods. Proceedings of the International Convention of the Forest Products Society, St. Louis, MO, USA, 22–24.

Zeng, X., Ye, L., Yu, S., Li, H., Sun, R., Xu, J., & Wong, C. P. (2015). Artificial nacre-like papers based on noncovalent functionalized boron nitride nanosheets with excellent mechanical and thermally conductive properties. Nanoscale, 7, 6774–6781. https://doi.org/10.1039/C5NR00228A.

Wang, J., Liu, D., Li, Q., Chen, C., Chen, Z., Naebe, M., Song, P., Portehault, D., Garvey, C. J., Golberg, D., & Lei, W. (2021). Nacre-bionic nanocomposite membrane for efficient in-plane dissipation heat harvest under high temperature. Journal of Materiomics, 7, 219–225. https://doi.org/10.1016/j.jmat.2020.08.006.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Grant No. 51902043), and the Fundamental Research Funds for the Central Universities (Grant Nos. N2102002, N2102007 and N180203018). This work was also partially supported by the National Natural Science Foundation of China (No. 52171108).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, S., Li, Y., Ji, H. et al. Anisotropic Mechanical Response of Nacre to Heat Treatment Under Indentation: Effect of Structural Orientation. J Bionic Eng (2024). https://doi.org/10.1007/s42235-024-00508-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42235-024-00508-4