Abstract

This study is the first part of a larger investigation into the fire behaviour of green façades. In this study, the currently known international research status on this topic is presented and discussed. In addition, the flammability of green façades is investigated through 43 fire tests on a medium scale according to the SBI (Single Burning Item) test method EN 13823. The focus of the investigation was placed on climbing plants. A total of 25 different plant species were investigated. A comparison of the heat release rate of all the investigated vital plants shows similar behaviour. In the course of exposure, there are short peaks in the heat release rate. These peaks are “flare-ups” that occur when parts of the plants dry out due to exposure to the flame and then ignite. The plant species itself had no substantial influence on fire behaviour. Horizontal fire spread occurred to a very limited extent within the investigations of vital plants. They were self-extinguishing. The significant factor in the assessment of flammability is the moisture content of the plants. With dried plants, an abrupt heat release occurs at the beginning. Dried-out plants, as well as unmaintained plants with a high content of deadwood, represent the most critical case.

Graphical Abstract

Similar content being viewed by others

1 Introduction

1.1 General

In recent years, green façades (also called vertical greenery systems) have become increasingly important. Although cities occupy only 2% of the global land area, more than half of the world’s population lives in cities and urban agglomerations. Three-quarters of Europe’s population live in urban areas, and this proportion is forecast to increase sharply [1]. The resulting need for sustainable urban development requires a sufficient amount of green and recreational space. However, the increasing shortage of residential areas often stands in the way of the creation of new public green spaces and thus creates major challenges for the responsible authorities.

One possible solution would be the greening of the numerous existing horizontal and vertical building surfaces. Green façades offer multiple benefits, including improving air quality, minimising the heat island effect (or urban heat island = significantly warmer area in cities than surrounding rural areas), improving the thermal performance of the building, reducing noise through absorption and providing additional oxygen [2,3,4,5,6,7,8].

However, the fire safety aspects of green façades have not yet been investigated in detail.

1.2 Green Façade Systems

Figure 1 shows the various types of green façades. In principle, a differentiation can be made between direct greening on the exterior wall using climbing plants, indirect greening controlled by trellises and climbing aids set off from the exterior wall, or greenery wall systems using shrubs and bushes in boxes or substrate systems (living wall). Mixed types are also possible [8].

Types of green façade design. 1 Direct growth with self-climbers, ground-based, 2 Growth on climbing aid/trellis, ground-based, 3 Plant boxes, horizontal vegetation surfaces, wall-based, 4 Modular system (living wall), vertical vegetation surfaces, wall-based, and 5 Planar system (living wall), vertical vegetation surfaces, wall-based; based on [8]

Greenery wall systems (without ground contact) are characterised by built-in irrigation systems, plants of various sizes and the interchangeability of plants. These enable an extensive greening of the façade from the moment the building is completed through module or shelf systems [8].

In a recent study [9], 142 products from 58 manufacturers from Asia (India, Taiwan, Turkey), the Americas (Canada, USA, Chile), Europe (Austria, Czech Republic, France, Germany, Hungary, Italy, Netherlands, Slovenia, Spain, Sweden, Switzerland, United Kingdom) and Australia were analysed. The number shows the increasing interest in these systems. It should be noted, however, that this study looked for manufacturers offering a complete system. Of the 142 products, 24 (approx. 17%) belonged to types 1 and 2 (Fig. 1), while the rest belonged to living walls (approx. 83%). Here, a distinction must be made between “indoor” and “outdoor” applications. Since climbing plants on trellises are also regularly supplied by medium-sized nurseries, the number of products in the respective countries increases significantly [9].

An evaluation of 54 fire incidents [10] with green façades (press article collection in an observation period of approx. 5.5 years) shows that in most cases, ivy (Hedera helix) was involved. Due to the relatively high accumulation of dead plant parts (deadwood in H. helix), which is favoured by the plant characteristics “negatively phototropic” and “evergreen”, H. helix fires have led to a sometimes rapid and extensive fire spread. The real fire events prove that fires on green façades usually proceed in a very similar way. First, the dry foliage ignites, followed by the deadwood and any combustible climbing aid. In most cases, the dry plant parts burn within a few seconds. After the deadwood has burned, the fire often extinguishes on its own. Façade areas with vital and well-maintained plants generally do not contribute to fire spread [10].

1.3 Plant Species Basics

The use of climbing plants for green façades has many regional peculiarities [8, 11, 12]. The species potential for climbing plants in the central European climate region consists of approx. 150 species and varieties [11].

An evaluation of plant lists for tropical and subtropical regions revealed a potential of more than 1000 plant species and varieties, of which only a small percentage is currently available in nurseries [13].

The range of possible plant species for wall-based planting systems encounters only a few restrictions and is, therefore, much more extensive. For the central European climate region, approx. 100 species and varieties are listed in [12]. A differentiation is made between perennials, grasses and woody plants [8, 11, 12].

The most important characteristics for the categorisation of plants are deciduous, semi-deciduous, evergreen, and the presence of a negative phototropic (light-fleeing) characteristic [8, 11, 12].

Evergreen and semi-deciduous plants, unlike deciduous plants, have foliage all year round. The difference between evergreen and semi-deciduous plants is that semi-deciduous species retain their foliage, but unlike evergreen plants, they drop their foliage in spring just before the foliage shoots again. A negative phototropic characteristic is the tendency of the shoots to grow away from the light. This characteristic leads to a high amount of hardened and dried material and the occurrence of structural damage if care and maintenance are lacking. An example of a plant with a negative phototropic (light-fleeing) property is ivy (H. helix) [8, 11, 12].

1.4 Basics of the Flammability and Ignitability of Plants

Extensive work on flammability of living vegetation has been conducted in the USA. White et al. [17] summarised the results from several studies as follows “[…] flammability characteristics are affected by several factors which can be classified into two groups: (1) physical structure and components (e.g. branch size, leaf size and shape and retention of dead material); and (2) physiological or cellular elements (e.g. volatile oils and resins, moisture content, mineral content, lignin and waxes) […]” [17].

That the moisture content of plants is an important parameter for describing their flammability and heat release has been known for a long time. For example, the increasing flammability of dry Christmas trees [18,19,20].

Research on wildland fires shows that moisture content plays an extremely important role in the ignitability of natural fuels [21, 25]. The moisture content affects flammability both physically (increasing thermal capacity of the material) and chemically (inhibiting the combustion process) [21, 23]. The studies found a highly significant positive correlation between the moisture content of the leaves and the ignition time. The ignition time increases with higher moisture content [24]. This includes leaves, trees, grasses and shrubs. The moisture content also influences the rate of fire spread. Generally, the lower the moisture content, the more intense these phenomena become [26,27,28,29,30,31,32]. An investigations of shrub fires [33] concluded that: “A twofold increase in moisture content from 40% to 80% for instance results in a 63% increase in time required for complete burning of the shrub. It is also found that flames begin to extinguish at higher moisture contents even though a considerable amount of unburnt solid fuel is present in the shrub. The cause of these phenomena was found to be that fuel particles undergoing combustion did not generate sufficient energy required to initiate ignition of neighbouring fuel particles resulting in an increase in the amount of unburnt mass” [33].

Results from studies show that the moisture content of new and old plant parts can be significantly different within the growing season. New foliage has a higher moisture content compared to old foliage [27, 34,35,36,37,38,39]. The moisture content of new foliage is highest at the time of emergence. A moisture content that is two or three times the organic dry weight is common [40]. “The moisture content of old foliage changes only slightly during the season, while that of new foliage is very high at emergence and then drops, first rapidly, then more slowly, matching that of the old foliage at the end of the growing season” [40], as shown in Fig. 2.

Variation of the moisture content of foliage over a season [40]

Some studies have concluded that the flammability of plants may change with age due to changes in structure (foliage fraction, dead material), maintenance (irrigation, dead material, pruning) and possibly a reduction in the moisture content of mature foliage [21]. Reference [22] shows, for example, that the ignition behaviour of live fuels in different seasons, but at the same moisture content, is different.

The living foliage of evergreen species is usually more flammable than that of deciduous species. There are several reasons for this, but the most important are the differences in moisture regimes. Deciduous foliage is the growth of the current year and has a relatively high moisture content during most of the growing season. Evergreen plants, on the other hand, especially those that retain their foliage for several years, have much lower average foliage moisture during the growing season. Old-growth foliage, with its lower moisture content, can constitute 80% or more of the total evergreen foliage volume. There is also a greater tendency for evergreen species to have a mixture of dead foliage, twigs and branches [40]. The age of the plant, therefore, plays a role in ignitability [41].

The location of a plant and the local conditions can also influence the moisture content [26]. The moisture content of living and dry plants is also relevant to the seasonal occurrence of fires [42]. Depending on the species, the seasonal influence is stronger or weaker. This fact explains the frequency of fires in summer and early autumn after a hot period and in spring after a dry period [36,37,38,39]. Obviously, the determination of the moisture content of fuels is one of the important but also very complex components of wildfire prevention and management [43, 44].

Moisture content (MC) is typically calculated by dividing the difference between the wet mass (mwet) and the dry mass (mdry) by the dry mass and expressing this as a percentage. This method is used internationally, for example, to express the moisture content of wood [48, 49]. Usually, the material is dried in an oven until there is no more loss of mass. Equation (1) describes this calculation procedure.

As previously described, the moisture content of plants is one of the key factors in wildland fire risk assessment. In research, fuel models are used for this purpose. An important factor for these models is the moisture content of the fuels and the resulting influence on the vitality of the plants. Rothermel [50] established a guideline for estimating moisture content in foliage, as shown in Table 1.

Scott et al. [51] later extended these models. The moisture content of vegetation was also defined as an input parameter. Figure 3 shows the influence of moisture content on the vitality of herbaceous plants.

Level of curing (fraction of dead plants) in relation to the herbaceous moisture content [51]

Reference [52] specifies moisture contents of 26% for dead fuels and 100% for live fuels.

Another influence on the flammability of plants is the existence of essential oils and resins. The essential oils and resins result in a lower ignition temperature and a higher calorific value of heat release [28, 45]. The high calorific output will tend to promote further flaming [46]. The gases emitted during the combustion of essential oils can further increase the spread of fire [47].

The arrangement of the leaves can also have an influence on the burning characteristics of the plant. The ignition time was delayed with increasing leaf size [53].

In addition, weather influences such as wind can have a significant impact on the flammability of plants [54, 55]. In [55], for example, the influence of wind on the flame characteristics of leaves was investigated. In most cases, the wind-burned specimens had longer times for ignition, complete burning as well as burning duration of the specimen at lower temperatures in each case. The wind (parallel to the leaf surface) cooled the specimens by convection, which led to longer ignition times and lower temperatures [55].

Rahimi Borujerdi et al. identified as a major finding for fire spread in wildland fires that: “Combustion of the gaseous components of the pyrolysis products is one of the key processes responsible for spread of fire in wildland fuels” [56]. The effect of heating mode, moisture status (including live vs. dead plants) and plant species on the composition of the plant pyrolysates can additionally be taken from [57,58,59,60,61,62,63,64,65]. Based on the pyrolysis product distributions observed in these experiments, differences in fire behaviour of live and dead fuels should be largely due to moisture content [60, 61]. Reference [63] shows that the condition of the plant (live or dead) did not affect the number of pyrolysis peaks of a particular plant species. The results of these studies can help to determine the heat release of the plants, for example for computational fluid dynamics (CFD) modelling [66, 67].

The ignition temperatures of vegetation have been investigated in numerous studies. However, the reported values are very inconsistent. Due to the different chemical compositions of various vegetation types and seasonal changes, there are variations in ignition temperatures. However, most plants of a particular type (e.g. foliage, needles, etc.) can generally be expected to show little variation in ignition temperature [14]. The pilot ignition temperature of foliage is in the range 227°C to 453°C and of small woody shoots in the range 350°C to 675°C [15, 16, 70, 71]. Reference [70] concludes that the ignition temperature, unlike the ignition time, is not directly dependent on the size and shape of the sample. It seems clear that the ignition of the foliage begins at a time when moisture is still present [55, 64, 68, 69]. Reference [72], on the other hand, concludes that almost all the moisture had evaporated from the fuel at the time of ignition. In [64] it was observed that bound water is only released at temperatures close to 200°C.

Furthermore, there is a lack of standardisation of methods for assessing the flammability of vegetation [17, 37]. “The lack of consensus on fire testing of vegetation also likely reflects a view that ‘flammability’ is a state of ‘quality’ rather than a quantifiable property” [17]. The most common test methods are listed in [17].

2 Analysis of Existing Experimental Investigations

2.1 General

Overall, scientific knowledge about the fire behaviour of green façades is very limited. For this reason, it seems helpful to use similar models from wildland fire research. For example, studies on transition and fire spread behaviour from surface fuel fires to crown fuel fires can provide knowledge [73, 74]. A surface fire transition to a crown fire when the intensity of surface burning surpasses a critical value determined by the properties of the burning material in the crown [74]. The ignition energy is influenced by the moisture content of the foliage. Other influencing factors are the wind speed, the distance between the crown and the fire and the density of the crown [73, 74].

The studies show that wind increases fire spread, which is reflected in the increase in heat release rate, spread rate and flame height in wind-driven fires compared to non-wind-driven fires [73]. The greater the distance between the crown and the surface, the slower the fire spreads to the crowns [73]. Higher bulk density in crowns results in slower passage of hot fire gases through the crowns, leading to increased heating due to increased convection and higher probability of successful foliage ignition [74].

These findings show that moisture content (see also Sect. 1.4), plant density and wind can have a decisive influence on the fire spread and must be taken into account in further investigations of green façades.

2.2 Studies on the Flammability of Plants for Green Façades

Dahanayake et al. [75] investigated the influence of the moisture content of plants on their ignitability and fire hazard. For this purpose, the three different plants, H. helix, Peperomia obtusifolia, and Aglaonema commutatum, were investigated in cone calorimeter experiments [76], taking into account different moisture contents in the drying process. Fresh plant specimens of all three species did not ignite at any heat flux level in the test (from 20 kW/m2 to 60 kW/m2). The moisture content of the fresh living plants showed differences; H. helix had the lowest moisture content of 326%, while P. obtusifolia and A. commutatum had contents of 1371% and 1150%, respectively. The specimens started to ignite once their MC had reached a certain value, as shown in Fig. 4. The study concludes that healthy and living plants are the most important basis for ensuring a minimal fire risk [75].

Ignition time (TTI) at different radiant heat fluxes and under different moisture contents (MC) for Hedera helix, Peperomia obtusifolia and Aglaonema commutatum [75]

At the University of Vienna, the fire behaviour of plants for green façades was investigated in a muffle furnace as part of student projects. The chosen plants were thermally exposed in [77] at a constant temperature of approx. 850°C and in [78] at different temperatures in a muffle furnace. The aim was to identify the time and duration of smoke and fire development. Although differences were found, 65% and, therefore, the majority of the tested plant species were categorised as “highly flammable” [77].

The Department for Communities and Local Government [79] in London conducted cone calorimeter tests on specimens of a growing medium for living walls. The growing medium consisted of medium-textured peat and coir with added wood fibre, perlite, lime-based nutrients and controlled-release fertiliser with added wetter and insect control. The material for the three tests was dried in an oven at 40°C before the cone calorimeter tests were carried out at 50 kW/m2. No ignition was observed in any of the tests [79].

2.3 Fire Tests on Green Façades

The Department for Communities and Local Government’s publication [79] also refers to five Single Burning Item tests (SBI) [80] on green wall systems. The tests were carried out with living walls. However, no plants were installed in these systems. All tests had to be stopped before reaching the 10th min. In three of the tests, the heat release reached more than 350 kW, and in two tests, the specimens collapsed onto the burner. Overall, these tests are very manufacturer-specific due to the pure testing of the system without greening and are, therefore, not very meaningful [79].

In addition, a number of manufacturers have conducted SBI fire tests [80] for their green living walls [81,82,83,84,85,86]. A description of the test specimens and the results of the 11 tests are given in the “Appendix” (Table 5). A total of three different types of living walls from different manufacturers were tested. Some with plants, some without.

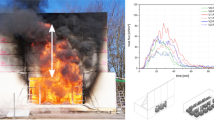

Engel et al. [87] investigated the flammability of green façades in four medium-sized experiments as part of a student research project [88]. The façade test stand was a structure 4 m high and 2 m wide, with a fire chamber in the centre of the lower area. Spindle (Euonymus fortunei), Japanese wisteria (Wisteria floribunda), Virginia creeper (Parthenocissus quinquefolia) and a plant mix of herbs and shrubs (typical for wall-based systems) were used as greenery. During the experiments, some plant species burned more, less or not at all. The experiments cannot be directly compared to each other due to the different plant quantities, but they provide initial findings. If a plant was actively burning or limited vertical fire spread took place, this occurred through a brief flare-up of dried-out parts, as shown in Fig. 5 (11th min). There was no horizontal fire spread. Self-extinguishing occurred after the primary fire had stopped [87].

Temperature–time diagram for a medium-scale façade fire experiment with euonymus fortune, based on [87] (Color figure online)

Werner et al. published a first study [89] with four full-scale façade fire tests in 2018 and a second study [90] with seven full-scale façade fire tests in 2020. These fire tests represent the largest database for this research topic at the present time. Therefore, most of the technical specifications in guidelines, especially in Europe, can be referred back to these results [92,93,94,95]. The basis for the façade fire tests was the standard ÖNORM B 3800-5 [96]. The test specimen for the façade test stand consisted of a 5 m high inner corner with a long segment of 3 m width and a narrow segment of 1.5 m width. The fire chamber (1 m × 1 m) was located directly in the inner corner of the long segment. Wooden cribs were used as the fire load. The detailed test setups and the results are shown in Table 6 in the “Appendix”. In the first study [89], ground-based green façades were investigated. The study varied between direct growth with self-climbers and growth on climbing aids/trellises and with regard to the vertical distances between the plants and the fire chamber. In all tests, vertical fire spread occurred in the form of recurrent short-term burning of dried plant parts (several brief flare-ups). According to the authors, the plants participate in burning at temperatures of approx. 500°C and above. Based on the findings in Sect. 1.4, however, these values must be critically questioned. There was no horizontal fire spread. After the end of the experiment, self-extinguishing occurred. In the second study [90], wall-based living walls with plant boxes with and without fire stops were also investigated. In the case of ground-based green façades climbing aids and trellises, the focus was on the distance between the climbing aid and the test stand wall. If a fire on the green façade was not prevented by technical means (projecting sheet steel fire stop located directly above the fire chamber), the burning of the green façade proceeded as in the first study. The results provide an important basis for the general classification of the flammability of green façades but must also be viewed critically with regard to the measures to be defined for reality. The reason for this is that the façade fire test according to ÖNORM B 3800-5 [96], which largely corresponds to the German DIN 4102-20 [97] test, was originally calibrated explicitly for testing composite external thermal insulation systems made of expanded polystyrene. The fire load in the form of a wooden crib of 25 kg does not correspond to the flame of a typical compartment fire [98] and is only to simulate a flame, which results in a similar temperature in the lintel area of the opening [99, 100]. This means that the façade test used here provides important results but does not represent reality. However, the results were directly transferred to reality (especially with regard to the technical measures), taking into account evaluation criteria that were not designed for green façades. The increase of the fire load from 25 kg to 50 kg for the last three tests does not change this. Furthermore, there are uncertainties regarding the reproducibility of the tests. For example, in test No. 3 of the second study [90], significantly fewer plants were arranged in the inner corner than in test No. 2, but the tests were directly compared in the evaluation. The structural measures derived from the tests, which are currently defined in some of the guidelines [92,93,94,95], must be taken with care because of the currently missing link and proof of adequacy between ÖNORM B3800-5 [96] and real fire incidents [89, 90].

The company Vertiko conducted a façade fire test [101] in accordance with DIN 4102-20 [97] on its wall-based living wall. The system consists of a vertical wall-based vegetation surface consisting of support profiles, rear-ventilated void cavity incl. fire stops, cladding panels (aluminium composite panel with mineral wool core), fleece (glass fibre fleece, cover fleece with PU-based colour coating), irrigation system, mineral substrate and various plants. The plants directly next to and above the primary flame burned down to the upper edge of the test stand (brief flare-ups). The surface of the composite fleece discoloured mainly due to soot. After the end of the fire test (turning off the burner), two small flames continued to burn at the fire chamber lintel but extinguished on their own within 2 min. The flames in the rear-ventilated void cavity could not pass the first fire stop. The temperatures in this area were too low to melt the aluminium substructure. Considering the temperature measurement in the rear-ventilated void cavity, in addition to the fact that the fire could not pass the first fire stop (0.5 m height), it can be seen that the living wall protected or insulated the rear wall of the test stand from the direct temperature effect of the primary flame, as shown in Fig. 6 [101].

Temperature–time diagram (left) in the rear-ventilated void cavity in different heights [0.5 m above the fire chamber (under fire stop), 1.0 m and 1.5 m above the fire chamber (above fire stop)]; photo of the test stand with arrangement of the measuring points in the rear-ventilated void cavity; based on [101]

The company hhpberlin conducted a fire test [102] as part of a master’s thesis [103]. The basis of the façade fire tests was the standard DIN 4102-20 [97]. The test specimen consisted of a 6 m high and 2.43 m wide wooden façade with a green façade in front. The wooden façade was a rear-ventilated horizontal tongue-and-groove formwork made of spruce wood. Stainless steel climbing aids were placed in front at a distance of 160 mm. As greenery, E. fortunei was arranged on the left half of the climbing aid and Actinidia arguta on the right half. The wooden façade was divided by fire stops at heights of 1.75 m and 4.55 m, according to [104]. The green façade ran over the fire stops. The fire chamber on the base of the test stand (1 m × 1 m) was located directly in the middle of the façade. A gas burner with a gas pressure rate of 7.4 g/s and an air supply of 24 m3/h from the rear of the combustion chamber was used in the test. From approx. 1.5 min after the start of the test, the first brief flare-ups of the greening occurred. This phenomenon only occurred in the area directly above the primary flame. By the 8th min, a large part of the vegetation in the area above the primary flame had been burned by short flare-ups, and the primary flame had reduced significantly. The reduced flame was also due to the occurrence of charring on the wooden façade. Ignition of the wooden formwork outside the primary fire area due to the flare-ups of the greening did not occur, although short-term temperatures of up to 340°C (higher than the ignition temperature of wood 300°C [105]) were measured several times on the wooden cladding outside the primary flame [102, 103].

As already noted for the Vienna fire tests, the test conditions must also be taken into account when directly transferring the results from the two studies (following DIN 4102-20) mentioned before to reality.

For the realisation of a storey-by-storey green façade on a high-rise building, the fire spread over the façade had to be investigated by conducting full-scale fire tests [106]. In this high-rise building, fire spread from storey to storey is prevented by 1.60 m horizontal concrete projections at ceiling level. On these projections, plant boxes with climbing plants are arranged in each storey. The plants are located directly at the front end of the projection (distance approx. 10 cm to 20 cm). For the investigation, a real fire test scenario was designed consisting of a three-storey test structure and a fire load of 140 kg (4 × 35 kg) wooden cribs. The choice of fire load quantity and arrangement was made for realistic exposure [107]. During the fire test, the climbing plants on the two floors above the fire level did not ignite. There was no fire spread above the storey boundary. Figure 7 shows the test setup and the maximum temperatures measured in the axis of the green façade. Unfortunately, the results cannot be presented in more detail due to the confidentiality agreement within the scope of the industrial contract [106].

3 FireSafeGreen Research Project: Single Burning Item (SBI) Test Series

3.1 Aim of the Study

The overall aim of the project FireSafeGreen is to extend the knowledge about the behaviour of green façades when exposed to fire and its influence to flame spread on façades. Further the project aims to identify constructive measures and general principles under which it is possible to use green façades in a product neutral and fire safe manner. The project includes a multi-pronged investigation strategy with tests about the fire behaviour of plants in Single Burning Item (SBI) tests and full-scale façade fire tests. This publication only describes the findings of the SBI fire tests.

With regard to Sects. 1.2, 2.3 and Table 5 of the “Appendix”, living walls (types 4 and 5 in Fig. 1) are not considered in the following investigation, because living walls represent an integral producer specific system with a rear-ventilated void cavity, supporting structure, cladding panels, substrate, fleece, irrigation system and the plant itself. The systems differ significantly between the manufacturers. The shrubs and herbs (pure plant mass) typically used for such systems only play a minor role with respect to the entire fuel load of the system. A product-neutral analysis is therefore not possible and living walls can therefore only be meaningfully investigated in large-scale tests on the respective complete system.

The focus of the following study is on climbing plants on non-combustible trellises and climbing aids (types 1 and 2 in Fig. 1).

The first series of tests within the research project FireSafeGreen was to provide information on the fire behaviour of the plants/plant systems used for green façade systems. The following questions were investigated in more detail:

-

Do the plants self-extinguish after the primary fire has stopped?

-

What heat release occurs through the plants?

-

What influence does the plant species have on fire behaviour?

-

To what extent does vertical or horizontal fire spread occur?

-

What influence does the presence of essential oils have on fire behaviour?

-

What role does the age of the plants play in relation to fire behaviour?

-

What role does the moisture content of the plant play in relation to the fire behaviour?

Ultimately, the above questions must always be viewed in the context of the large-scale end application. Due to the large number of potentially possible plant species for use as façade greening, a comparison is made with regard to the aforementioned questions using the European SBI test procedure. This is followed by further full-scale fire tests.

As described before, the focus of this study was on climbing plants. The shrubs and herbs commonly used for living walls also represent a comparable plant mass. For this reason, some of these plants were also investigated in this series of tests but were not the primary focus.

It is important to note that in most industrialised countries, such as in the European Union [108], only manufactured products are construction products in the legal sense. This also applies to the building codes of the Member States [87]. After taking this classification into account, it can be stated that the trellises and climbing aids of green façades and living walls are considered construction products. The plants of the green façade, as a non-manufactured product, cannot be classified without doubt as a construction product. Standardised fire tests, which are used to classify building products, are therefore only to be valued as an orientation. However, it is clear that the basic protection goal of limiting the fire spread along the façade is also still relevant here.

3.2 Test Setup

The test was carried out according to the SBI (Single Burning Item) method and complied with EN 13823 [80]. The test specimen in the form of plants consisted of one side with an area of 1 m × 1.5 m and one side with an area of 0.5 m × 1.5 m (W × H), as shown in Fig. 8.

It is known from previous studies [17, 21, 109] that the specimen size has an impact on flammability. It makes a difference whether plant parts or whole plants are used. In small-scale fire tests, it is mainly the flammability of the plant parts that is investigated, and in larger-scale tests, it is more the flammability of the whole plant [17, 21, 109]. In addition, the aim of the study was to investigate influences on the plant's flammability in the context of a large-scale arrangement on a façade. As described in Sect. 3.1, the focus was on comparative analysis of different plants with respect to its heat release and flame spread and quantifying the influence of the plants within the SBI fire test scenario but not on the exact quantification of the flammability for building products. These results will be used in the further progress of the research project to design full-scale façade fire tests with green façades. For this reason, the SBI test [80] was chosen to investigate the flammability of plants for green façades. In this medium-scale test method, whole areas of plants and not just plant parts can be investigated. Therefore, the results can be used to make conclusions about the behaviour of the entire plant and not just parts of it. The arrangement of the test specimen on the test stand with its 1.5 m high vertical surfaces in an inner corner also corresponds to the real situation on a façade. The exposure scenario of the gas burner as a base fire is also similar to the principle of a façade fire.

All tests were carried out with fresh plants, which were cut off from their roots directly in advance.

Trellises with a mesh size of 25 cm were used to fix the plants. These relatively large mesh sizes are common in practice for climbing plants and are intended to allow the foliage to fall seasonally. The exact arrangement can be seen in the videos in the supplementary material.

In consultation with research partners from science and practice, 20 climbing plants and 5 plants for living walls that are frequently used in Central Europe were identified, as shown in Table 2.

All plants listed in Table 2 were at least 3 years old. Considering the aspects of Sect. 1.3 and the fact that older plants usually have more woody shoots, it should represent typical realistic boundary conditions. In order to allow a comparison between young and old plants, additional plants (< 1 year) were used, such as H. helix. In this case, the descriptions “old” and “young” were added.

The plant mass used in the test specimen is also given in Table 2. Particular care was taken to arrange the plants densely over the entire area. To investigate the influence of plant vegetation density, some tests were carried out with a lower plant vegetation density. In this case, the tests are marked with (1) for low and (2) for normal density. “Normal vegetation density” corresponds to the usual arrangement of maintained plants on a façade. Due to the plant species, which goes hand in hand with the mass and size of the woody shoots, leaf size and density, flowers and fruits, different masses result even with visually equally intensive planting density. The basic growth behaviour taken from the literature is shown in Table 8 in the “Appendix”.

In order to investigate the influence of a reduction of the moisture content close to reality, two plants were cut off from the roots and stored at ambient temperature for 42 days before the test was carried out. The aim of this test was to show the influence of direct damage to a plant in the root area, including the drying out of the plants.

To investigate the possible seasonal influence on the fire behaviour of the plants, in addition to the tests in summer (fully grown plants), tests were also carried out in winter. These five tests are marked in Table 2 with the note “winter”. It should be noted that the H. helix, E. fortunei, Jasminum nudiflorum and Lonicera henryi tested in winter were each taken from the same plant. Except for Actinidia deliciosa, the tests were conducted with the same plant mass as the previous summer tests. Jasminum nudiflorum was flowering in winter at the time. Actinidia deliciosa had no foliage in winter. Therefore, according to the photo documentation, the shoots were arranged in the same position and mass as in summer. The total mass, therefore, differed from the values in summer. The focus here was on investigating a plant with foliage shedding.

In total, 43 SBI fire tests with plants as specimens were conducted. An overview of the investigated specimen is given in Table 2.

3.3 Test Procedure

The SBI test procedure proceeds in accordance with EN 13823 [80] and corresponds, in principle, to a calorimeter. The test and measurement procedure are described in detail in [80] and also in [110]. The SBI test is a test method for determining the reaction to fire performance of building products exposed to the thermal impact of a sand-box burner (30 kW). The details of the sand-box-burner are given in Table 3.

The test specimen is mounted on a trolley positioned in a frame under an exhaust system. The heat and smoke release rates are measured instrumentally and the physical characteristics are assessed by observation. The ignition of the auxiliary burner at the beginning is used to measure the heat and smoke release of the burner on its own. With the help of this measurement, the heat release of the burner can be subtracted from the total heat release and the results show only the heat release rate of the specimen [80]. The general procedure is briefly illustrated below, as shown in Fig. 9.

-

I.

From t = 0, the measurements are recorded.

-

II.

At t = 120 s, the auxiliary burner is ignited. The time period 210 s < t < 270 s is used to measure the baseline for the heat release rate of the burner.

-

III.

At t = 300 s, the gas supply is switched to the main burner, the main burner is ignited, and the auxiliary burner is switched off.

-

IV.

At t = 1500 s, the automatic measurement to evaluate the fire behaviour of the specimen is stopped.

-

V.

At t = 1560 s, the gas supply to the burner is stopped.

Illustration of the SBI test procedure according to EN 13823 [80]

3.4 Instrumentation

For the SBI test method according to EN 13823 [80], the measurement data is recorded in the exhaust duct. The exhaust hood located directly above the SBI test stand introduces all fire gases into this exhaust duct. The following measuring devices are located in this exhaust duct:

-

Hemispherical probe to measure the pressure difference in Pa with a measuring range of at least 0 Pa to 100 Pa and an accuracy of ± 2 Pa [112].

-

Light measurement section for measuring the light transmission in %.

-

Gas sampling probe for measuring the O2 mole fraction and the CO2 mole fraction in the exhaust gas stream in each case in the ratio of volume O2 or volume CO2 to volume air in %. The O2 gas analyser is a paramagnetic type with a measuring range of at least 16% to 21% oxygen. The response time of the analyser is less than 12 s. The noise and drift of the analyser is less than 100 ppm over a period of 30 min. The CO2 analyser is an infrared type with a measuring range of at least 0% to 10% carbon dioxide. The analyser has a linearity of at least 1% of the measuring range. The response time of the analyser is not more than 12 s [80].

-

Three sheath thermocouples of type K according to EN 60584-1 [111] (diameter 0.5 mm to 1 mm, insulated) on a radius of (87 ± 5) mm around the pipe axis and at a mutual angular distance of 120° for measuring the temperature in K.

In addition, the data logging system records the time in s (every 3 s), the propane mass flow through the burner in mg/s and the ambient temperature at the air inlet at the bottom of the specimen carrier in K [80].

The calibration procedure of the measurement can be taken from Annex C and Annex D of EN 13823 [80]. In the context of an SBI round robin test in 2015–2016 [80] with 86 tests on chipboard, a relative standard deviation of 5% for the total heat release of the first 600 s (main burner) was determined for the repeatability.

4 Results of the SBI Fire Tests

Table 2 shows for each individual test specimen the test time, the basis weight, the moisture content and the total heat release. The heat release rates are shown in Figs. 10, 11, 12, 13, 14, 15 and 16 for each test. The total heat release and the specimen mass (plant mass without trellis) for each of the tests are shown in Fig. 17.

Based on the SBI test campaign, the typical classification values according to EN 13501-1 [113] were determined for each specimen and listed informatively in Table 7 in the “Appendix”.

Figure 18 shows the burnt, withered and still vital areas of the test specimens after the SBI tests. For this purpose, the condition of the plants was visually recorded and documented on the test stand after each test. Vital or withered plant parts were determined by their appearance and by their behaviour while being touched (moist and elastic). Outside the primary flame, the plants were vital in all tests except Fallopia baldschuanica (No. 11 according to Table 2), H. helix (young)—dried (No. 16) and Humulus lupulus—dried (No. 18). In the case of F. baldschuanica, as shown in Table 2, the plants already had a low moisture content before the start of the test and were withered. In both dried tests, on the other hand, burning occurred over almost the entire test stand area.

Visualisation of the burnt or dried areas after the SBI tests, based on [114]

5 Discussion

5.1 General

As shown in Sect. 2, other studies followed the approach that the plant is responsible for the fire behaviour on the façade, among other things. The aim of this study was to develop initial tendencies for the influence of the plants on the façade fire.

Due to the number and general parameters of these tests (43 SBI tests with different parameters, e.g. plant species, old vs. young, vital vs. dried and different densities), there is no claim to a completely statistically correct survey for the final assessment of the flammability of plants for green façades. The scope of this study in terms of the number of specimens examined is significantly smaller than some studies on wildland fire research, as shown in Sect. 1.4. The focus of the project FireSafeGreen is on fire behaviour of large-scale green façades, as shown in Sects. 3.1 and 3.2. For this reason, the larger test specimen (SBI test) was chosen in comparison to the investigations in Sect. 1.4. The question of whether there are clear tendencies for different fire behaviour of the plants in a façade fire with corresponding high fire exposure (compartment, balcony or waste container fires) is the focus here. The question is not exactly how pronounced these influences are, but rather what influence they might have in the case of a large-scale arrangement on a façade. The results will be used in the further course of the research project for the design of full-scale fire tests with green façades. In the case of component tests, such as for a façade, it is common in fire research to generate results from single tests with regard to costs and effort [115]. The extent to which this procedure also applies to green façades needs to be investigated further.

To analyse the statistical variation, replicate tests were carried out for one plant species. Table 4 shows for the H. helix (old) replicate specimens the constant basis weight, the moisture content and the total heat release in the SBI tests. The heat release rates are shown in Fig. 19 for the replicate tests.

The replicate tests show a total heat release of 5.4 MJ to 6.6 MJ with a sample standard deviation of 0.43. The heat release of the specimen over time is similar. The flare-ups of the individual specimens are comparable in terms of quantity and magnitude. Based on this sample of replicate tests, a low variance is predicted for tests of the same type.

A comparison of the heat release rates of Figs. 10, 11, 12, 13, 14, 15 and 16 of all tests shows quite similar results for all vital plants (normal moisture content). The short peaks of the heat release rate in each case represent the “flare-ups” already explained in Sect. 2.3. This always happens when parts of the plants dry out due to the effect of the flame of the main burner, followed by the ignition and burning of these areas. In this test series, the flare-ups ranged from 10 kW to 60 kW (mean value 20 kW) difference to the heat release rate baseline, for a duration of 10 s to 50 s (mean value 20 s) each. The size of these flare-ups and, consequently, the heat release rate that occurs are directly dependent on the plant mass, density and the composition of leaf size and quantity (Sect. 1.4). The more foliage mass exists (size and proportion in relation to wood shoots), the more it will dry out and lead to abrupt flare-ups. This can be seen, for example, in Fig. 13. If comparing the two tests on L. henryi (Nos. 24 and 26 according to Table 2), in which the plant mass was increased more than four times between test Nos. 24 and 26, there is only doubling of the heat release rate, but remarkably more visible flare-ups. The reason for this is that dried foliage, fruits and flowers lead to flare-ups due to their low mass and large surface area, while woody shoots burn off at a relatively constant rate. Reference [116] shows for vegetation fires (in this case: chaparral) that live branches up to 1.3 cm can be burnt in the high-intensity flame front, while fuels with larger diameters normally do not burn. This underlines the fact that the foliage itself is in the focus of the combustion. The comparison of both tests (Nos. 11 and 12) with F. baldschuanica and (Nos. 19 and 20) with H. anomala shows that more plant mass does not necessarily lead to a higher heat release rate. As shown in Sect. 1.4, in addition to mass, a number of other factors, such as leaf arrangement and the distance between the leaves, are responsible for fire spread in the living plant fuel.

5.2 Role of Plant Species

Considering the average course of the heat release rate and most of the flare-ups, it can be seen that for vital plants, the influence of the plant species and other resulting factors such as the existence of essential oils, growth behaviour, foliage size, etc., play a subordinate role.

There are differences for vital plants in terms of the heat release rate in one of the two tests with F. baldschuanica at the beginning (Fig. 11), with C. radicans in terms of the relatively large flare-up (Fig. 10) and with W. sinensis in terms of the overall course compared to the other plants (Fig. 15).

The difference for F. baldschuanica (No. 11 according to Table 2) can be explained as follows. Since the tests were carried out with plants that were several years old, in the case of test No. 11, according to Table 2, a very woody test specimen was taken from the experimental gardens of the Weihenstephan-Triesdorf University of Applied Sciences. The test specimen consisted almost exclusively of relatively dry woody shoots with only very little foliage. This is also evident when considering the moisture content in Table 2. These relatively dry woody shoots burned quite quickly at the beginning in the area of the flame of the main burner. This explains the increased heat release rate at the beginning. Since this test is not representative of a green façade in this form, another test (No. 12 according to Table 2) was carried out with a plant that is also several years old but with six and a half times as much mass and with full foliage growth. In this representative test, there are no substantial differences compared to the other plants in the context of a large-scale arrangement of plants on a façade.

The particular behaviour of C. radicans (No. 6 according to Table 2) regarding the relatively large heat release peak at the 20th min is due to two reasons. Campsis radicans usually has 9–11 elliptically arranged leaves (each approx. 3 cm to 6 cm) on one stalked leaf [117]. The large number of relatively small leaves and the high plant density in the test favoured the drying out of the foliage. In addition, the plant had flowers at the time of the test. These flowers (approx. 4–12 in clusters), which typically appear in July to September [117], provide further fast-drying material. In the test, a several-centimetre wide strip next to the primary flame on the large side of the test stand burned abruptly as a “flare-up” over the total height at the 20th min. Due to the above-mentioned points, the heat release rate was proportionally higher here. However, it should be noted that in other tests, several flare-ups occurred at shorter intervals. A comparison of these peaks from Figs. 10, 11, 12, 13, 14, 15 and 16 shows that, in total, they corresponded to or even exceeded the peak heat release mentioned here.

The difference for W. sinensis (No. 35 according to Table 2) in relation to the overall course in comparison to the other plants can be explained by the higher mass, as shown in Table 2. The remarkably higher mass can be explained by several circumstances. Since a large amount of material was available, the mass proportion was increased here to investigate the influence on the heat release rate. However, an intensive but realistic plant density was chosen. Due to the small leaf size and the flowering time, a relatively large mass of plant material results in intensive vegetation. Wisteria sinensis usually has 7–12 ovate-elliptic arranged leaves (each approx. 5 cm to 8 cm) on one stalked leaf [117]. Towards the end of July, about 10 cm long seed pods develop from the 10 cm to 30 cm long flowers of W. sinensis. Inside the pods are seeds with a high protein content (lectins). The pods usually open in the following spring and distribute the seeds [117]. During the SBI tests, both flowers and seed pods were found on the W. sinensis. This is also obvious from the relatively high mass weight. The increased heat release rate can be explained by the burning of the dried flowers and seed pods.

5.3 Vital, Maintained Plants

In general, it can be stated that in all tests with vital, maintained plants, horizontal fire spread only occurred to a very small extent due to the flaming up of smaller dried-out parts that were directly next to the primary flame, as shown in Fig. 18. Consequently, significant horizontal fire spread is not to be expected in the case of vital, well-maintained plants in the context of a large-scale arrangement of plants on a façade.

All vital, maintained plants self-extinguished after the flame of the main burner was stopped. No further burning occurred during the observation period after the test.

5.4 Comparison Young vs. Old Plants

In the direct comparison of young and old plants, the basic findings from Sect. 1.4 were confirmed. While the older plants, which have a higher content of woody shoots, had a slightly higher heat release rate at the beginning, more flare-ups occurred for young plants in the process of the test. This can be explained by the larger amount of smaller leaves that dries out and burns off during the test, as shown in Fig. 20.

5.5 Role of Seasonal Influences

Another question was whether the seasonal influence of the plants had an effect on the fire behaviour in the context of a large-scale arrangement of plants on a façade. As shown in Figs. 21 and 22, a comparable trend was observed for the heat release rate. The tests carried out in winter with E. fortunei, H. helix, J. nudiflorum, and L. henryi were slightly higher at the beginning than the values of the specimens from the same plants in summer. For A. deliciosa, it must be taken into account that the plant had no foliage in winter, and therefore less material was present in the test. Here, the focus was on investigating the woody shoots. All in all, no substantial difference can be predicted in the context of a large-scale arrangement of plants on a façade with regard to the seasonal influence.

5.6 Dried Plants

A meaningful difference was found for the dried specimens. The specimens were dried for 42 days at ambient temperature and had a moisture content of 39% for young H. helix and 74% for Humulus lupulus. The difference in moisture content can be explained by the fact that young H. helix with small leaves dries significantly faster than H. lupulus, which also had a large number of hop cones. Overall, as shown in Figs. 23 and 24, there is a clear difference in the heat release rate. This is also evident from Fig. 17 and the total heat release.

The dried specimens, which are supposed to represent both dead plants and unmaintained plants with percentages of deadwood, show an abrupt heat release at the beginning in both cases. In the case of the dried H. helix, the entire test specimen burned within the first 5 min. In the case of H. lupulus, a large part burned. In both cases, unlike the vital specimens, there was rapid horizontal fire spread.

Comparing the heat release rate with those of a 13 mm chipboard and a 9 mm plywood board (SBI tests [80]) shows that the heat release peak of H. helix, in particular, exceeds that of the two above-mentioned construction products. However, it is important to note that the heat release of dry plants occurs abruptly over a few minutes. Consequently, there is no continuous heat release over the test period. This finding is substantial for further investigations in the context of a large-scale arrangement of plants on a façade, as the duration of a heat flow is critical for a possible ignition.

It is known from investigations that a heat flow five times higher is necessary for the ignition of wood, for example, when the impact occurs over a few minutes and not constant over a longer period of time [118]. It is also known that short-term fire exposure to modern multi-pane glazing does not usually cause all window panes to break [119]. The resulting question that needs to be investigated further is: How critical are short fire impacts from a green façade (including the scenario that a maintained plant with a small amount of deadwood becomes damaged and dried out) for an exterior wall, for the glazing or an open window and what role do they consequently play for fire spread along the exterior wall and into the building? It should be noted that climbing aids and trellises for green façades are usually at a distance of 8 cm to 20 cm from the outer wall, and consequently, fire spread does not occur directly along the outer wall [12].

Comparing the heat release rate of vital plants with those of chipboard or plywood, as shown in Figs. 23 and 24, it can be seen that vital plants provide a relatively low heat release rate even at high planting intensities.

5.7 Role of Essential Oils

The presence of essential oils in the respective plants was investigated in a literature search and is shown in Table 8 in the “Appendix”. It should be noted that this list does not claim to be exhaustive. With regard to the heat release rate, no substantial influence due to essential oils can be identified. This becomes particularly clear when considering the plants H. lupus and Lavandula angustifolia, which have a pronounced content of essential oils [120] but no substantial differences in heat release. However, when considering the smoke emission (SMOGRA value from Table 7 in the “Appendix”), it becomes obvious that the plants with essential oils contribute to more intensive smoke emission. With regard to external burning on the façade, this only plays a subordinate role.

6 Conclusion

In summary, only a little research is available internationally on the fire behaviour of green façades. Basically, green façades can be independently growing climbing plants on the outer wall or on climbing aids or trellises, or full wall-based systems, so-called living walls.

Living walls are complex systems with a rear-ventilated void cavity, supporting structure, cladding panels, substrate, fleece, irrigation system and the plants themselves. The systems differ significantly from one manufacturer to the next. Various manufacturers currently have initial findings from medium-scale fire tests on their living walls. However, some of these tests were not carried out with the entire system. From the authors’ point of view, these manufacturer-specific systems can only be meaningfully investigated for fire-safe use by means of large-scale tests on the entire respective system.

For this reason, the focus of the tests described here to determine the heat release of green façades was on climbing plants with climbing aids or trellises. The aim of the study was to investigate influences on the plant's flammability as basis for a future large-scale arrangement on a façade. The focus was on quantifying the influence of the plants in relation to the fire spread on a façade and not on the exact quantification of the flammability.

The main factor influencing the fire behaviour of plants is the moisture content. A comparison of the heat release rate of vital plants (normal moisture content) shows similar behaviour with a baseline of about 5 kW for these tests. In the course of the exposure, short peaks of the heat release rate occur. These peaks are “flare-ups” that occur when parts of the plants dry out due to the effect of the flame and then ignite and burn. The plant species itself has no substantial influence on fire behaviour. It was determined that in all tests with vital, maintained plants, horizontal fire spread occurred only to a very small extent and that all vital, maintained plants extinguished after the burner in the SBI tests was stopped. Also, in the direct comparison between young and old plants, as well as in the comparison of a seasonal influence, no substantial difference was determined for vital, maintained plants in the context of a large-scale arrangement of plants on a façade.

A decisive difference was found for dried plants. Here, an abrupt heat release occurred at the beginning. Dead plants, as well as unmaintained plants with a high content of deadwood, represent the most critical case. This leads to the conclusion that the care and maintenance of a green façade is the most important factor in maintaining fire safety. Dead wood in the form of dead foliage, branches or bird nests must be removed regularly. It must be checked at regular intervals whether the plants are still alive and therefore have a normal moisture content. In addition, it is important to ensure that the plants are regularly cut back. Uncontrolled growth can also lead to a lot of deadwood, especially in the case of light-fleeing plants.

7 Outlook

This research showed that the heat released from dry plants occurs suddenly over a few minutes. Consequently, there is no continuous heat release over a longer period of time.

The last two findings raise two important research questions for further investigation. On the one hand, the definition of proper care and maintenance is essential for a fire-safe green façade. What intervals are necessary, and at what point in time are the various maintenance measures required? It is already known from wildland fire research that the evaluation of the flammability of plants is quite complex [28]. It is known that there is no convenient or practical method to measure the moisture of living foliage in the field. An indication can be made by looking closely at the foliage and touching it [40]. Bright green, juicy foliage indicates high moisture levels, while brittle, cured, dry foliage that breaks in the hand is an alarm signal. The removal of deadwood is also a significant factor in forest fire safety [16, 21].

On the other hand, an important question that needs to be investigated further is what influence a very short-term heat flux has on the outer wall, windows and areas behind them, and what risk does this pose? A specific question would be, for example, whether the heat flux of a dead dry green façade (worst case) would be sufficient to ignite exterior wall cladding made of wood at a distance of a few centimetres.

In addition, it is necessary, in a further step, to examine the findings from the medium-scale tests on a full-scale basis and, in particular, to evaluate the vertical fire spread more specifically.

With regard to Sects. 1.4 and 2.1, the influence of wind on the fire behaviour of green façades should also be further investigated.

Overall, more research is needed to investigate the fire safety of green façades further. More information on living walls could be provided, for example, by the yet unpublished findings of the Instytut Techniki Budowlanej in Poland [121]. It is important to build up a solid database at this point in time. There are also already the first attempts to determine the fire spread along a green façade by means of a fire dynamics simulator model [122]. However, these results must be critically questioned at this point in time with regard to the database.

In a further phase of the FireSafeGreen research project, the focus is on the combination of wooden and green façades and the interactions on fire spread as well as fire tests on full-scale green façades. The full-scale fire tests are intended to provide further knowledge on vertical fire spread and its impact on the façade under realistic exposure scenarios. The results presented here are used to design the full-scale fire tests with green façades and to widen the full-scale tests results regarding its applicability. The results of the future full-scale tests should also be used to classify the findings from smaller standard fire tests (e.g. from Sect. 2.3) and to verify their applicability in practice. The objective is to create comparability of the findings from standardised test methods with real fire conditions on green façades. These results will be presented in Part 2.

References

United Nations: Department of Economic and Social Affairs Population Division (2019) World urbanization prospects the 2018 revision. United Nations, New York

Dahanayake KWDKC, Chow CL (2017) Studying the potential of energy saving through vertical greenery systems: using EnergyPlus simulation program. Energy Build 138:47–59. https://doi.org/10.1016/j.enbuild.2016.12.002

Perini K, Ottelé M, Fraaij ALA, Haas EM, Raiteri R (2011) Vertical greening systems and the effect on air flow and temperature on the building envelope. Build Environ 46:2287–2294. https://doi.org/10.1016/j.buildenv.2011.05.009

Pacini A, Edelmann HG, Großschedl J, Schlüter K (2022) A literature review on façade greening: how research findings may be used to promote sustainability and climate literacy in school. Sustainability 14(8):4596. https://doi.org/10.3390/su14084596

Eleftheria A, Phil J (2008) Temperature decreases in an urban canyon due to green walls and green roofs in diverse climates. Build Environ 43:480–493. https://doi.org/10.1016/j.buildenv.2006.10.055

Azkorra Z, Pérez G, Coma J, Cabeza LF, Bures S, Álvaro JE, Erkoreka A, Urrestarazu M (2015) Evaluation of green walls as a passive acoustic insulation system for buildings. Appl Acoust 89:46–56. https://doi.org/10.1016/j.apacoust.2014.09.010

Ottelé M, Perini K, Fraaij ALA, Haas EM, Raiteri R (2011) Comparative life cycle analysis for green façades and living wall systems. Energy Build 43:3419–3429. https://doi.org/10.1016/j.enbuild.2011.09.010

Pfoser N (2018) Vertikale Begrünung – Bauweisen und Planungsgrundlagen zur Begrünung von Wänden und Fassaden mit und ohne natürlichen Boden-/Bodenwasseranschluss. Eugen Ulmer KG, Stuttgart

Ogut O, Tzortzi NJ, Bertolin C (2022) Vertical green structures to establish sustainable built environment: a systematic market review. Sustainability 14:12349. https://doi.org/10.3390/su141912349

Brandwein T (2014) Statistisches über Brände mit Kletterpflanzen und Strategien zu ihrer Vermeidung. Brandschutz und Grün, Wien

Köhler M, Ansel W, Appl R, Betzler F, Mann G, Ottelé M, Wünschmann S (2012) Handbuch Bauwerksbegrünung Planung- Konstruktion. Rudolf Müller

Forschungsgesellschaft Landschaftsentwicklung Landschaftsbau e. V. (2018) Fassadenbegrünungsrichtlinien - Richtlinien für die Planung, Bau und Instandhaltung von Fassadenbegrünungen

Köhler M (1993) Fassaden- und Dachbegrünung. Ulmer Verlag

Babrauskas V (2003) Ignition Handbook—principles and applications to fire safety engineering, fire investigation, risk management and forensic science. Fire Science Publishers, Issaquah

Yamashita K (1986) Measurement of flaming ignition temperature of forest materials heated in hot air stream—comparison of coniferous tree and broadleaf tree. Kasai 36:12–18

Gill AM, Moore PHR (1996) Ignitibility of leaves of Australian plant. Centre for Plant Biodiversity Research, Canberra

White RH, Zipperer WC (2010) Testing and classification of individual plants for fire behaviour: plant selection for the wildland–urban interface. Int J Wildland Fire 19:213–227. https://doi.org/10.1071/WF07128

Babrauskas V, Chastagner G, Stauss E (2001) Flammability of cut Christmas trees. In: 2001 IAAI annual general meeting, 2001

Van Wagner CE (1963) Flammability of Christmas trees. Forest Research Branch, Department of Forestry Publication No. 1034, Ottawa

White RZ, DeMars D, Bishop M (1997) Flammability of Christmas trees and other vegetation. In: Proceedings of the 24th international conference on fire safety, 1997

Etlinger MG, Beall FC (2004) Development of a laboratory protocol for fire performance of landscape plants. Int J Wildland Fire 13:479–488. https://doi.org/10.1071/WF04039

Gallacher JR, Lansinger V, Hansen S, Weise DR, Fletcher TH (2015) Effects of season and heating mode on ignition and burning behavior of ten species of LIVE FUEL measured in a FLAT-flame burner system. In: AIChE annual meeting, 2015

Prince DR, Fletcher TH (2014) Differences in burning behavior of live and dead leaves—Part 1: measurements. Combust Sci Technol 186:1844–1857. https://doi.org/10.1080/00102202.2014.923412

Borujerdi PR, Shotorban B, Mahalingam S (2020) A computational study of burning of vertically oriented leaves with various fuel moisture contents by upward convective heating. Fuel. https://doi.org/10.1016/j.fuel.2020.118030

Albini FA (1979) Thermochemical properties of flame gases from fine wildland fuels. Research Paper INT-RP-243. U.S. Department of Agriculture, Forest Service, Intermountain Forest and Range Experiment Station

Livingston AC, Varner JM (2016) Fuel moisture differences in a mixed native and non-native grassland: implications for fire regimes. Fire Ecol 12:73–87. https://doi.org/10.4996/fireecology.1201073

Nelson RM (2001) Chapter 4—water relations of forest fuels. In: Forest fires. Academic. https://doi.org/10.1016/B978-012386660-8/50006-4

Dimitrakopoulos AP, Papaioannou KK (2001) Flammability assessment of Mediterranean forest fuels. Fire Technol 37(2):143–152. https://doi.org/10.1023/A:1011641601076

Viegas DX, Viegas MT, Ferreira AD (1992) Moisture content of fine forest fuels and fire occurrence in central Portugal. Int J Wildland Fire 2(2):69–86. https://doi.org/10.1071/WF9920069

Renkin R, Despain D (1992) Fuel moisture, forest type, and lightning-caused fire in Yellowstone National Park. Can J For Res 22(1):37–45. https://doi.org/10.1139/x92-005

Morandini F, Santoni PA, Tramoni JB, Mell WE (2019) Experimental investigation of flammability and numerical study of combustion of shrub of rockrose under severe drought conditions. Fire Saf J. https://doi.org/10.1016/j.firesaf.2019.102836

Anderson HE, Rothermel RC (1965) Influence of moisture and wind upon the characteristics of free-burning fires. In: Symposium (international) on combustion, 1965, vol 10, pp 1009–1019

Dahale A, Ferguson S, Shotorban B, Mahalingam S (2013) Effects of distribution of bulk density and moisture content on shrub fires. Int J Wildland Fire 22:625–641. https://doi.org/10.1071/WF12040

Jolly WM, Hadlow AM, Huguet K (2014) De-coupling seasonal changes in water content and dry matter to predict live conifer foliar moisture content. Int J Wildland Fire 23(4):480–489. https://doi.org/10.1071/wf13127

Agee JK, Wright CS, Williamson N, Huff MH (2002) Foliar moisture content of Pacific Northwest vegetation and its relation to wildland fire behavior. For Ecol Manag 167:57–66. https://doi.org/10.1016/S0378-1127(01)00690-9

Chrosciewicz Z (1986) Foliar moisture content variations in four coniferous tree species of central Alberta. Can J For Res 16:157–162. https://doi.org/10.1139/x86-029

Weise DR, White RH, Beall FC, Etlinger M (2005) Use of the cone calorimeter to detect seasonal differences in selected combustion characteristics of ornamental vegetation. Int J Wildland Fire 14:321–338. https://doi.org/10.1071/WF04035

Owens MK, Lin CD, Taylor CA, Whisenant SG (1998) Seasonal patterns of plant flammability and monoterpenoid content in Juniperus ashei. J Chem Ecol 24:2115–2129. https://doi.org/10.1023/A:1020793811615

Pellizzaro G, Duce P, Ventura A, Zara P (2007) Seasonal variations of live moisture content and ignitability in shrubs of the Mediterranean Basin. Int J Wildland Fire 16:633–641. https://doi.org/10.1071/WF05088

Schroeder MJ, Buck CC (1970) FIRE WEATHER: agriculture handbook 360. U.S. Department of Agriculture-Forest Service. https://www.nwcg.gov/publications/pms425-1

Madrigal J, Marino E, Guijarro M, Hernando C, Díez C (2012) Evaluation of the flammability of gorse (Ulex europaeus L.) managed by prescribed burning. Ann For Sci 69:387–397. https://doi.org/10.1007/s13595-011-0165-0

McAllister S, Weise DR (2017) Effects of season on ignition of live wildland fuels using the forced ignition and flame spread test apparatus. Combust Sci Technol 189:231–247. https://doi.org/10.1080/00102202.2016.1206086

Chuvieco E, Aguado I, Dimitrakopoulos AP (2004) Conversion of fuel moisture content values to ignition potential for integrated fire danger assessment. Can J For Res 34(11):2284–2293. https://doi.org/10.1139/x04-101

Sharples JJ, McRae RHD, Weber RO, Gill AM (2009) A simple index for assessing fuel moisture content. Environ Model Softw 24:637–646. https://doi.org/10.1016/j.envsoft.2008.10.012

Nunez-Regueira L, Rodriguez-Anon JA, Proupin J, Mourino B, Artiaga-Diaz R (2005) Energetic study of residual forest biomass using calorimetry and thermal analysis. J Therm Anal Calorim 80:457–464. https://doi.org/10.1007/s10973-005-0677-7

Pompe A, Vines RG (1966) The influence of moisture on the combustion of leaves. Aust For 30:231–241. https://doi.org/10.1080/00049158.1966.10675417

Zhao FJ, Shu LF, Wang MY, Tian XR (2013) Investigation of emissions from heated essential-oil-rich fuels at 200 °C. Fire Mater 37:391–400. https://doi.org/10.1002/fam.2140

European Standard (2002) Moisture content of a piece of sawn timber—Part 1: determination by oven dry method; German version EN 13183-1:2002

ASTM International (2020) Standard test methods for direct moisture content measurement of wood and wood-based materials, ASTM D4442-20. https://doi.org/10.1520/D4442-20

Rothermel RC (1983) How to predict the spread and intensity of forest and range fires. General Technical Report INT-143. USDA Forest Service, Intermountain Forest and Range Experiment Station

Scott JH, Burgan RE (2005) Standard fire behavior fuel models: a comprehensive set for use with Rothermel’s surface fire spread model. General Technical Report RMRS-GTR-153. U.S. Department of Agriculture, Forest Service, Rocky Mountain Research Station. https://doi.org/10.2737/RMRS-GTR-153

Borujerdi PR, Shotorban B, Mahalingam S, Weise DR (2019) Modeling of water evaporation from a shrinking moist biomass slab subject to heating: Arrhenius approach versus equilibrium approach. Int J Heat Mass Transf. https://doi.org/10.1016/j.ijheatmasstransfer.2019.118672

Pickett BM, Isackson C, Wunder R, Fletcher TH, Butler BW, Weise DR (2009) Flame interactions and burning characteristics of two live leaf samples; 1. Int J Wildland Fire 18:865–874. https://doi.org/10.1071/WF08143

Padhi S, Shotorban B, Mahalingam S (2017) A computational study of the interactions of three adjacent burning shrubs subjected to wind. Fire Saf J 91:749–757. https://doi.org/10.1016/j.firesaf.2017.03.028

Cole WJ, Dennis MH, Fletcher TH, Weise DR (2011) The effects of wind on the flame characteristics of individual leaves. Int J Wildland Fire 20:657–667. https://doi.org/10.1071/WF10019

Rahimi Borujerdi P, Shotorban B, Mahalingam S, Weise DR (2022) Influence of pyrolysis gas composition and reaction kinetics on leaf-scale fires. Combust Sci Technol 22:1–24. https://doi.org/10.1080/00102202.2022.2135995

Weise DR, Fletcher TH, Safdari M-S, Amini E, Palarea-Albaladejo J (2022) Application of compositional data analysis to determine the effects of heating mode, moisture status and plant species on pyrolysates. Int J Wildland Fire 31:24–45. https://doi.org/10.1071/WF20126

Safdari M-S, Amini E, Weise DR, Fletcher TH (2020) Comparison of pyrolysis of live wildland fuels heated by radiation vs. convection. Fuel 268:2–12. https://doi.org/10.1016/j.fuel.2020.117342

Safdari M-S, Amini E, Weise DR, Fletcher TH (2019) Heating rate and temperature effects on pyrolysis products from live wildland fuels. Fuel 242:295–304. https://doi.org/10.1016/j.fuel.2019.01.040

Safdari M-S, Rahmati M, Amini E, Howarth JE, Berryhill JP, Dietenberger M, Weise DR, Fletcher TH (2018) Characterization of pyrolysis products from fast pyrolysis of live and dead vegetation native to the Southern United States. Fuel 229:151–166. https://doi.org/10.1016/j.fuel.2018.04.166

Amini E, Safdari M-S, DeYoung JT, Weise DR, Fletcher TH (2019) Characterization of pyrolysis products from slow pyrolysis of live and dead vegetation native to the southern United States. Fuel 235:1475–1491. https://doi.org/10.1016/j.fuel.2018.08.112

Amini E, Safdari M-S, Johnson N, Weise DR, Fletcher TH (2021) Pyrolysis kinetics of wildland vegetation using model-fitting methods. J Anal Appl Pyrolysis. https://doi.org/10.1016/j.jaap.2021.105167

Amini E, Safdari M-S, Weise DR, Fletcher TH (2019) Pyrolysis kinetics of live and dead wildland vegetation from the Southern United States. J Anal Appl Pyrolysis. https://doi.org/10.1016/j.jaap.2019.05.002

Anand C, Shotorban B, Mahalingam S, McAllister S, Weise DR (2017) Physics-based modeling of live wildland fuel ignition experiments in the forced ignition and flame spread test apparatus. Combust Sci Technol 189:1551–1570. https://doi.org/10.1080/00102202.2017.1308357

Yashwanth BL, Shotorban B, Mahalingam S, Weise DR (2015) An investigation of the influence of heating modes on ignition and pyrolysis of woody wildland fuel. Combust Sci Technol 187:780–796. https://doi.org/10.1080/00102202.2014.973948

Dietenberger MA, Boardman CR, Shotorban B, Mell W, Weise DR (2020) Thermal degradation modeling of live vegetation for fire dynamic simulator. In: Proceedings, 2020 spring technical meeting, 2020. Central States Section of the Combustion Institute

Matt FJ, Dietenberger MA, Weise DR (2020) Summative and ultimate analysis of live leaves from southern U.S. forest plants for use in fire modeling. Energy Fuels 34:4703–4720. https://doi.org/10.1021/acs.energyfuels.9b04107

Pickett BM, Isackson C, Wunder R, Fletcher TH, Butler BW, Weise DR (2010) Experimental measurements during combustion of moist individual foliage samples. Int J Wildland Fire 19:153–162. https://doi.org/10.1071/WF07121

Ferguson SC, Dahale A, Shotorban B, Mahalingam S, Weise DR (2013) The role of moisture on combustion of pyrolysis gases in wildland fires. Combust Sci Technol 185:435–453. https://doi.org/10.1080/00102202.2012.726666

Engstrom JD, Butler JK, Smith SG, Baxter LL, Fletcher TH, Weise DR (2004) Ignition behavior of live California chaparral leaves. Combust Sci Technol 176:1577–1591. https://doi.org/10.1080/00102200490474278

Fletcher TH, Pickett BM, Smith SG, Spittle GS, Woodhouse MM, Haake E, Weise DR (2007) Effects of moisture on ignition behavior of moist California chaparral and Utah leaves. Combust Sci Technol 179:1183–1203. https://doi.org/10.1080/00102200601015574

Shotorban B, Yashwanth BL, Mahalingam S, Haring DJ (2018) An investigation of pyrolysis and ignition of moist leaf-like fuel subject to convective heating. Combust Flame 190:25–35. https://doi.org/10.1016/j.combustflame.2017.11.008

Cobian-Iñiguez J, Aminfar AH, Saha S, Awayan K, Weise DR, Princevac M (2022) The transition and spread of a chaparral crown fire: insights from laboratory scale wind tunnel experiments. J Combust. https://doi.org/10.1155/2022/5630594