Abstract

This study provides extensive information regarding the resistance of the material to maintain its properties under dynamic loading conditions. The effects of dynamic loading conditions on PLA reinforced with various fibers produced via the material extrusion were investigated. Specifically, it examined the material's response to an increase in the number of shock impacts in comparison to the control specimen. X-ray diffraction analysis and Raman spectroscopy were employed to validate the material's amorphous composition and crystallinity. The morphological alterations were illustrated using scanning electron microscopy images and digital microscopic images. Carbon fiber-reinforced PLA demonstrated superior resistance to phase transitions under impact loading conditions compared to other materials. The agreement between the x-ray diffraction and Raman spectroscopy results confirms the material's reliability under dynamic loading conditions. The phases of pure PLA and PLA-GF remained unchanged until 50 shocks, at which point their crystallinity transformed into an amorphous state. The PLA-CF did not exhibit any phase alterations until 150 shocks. The tensile strength of the specimens is assessed following 50 shock exposure cycles, revealing a notable decrease in the tensile strength of PLA and PLA-GF. In contrast, PLA-CF exhibits only a slight decline, due to its improved resistance to phase change.

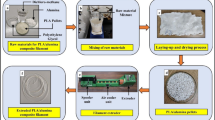

Graphical Abstract

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available in public and can be shared by the corresponding author on request.

References

P. Wady, A. Wasilewski, L. Brock, R. Edge, A. Baidak, C. McBride, L. Leay, A. Griffiths, and C. Vallés, Effect of Ionising Radiation on the Mechanical and Structural Properties of 3D Printed Plastics, Addit. Manuf., 2019, 2020(31), p 100907. https://doi.org/10.1016/j.addma.2019.100907

Y. Lyu, Y. Chen, Z. Lin, J. Zhang, and X. Shi, Manipulating Phase Structure of Biodegradable PLA/PBAT System: Effects on Dynamic Rheological Responses and 3D Printing, Compos. Sci. Technol., 2020, 200, p 108399. https://doi.org/10.1016/j.compscitech.2020.108399

Y. Liu, W. Zhang, F. Zhang, J. Leng, S. Pei, L. Wang, X. Jia, C. Cotton, B. Sun, and T.W. Chou, Microstructural Design for Enhanced Shape Memory Behavior of 4D Printed Composites Based on Carbon Nanotube/Polylactic Acid Filament, Compos. Sci. Technol., 2019, 181, p 107692. https://doi.org/10.1016/j.compscitech.2019.107692

Y. Liao, C. Liu, B. Coppola, G. Barra, L. Di Maio, L. Incarnato, and K. Lafdi, Effect of Porosity and Crystallinity on 3D Printed PLA Properties, Polymers (Basel), 2019, 11(9), p 1–14.

R. Baptista, M. Guedes, M.F.C. Pereira, A. Maurício, H. Carrelo, and T. Cidade, On the Effect of Design and Fabrication Parameters on Mechanical Performance of 3D Printed PLA Scaffolds, Bioprinting, 2020, 20, p e00096. https://doi.org/10.1016/j.bprint.2020.e00096

R. Aziz, M.I. Ul Haq, and A. Raina, Effect of Surface Texturing on Friction Behaviour of 3D Printed Polylactic Acid (PLA), Polym. Test., 2020, 85, p 106434. https://doi.org/10.1016/j.polymertesting.2020.106434

N. Naveed, Investigate the Effects of Process Parameters on Material Properties and Microstructural Changes of 3D-Printed Specimens Using Fused Deposition Modelling (FDM), Mater. Technol., 2021, 36(5), p 317–330. https://doi.org/10.1080/10667857.2020.1758475

K. Wang, H. Long, Y. Chen, M. Baniassadi, Y. Rao, and Y. Peng, Heat-Treatment Effects on Dimensional Stability and Mechanical Properties of 3D Printed Continuous Carbon Fiber-Reinforced Composites, Compos. Part A Appl. Sci. Manuf., 2021, 147, p 106460. https://doi.org/10.1016/j.compositesa.2021.106460

S. Guessasma, S. Belhabib, and H. Nouri, Microstructure and Mechanical Performance of 3D Printed Wood-PLA/PHA Using Fused Deposition Modelling: Effect of Printing Temperature, Polymers (Basel), 2019, 11(11), p 1778.

X. Zhou, J. Deng, C. Fang, W. Lei, Y. Song, Z. Zhang, Z. Huang, and Y. Li, Additive Manufacturing of CNTs/PLA Composites and the Correlation between Microstructure and Functional Properties, J. Mater. Sci. Technol., 2021, 60, p 27–34. https://doi.org/10.1016/j.jmst.2020.04.038

T. Batakliev, V. Georgiev, C. Kalupgian, P.A.R. Muñoz, H. Ribeiro, G.J.M. Fechine, R.J.E. Andrade, E. Ivanov, and R. Kotsilkova, Physico-Chemical Characterization of PLA-Based Composites Holding Carbon Nanofillers, Appl. Compos. Mater., 2021, 28(4), p 1175–1192. https://doi.org/10.1007/s10443-021-09911-0

W. Yu, X. Wang, E. Ferraris, and J. Zhang, Melt Crystallization of PLA/Talc in Fused Filament Fabrication, Mater. Des., 2019, 182, p 108013. https://doi.org/10.1016/j.matdes.2019.108013

V. Mochalova, A. Utkin, V. Sosikov, V. Yakushev, and A. Zhukov, Shock Wave Response of Porous Carbon Fiber-Epoxy Composite, Shock Waves, 2022, 32(8), p 715–725. https://doi.org/10.1007/s00193-022-01104-3

A. Sivakumar, S.S.J. Dhas, L. Dai, V. Mowlika, P. Sivaprakash, R.S. Kumar, A.I. Almansour, S. Arumugam, I. Kim, and S.A.M.B. Dhas, X-Ray Diffraction and Optical Spectroscopic Analysis on the Crystallographic Phase Stability of Shock Wave Loaded L-Valine, J. Mater. Sci., 2023, 58(22), p 9210–9220. https://doi.org/10.1007/s10853-023-08588-z

A. Sivakumar, S. Kalaiarasi, S. Sahaya Jude Dhas, P. Sivaprakash, S. Arumugam, M. Jose, and S.A. Martin Britto Dhas, Comparative Assessment of Crystallographic Phase Stability of Anatase and Rutile TiO2 at Dynamic Shock Wave Loaded Conditions, J. Inorg. Organomet. Polym. Mater., 2022, 32(3), p 967–972.

M.M. Dharmaraj, B.C. Chakraborty, and S. Begum, The Effect of Graphene and Nanoclay on Properties of Nitrile Rubber/Polyvinyl Chloride Blend with a Potential Approach in Shock and Vibration Damping Applications, Iran, Polym. J. English Ed., 2022, 31(9), p 1129–1145. https://doi.org/10.1007/s13726-022-01064-6

A.D. Resnyansky, S.A. Weckert, and T.E. Dalby, Influence of Strength and Thermo-Mechanical Properties of Solid Constituents on Temperature of Two Shock Loaded Porous Materials, J. Dyn. Behav. Mater., 2020, 6(1), p 1–13. https://doi.org/10.1007/s40870-019-00222-x

R.C. Huber, E.B. Watkins, J.L. Jordan, D.M. Dattelbaum, E.N. Brown, B.D. Bartram, and L.L. Gibson, Capturing Polymer Chain Compression and Shock Driven Decomposition of Polytetrafluoroethylene During Dynamic Shock Compression with In Situ X-Ray Diffraction, J. Dyn. Behav. Mater., 2023 https://doi.org/10.1007/s40870-023-00391-w

K. Arunprasath, M. Vijayakumar, M. Ramarao, T.G. Arul, S.P. Pauldoss, M. Selwin, B. Radhakrishnan, and V. Manikandan, Dynamic Mechanical Analysis Performance of Pure 3D Printed Polylactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS), Mater. Today Proc., 2021, 50, p 1559–1562. https://doi.org/10.1016/j.matpr.2021.09.113

B. Suresha, V.V. Giraddi, A. Anand, and H.M. Somashekar, Dynamic Mechanical Analysis of 3D Printed Carbon Fiber Reinforced Polylactic Acid Composites, Mater. Today Proc., 2022, 59, p 794–799. https://doi.org/10.1016/j.matpr.2022.01.035

M.A. Goorabi and M. Heuzey, Titre: Recycling of Fibreglass Wind Turbine Blades Into Reinforced PLA, 2021.

G.S. Sivagnanamani, S.R. Begum, R. Siva, and M.S. Kumar, Experimental Investigation on Influence of Waste Egg Shell Particles on Polylactic Acid Matrix for Additive Manufacturing Application, J. Mater. Eng. Perform., 2022, 31(5), p 3471–3480. https://doi.org/10.1007/s11665-021-06464-y

K.R. Kumar, V. Mohanavel, and K. Kiran, Mechanical Properties and Characterization of Polylactic Acid/Carbon Fiber Composite Fabricated by Fused Deposition Modeling, J. Mater. Eng. Perform., 2022, 31(6), p 4877–4886. https://doi.org/10.1007/s11665-021-06566-7

A.A. Ansari and M. Kamil, Performance Study of 3D Printed Continuous Fiber-Reinforced Polymer Composites Using Taguchi Method, J. Mater. Eng. Perform., 2023, 32(21), p 9892–9906. https://doi.org/10.1007/s11665-022-07715-2

A. Shrivastava, J.S. Chohan, and R. Kumar, On Mechanical, Morphological, and Fracture Properties of Sustainable Composite Structure Prepared by Materials Extrusion-Based 3D Printing, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08593-y

E. Rezvani Ghomi, F. Khosravi, A. SaediArdahaei, Y. Dai, R.E. Neisiany, F. Foroughi, M. Wu, O. Das, and S. Ramakrishna, The Life Cycle Assessment for Polylactic Acid (PLA) to Make It a Low-Carbon Material, Polymers (Basel), 2021, 13(11), p 1–16.

S.W. Ahmed, G. Hussain, K. Altaf, S. Ali, M. Alkahtani, M.H. Abidi, and A. Alzabidi, On the Effects of Process Parameters and Optimization of Interlaminate Bond Strength in 3D Printed ABS / CF-PLA Composite, Polymers (Basel), 2020, 12, p 2155.

H. Hasdiansah, R.I. Yaqin, P. Pristiansyah, M.L. Umar, and B.H. Priyambodo, FDM-3D Printing Parameter Optimization Using Taguchi Approach on Surface Roughness of Thermoplastic Polyurethane Parts, Int. J. Interact. Des. Manuf., 2023, 17(6), p 3011–3024. https://doi.org/10.1007/s12008-023-01304-w

M.M. Tünçay, An Investigation of 3D Printing Parameters on Tensile Strength of PLA Using Response Surface Method, J. Mater. Eng. Perform., 2023, (Ref 23).

G. Sakthi Balan and S. Aravind Raj, A Review on Shock Tubes with Multitudinous Applications, Int. J. Impact Eng, 2023, 172, p 104406. https://doi.org/10.1016/j.ijimpeng.2022.104406

A. Sivakumar, S. Balachandar, and S.A.M.B. Dhas, Measurement of “ Shock Wave Parameters ” in a Novel Table-Top Shock Tube Using Microphones, Human Factors and Mechanical Engineering for Defense and Safety, 2020, 5, p 4–9.

A. Rita, A. Sivakumar, and S.A. Martin Britto Dhas, Influence of Shock Waves on Structural and Morphological Properties of Copper Oxide NPs for Aerospace Applications, J. Nanostructure Chem., 2019, 9(3), p 225–230. https://doi.org/10.1007/s40097-019-00313-0

K.P.J. Reddy and N. Sharath, Manually Operated Piston-Driven Shock Tube, Curr. Sci., 2013, 104(2), p 172–176.

R.C. Huber, E.B. Watkins, D.M. Dattelbaum, B.D. Bartram, L.L. Gibson, and R.L. Gustavsen, In Situ X-Ray Diffraction of High Density Polyethylene during Dynamic Drive: Polymer Chain Compression and Decomposition, J. Appl. Phys., 2021, 130(17).

A. Sivakumar, L. Dai, S.S.J. Dhas, S.A.M.B. Dhas, V. Mowlika, R.S. Kumar, and A.I. Almansour, Reduction of Amorphous Carbon Clusters from the Highly Disordered and Reduced Graphene Oxide NPs by Acoustical Shock Waves — Towards the Formation of Highly Ordered Graphene, Diam. Relat. Mater., 2023, 137, p 110139. https://doi.org/10.1016/j.diamond.2023.110139

A. Sivakumar, P. Eniya, S.S.J. Dhas, L. Dai, R.S. Kumar, A.I. Almansour, A. Sakthisabarimoorthi, J.K. Sundar, and S.A.M.B. Dhas, Assessment of Shock Wave Assisted Crystallographic Structural Stability of Poly-Crystalline and Single Crystalline Lithium Sulfate Monohydrate Crystals, J. Mol. Struct., 2023, 1288, p 135699. https://doi.org/10.1016/j.molstruc.2023.135699

A. Sivakumar, S.S.J. Dhas, A.I. Almansour, R.S. Kumar, N. Arumugam, K. Perumal, and S.A.M.B. Dhas, Sustainability of the Crystallographic Phase Stability of the Barium Carbonate Nanoparticles at Dynamic Shocked Conditions, Appl. Phys. A Mater. Sci. Process., 2021, 127(12), p 1–7. https://doi.org/10.1007/s00339-021-05059-7

A. Sivakumar, S. Sahaya Jude Dhas, J. Elberin Mary Theras, M. Jose, P. Sivaprakash, S. Arumugam, and S.A. Martin Britto Dhas, Spectroscopic and Diffraction Studies of Polycrystalline Copper Sulfate Pentahydrate at Shocked Conditions, Solid State Sci., 2021, 121, p 106751. https://doi.org/10.1016/j.solidstatesciences.2021.106751

A. Sivakumar, S.S. Jude Dhas, S. Chakraborty, R.S. Kumar, A.I. Almansour, N. Arumugam, and S.A.M.B. Dhas, Dynamic Shock Wave-Induced Amorphous-to-Crystalline Switchable Phase Transition of Lithium Sulfate, J. Phys. Chem. C, 2022, 126(6), p 3194–3201.

A. Sivakumar, A. Rita, S. Sahaya Jude Dhas, K.P.J. Reddy, R.S. Kumar, A.I. Almansour, S. Chakraborty, K. Moovendaran, J. Sridhar, and S.A. Martin Britto Dhas, Dynamic Shock Wave Driven Simultaneous Crystallographic and Molecular Switching between α-Fe2O3 and Fe3O4 Nanoparticles: A New Finding, Dalt. Trans., 2022, 51(23), p 9159–9166.

A. Sivakumar, S.S.J. Dhas, A.I. Almansour, R.S. Kumar, N. Arumugam, and S.A.M.B. Dhas, Spectroscopic Assessment of Shock Wave Resistance on ZnO Nanorods for Aerospace Applications, J. Inorg. Organomet. Polym. Mater., 2021, 31(6), p 2553–2559. https://doi.org/10.1007/s10904-020-01848-4

A. Sivakumar, P. Eniya, S.S.J. Dhas, R.S. Kumar, A.I. Almansour, S. Chakraborty, and J.K. Sundar, Comparative Analysis of Crystallographic Phase Stability of Single and Poly-Crystalline Lead Nitrate at Dynamic Shocked Conditions, 2022, p 1–18.

A. Sivakumar, S.S.J. Dhas, L. Dai, J. Thirupathy, K. Sethuraman, R.S. Kumar, A.I. Almansour, N. Vijayan, and S.A.M.B. Dhas, Dynamic Shock Wave-Induced Switchable Order to Disorder States of Single Crystal of Sulfamic Acid: A Combined Study of X-Ray and Raman Spectroscopy, J. Mater. Sci., 2023, 58(20), p 8415–8425. https://doi.org/10.1007/s10853-023-08532-1

B. Ma, X. Wang, Y. He, Z. Dong, X. Zhang, X. Chen, and T. Liu, Effect of Poly(Lactic Acid) Crystallization on Its Mechanical and Heat Resistance Performances, Polymer (Guildf), Elsevier Ltd, 2020, 2021(212), p 1–9.

C. Zhou, H. Li, W. Zhang, J. Li, S. Huang, Y. Meng, J. De Claville Christiansen, D. Yu, Z. Wu, and S. Jiang, Thermal Strain-Induced Cold Crystallization of Amorphous Poly(Lactic Acid), CrystEngComm, 2016, 18(18), p 3237–3246.

A. Sivakumar, L. Dai, S.J. Dhas, R.S. Kumar, A.I. Almansour, and S.B. Dhas, Tuning of Lower to Higher Crystalline Nature of β-L-Glutamic Acid by Shock Waves, J. Mol. Struct., 2023, 1288, p 135788. https://doi.org/10.1016/j.molstruc.2023.135788

A. Sivakumar, S.S. Jude Dhas, T. Pazhanivel, A.I. Almansour, R.S. Kumar, N. Arumugam, C.J. Raj, and S.A.M.B. Dhas, Phase Transformation of Amorphous to Crystalline of Multiwall Carbon Nanotubes by Shock Waves, Cryst. Growth Des., 2021, 21(3), p 1617–1624.

A. Sivakumar, A. Saranraj, S.S.J. Dhas, T. Vasanthi, V.N. Vijayakumar, P. Sivaprakash, V. Pushpanathan, S. Arumugam, L. Dai and, S.A.M.B. Dhas, Shock Wave Recovery Experiments on Poly-Crystalline Tri-Glycine Sulfate: X- Ray and Raman Analyses, J. Mol. Struct., 2023, 1283, p 135262. https://doi.org/10.1016/j.molstruc.2023.135262

D.M. Dattelbaum, J.D. Coe, P.A. Rigg, R.J. Scharff, and J.T. Gammel, Shockwave Response of Two Carbon Fiber-Polymer Composites to 50 GPa, J. Appl. Phys., 2014 https://doi.org/10.1063/1.4898313

A. Dhiman, N.S. Lewis, A. Olokun, D.D. Dlott, and V. Tomar, Thermo-Mechanical Behavior Measurement of Polymer-Bonded Sugar under Shock Compression Using in-Situ Time-Resolved Raman Spectroscopy, Sci. Rep., 2022, 12(1), p 1–9. https://doi.org/10.1038/s41598-022-05834-3

P. ASTM International, West Conshohocken, ASTM D638-14, Standard Test Method for Tensile Properties of Plastics, 2014, https://doi.org/10.1520/D0638-14.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sakthi Balan, G., Aravind Raj, S. Sustainability of Existing Phase of Extruded Fiber-Reinforced Polylactic Acid under Dynamic Shock Loading Conditions. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09472-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09472-w