Abstract

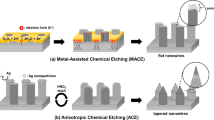

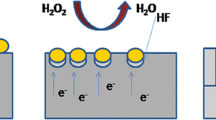

The process of texturing silicon surfaces is critical for enhancing the performance of complementary metal–oxide–semiconductor image sensors that utilize silicon-based photodetectors. Traditional wet etching methods using strong acids or alkaline solutions have been commonly used but present challenges in precision, particularly for microscopic devices. As a viable alternative, dry etching processes using patterned metals and plasma are being explored. However, extensive studies across various metals are necessary. This study introduces a silicon nanotexturing process using silver nanowires and Cl2-based plasma. The etching mechanism involves accelerated etching through eddy currents and hole injection coupled with a diffusion phenomenon of silver. In this study, we examined variations in the etching profile with respect to etching time, upper and bottom radio-frequency powers, and process pressure. Additionally, we analyzed the effects of ion bombardment, enhanced by the introduction of Ar gas. The findings are expected to significantly contribute to the improvement of micro-optoelectronic devices.

Similar content being viewed by others

Data Availability

No datasets were generated or analysed during the current study.

References

Oike Y (2021) Evolution of image sensor architectures with stacked device technologies. IEEE Trans Electron Devices 69(6):2757–2765

Nomoto T, Oike Y, Wakabayashi H (2016) Accelerating the sensing world through imaging evolution. in 2016 IEEE Symposium on VLSI Circuits (VLSI-Circuits). IEEE

Yokogawa S et al (2017) IR sensitivity enhancement of CMOS Image Sensor with diffractive light trapping pixels. Sci Rep 7(1):3832

Tian L et al (2017) Enhanced CMOS image sensor by flexible 3D nanocone anti-reflection film. Sci Bull 62(2):130–135

Li W, Valentine JG (2017) Harvesting the loss: surface plasmon-based hot electron photodetection. Nanophotonics 6(1):177–191

Sobhani A et al (2013) Narrowband photodetection in the near-infrared with a plasmon-induced hot electron device. Nat Commun 4(1):1643

Hsu T-H et al (2004) Light guide for pixel crosstalk improvement in deep Submicron CMOS image sensor. IEEE Electron Device Lett 25(1):22–24

Sekine H et al (2017) Development of gentle slope light guide structure in a 3.4 µm Pixel Pitch global shutter CMOS image sensor with multiple accumulation shutter technology. Sensors 17(12):2860

Fesenmaier CC, Huo Y, Catrysse PB (2008) Optical confinement methods for continued scaling of CMOS image sensor pixels. Opt Express 16(25):20457–20470

Kim MS, Lee JH, Kwak MK (2020) Surface texturing methods for solar cell efficiency enhancement. Int J Precis Eng Manuf 21:1389–1398

Xu M et al (2023) Surface Engineering in SnO2/Si for High-Performance Broadband Photodetectors. ACS Appl Mater Interfaces 15(2):3664–3672

Szlufcik J et al (1997) Low-cost industrial technologies of crystalline silicon solar cells. Proc IEEE 85(5):711–730

Vazsonyi E et al (1999) Improved anisotropic etching process for industrial texturing of silicon solar cells. Sol Energy Mater Sol Cells 57(2):179–188

Singh P et al (2001) Effectiveness of anisotropic etching of silicon in aqueous alkaline solutions. Sol Energy Mater Sol Cells 70(1):103–113

Zhang D et al (2022) Improving the performance of PERC silicon solar cells by optimizing the surface inverted pyramid structure on large-area mono-crystalline silicon wafers. Mater Sci Semiconduct Process 138:106281

Stapf A et al (2017) Texturing of monocrystalline silicon wafers by HF-HCl-H2O2 mixtures: generation of random inverted pyramids and simulation of light trapping in PERC solar cells. Sol Energy Mater Sol Cells 159:112–120

Dai X et al (2018) The influence of surface structure on diffusion and passivation in multicrystalline silicon solar cells textured by metal assisted chemical etching (MACE) method. Sol Energy Mater Sol Cells 186:42–49

Sreejith K et al (2021) A comprehensive investigation of the potential of metal assisted chemical etched (MACE) nano-textures over conventional micron-sized iso-textures for industrial silicon solar cell applications. Sol Energy 230:874–882

Pera DM et al (2023) Development of a metal-assisted chemical etching method to improve light-capture in monocrystalline silicon solar cells. Sol Energy Mater Sol Cells 251:112143

Omer A-A-A et al (2020) Nano-texturing of silicon wafers via one-step copper-assisted chemical etching. Silicon 12:231–238

Huang Z et al (2010) Metal-assisted electrochemical etching of silicon. Nanotechnology 21(46):465301

James T et al (2010) A one-step etching method to produce gold nanoparticle coated silicon microwells and microchannels. Anal Bioanal Chem 398:2949–2954

James T et al (2012) Voltage-gated ion transport through semiconducting conical nanopores formed by metal nanoparticle-assisted plasma etching. Nano Lett 12(7):3437–3442

Sun JB, Almquist BD (2018) Interfacial contact is required for metal-assisted plasma etching of Silicon. Adv Mater Interfaces 5(24):1800836

Lee D-G et al (2024) Nanohole texturing to improve the performance of a microscopic photodetector. Mater Sci Semiconduct Process 169:107915

Jansen H et al (1995) The black silicon method II: the effect of mask material and loading on the reactive ion etching of deep silicon trenches. Microelectron Eng 27(1–4):475–480

Dey RK, Ekinci H, Cui B (2020) Effects of mask material conductivity on lateral undercut etching in silicon nano-pillar fabrication. J Vacuum Sci Technol B, 38(1)

Kolasinski KW (2014) The mechanism of galvanic/metal-assisted etching of silicon. Nanoscale Res Lett 9:1–8

Lee Y-J et al (2003) Characteristics of Ag etching using inductively coupled Cl2-based plasmas. Jpn J Appl Phys 42(1R):286

Sasaki T et al (2020) Silver film etching using halogen gas plasma. J Vacuum Sci Technol A, 38(5)

Green T (2014) Gold etching for microfabrication. Gold Bull 47(3):205–216

Kang TY et al (2009) Process optimization of CF4/Ar plasma etching of au using I-optimal design. Thin Solid Films 517(14):3919–3922

Choi T-S, Levitin G, Hess DW (2013) Mechanistic considerations in plasma-assisted etching of ag and au thin films. ECS J Solid State Sci Technol 2(6):P275

Yin Y-H, Zhang L (2016) The structures and properties of (AgCl) n (n = 2–13). Comput Theor Chem 1097:70–78

Zhang L et al (2020) High-density plasma etching characteristics of aluminum-doped zinc oxide thin films in Cl2/Ar plasma. Mater Res Express 7(10):106301

Efremov A et al (2007) Self-consistent global model for inductively coupled Cl2 plasma: comparison with experimental data and application for the etch process analysis. Thin Solid Films 515(13):5395–5402

Raja LL, Linne M (2002) Analytical model for ion angular distribution functions at rf biased surfaces with collisionless plasma sheaths. J Appl Phys 93:7032–7040

Acknowledgements

This work was supported by Korea Institute for Advancement of Technology (KIAT) grant funded by the Korea Government (MOTIE) (P0023718, Inorganic Light-emitting Display Expert Training Program for Display Technology Transition), “Regional Innovation Strategy (RIS)” through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (MOE) (2023RIS-009) and the Institute for Basic Science (IBS-R019-Y1).

Author information

Authors and Affiliations

Contributions

Dong-Geon Lee: Conceptualization, Validation, Formal analysis, Investigation, Data Curation, Visualization, Writing - original draft. Hyun-Seung Ryu: Validation, Investigation. Mi-Jin Jin: Conceptualization, Methodology, Resources, Writing - Review & Editing. Doo-Seung Um: Conceptualization, Methodology, Resources, Visualization, Writing - Review & Editing, Supervision, Funding acquisition. Chang-Il Kim: Conceptualization, Writing - Review & Editing, Supervision, Project administration, funding acquisition.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lee, DG., Ryu, HS., Jin, MJ. et al. Diverse Texturing Characteristics Through Metal-Assisted Plasma Etching with Silver Nanowires. Plasma Chem Plasma Process (2024). https://doi.org/10.1007/s11090-024-10469-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11090-024-10469-5