Abstract

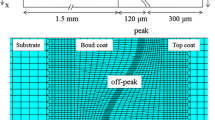

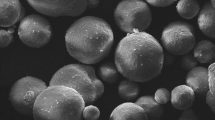

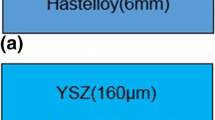

In order to study the influence of the bond coat on the erosion resistance of the thermal barrier coating (TBC), two different bond coats (NiCrAlY and NiCoCrAY) were deposited onto Inconel 718 substrate by using Atmospheric Plasma Spray (APS). After that topcoat Yttria Stabilized Zirconia with the Y2O3 content of 8 weight % (8YSZ) coatings were deposited by APS method onto the bond coats also. Alternative test rig compliant with the ASTM G211-14, was used in experiments. These experiments were performed at three different air temperatures (21°C, 300°C and 600°C), three different erosive particle impact angles (30°, 60° and 90°), constant particle impact velocity (~97 m/s) and particle size (400 µm Al2O3) after which, the erosion rate-impact angles results were obtained. Scanning electron microscopy (SEM) images, X-ray diffraction (XRD) analysis, Energy dispersive X-ray (EDX) mapping and EDX elemental analysis were conducted to assess the effectiveness of bond coating and ceramic topcoats to reduce wear at high temperatures. The importance of adhesion at the interface between bond coatings and ceramic topcoats was determined. However, erosion resistance generally increased with temperature, and this resistance effect tended to decrease with the presence of Cobalt.

Similar content being viewed by others

References

Peter J 2013 Modern gas turbine systems: high efficiency, low emission, fuel flexible power generation. Elsevier

Masao I, Masashi T, Toyoaki K and Jun Y 2008 Development of high efficiency gas turbine combined cycle power plant, Mitsubishi Technical Reviev V45 Nr1

Musa D and Mehmet B 2021 High temperature solid particle erosion comparison of atmospheric plasma sprayed MCrAlY coatings. Surface Topograph. Metrol. Properties 9: 035007

Dipak K and Pandey K N 2021 A comparative study of erosion wear rate of conventional and nonconventional thermal barrier coatings on IN800 superalloys. Sādhanā 46: 1–17

Dipak K, Vijay K D and Amit S 2022 Performance of 2024 aluminum alloy thermal barrier coating systems subjected to elevated temperature fluctuation as a fatigue. Sādhanā 47: 216

Federico C, Lorenzo L, Stefano C, Cristina G, Matthias K, Robert V, Konstantin V N, Nicolaie M, Justine M and Carlo G 2011 Solid particle erosion of thermal spray and physical vapour deposition thermal barrier coatings. Wear 271: 2909–2918

Federico C, Cristina G, Stefano C, Lorenzo L, Daniel Emil M and Alessandro M 2016 Solid particle erosion of standard and advanced thermal barrier coatings. Wear 348: 43–51

Rohan S, Awatef H, Dongyun S, Nathanial W and Robert M 2012 Deterioration of thermal barrier coated turbine blades by erosion, International Journal of Rotating Machinery, 2012

Dongyun S and Awatef H 2018 Influence of micro–structure on erosion resistance of plasma sprayed 7YSZ thermal barrier coating under gas turbine operating conditions. Wear 396: 34–47

ASTM International 2014 Standard Test Method for Conducting Elevated Temperature Erosion Tests by Solid Particle Impingement Using Gas Jets: Designation: G211-14. ASTM International

Ekrem A 2011 Manufacturing, characterizaton of YSZ and CSZ based thermal barrier coatings and comparison of the thermal cycling performance, PhD Thesis, Sakarya university institute of science, Sakarya

Weijie C, Xijia W, Basil R M, Douglas R N and Prakash C P 2008 TGO growth behaviour in TBCs with APS and HVOF bond coats. Surface Coat. Technol. 202: 2677–2683

ASTM Standard 2012 E18-12: Standard test methods for Rockwell hardness of metallic materials, ASTM International, West Conshohocken, PA

Emine B 2015 Yttria-Stabilized Zirconia/Gadolinium Zirconate Double-Layer Plasma-Sprayed Thermal Barrier Coating Systems (TBCs), PhD Thesis, Forschungszentrum Jülich GmbH Zentralbibliothek, Verlag Jülich

Federico C, Igor O G, Paolo Giulio B, Alessandro M, Robert V, Hans Peter B and Stefano C 2013 Microstructural characterization of porous thermal barrier coatings by IR gas porosimetry and sintering forecasts. Acta Mater. 61: 248–262

Mikijelj B and Varela J 1991 Equivalence of surface areas determined by nitrogen adsorption and by mercury porosimetry. Am. Ceram. Soc. Bull. 70: 829–831

Sidney D 2000 Mercury porosimetry: an inappropriate method for the measurement of pore size distributions in cement-based materials. Cement Concrete Res. 30: 1517–1525

Musa D and Mehmet B 2021 Alternative system design for high temperature solid particle erosion wear problem. Tribol. Lett. 69: 23

Michael P S, Amarendra K R, Dongming Z, Mitchell R D and Douglas E W 2015 Thermal conductivity and erosion durability of composite two-phase air plasma sprayed thermal barrier coatings. Surface Coat. Technol. 279: 44–52

Shun-Sen W, Guan-Wei L, Jing-Ru M, Qun-Gong H and Zhen-Ping F 2010 Effects of coating thickness, test temperature, and coating hardness on the erosion resistance of steam turbine blades. J. Eng. Gas Turbin. Power 132: 022102

Dongsheng W, Zongjun T, Lida S, Zhidong L and Yinhui H 2014 Effects of laser remelting on microstructure and solid particle erosion characteristics of ZrO2–7wt% Y2O3 thermal barrier coating prepared by plasma spraying. Ceram. Int. 40: 8791–8799

Ninham AJ and Ian H 1983 Proceedings of the 6th International Conference on Erosion by Liquid and Solid Impact, University of Cambridge: 50–51

Dong S W, Zong J T, Bin Y and Li D S 2012 Preparation and solid particle erosion behaviors of plasma-sprayed and laser-remelted ZrO2-7wt.% Y2O3 thermal barrier coatings. Journal 159: 191–197

Brian L and Michael S 1975 Microfracture beneath point indentations in brittle solids. J. Mater. Sci. 10: 113–122

Dongming Z and Robert A M 2000 Thermal conductivity and elastic modulus evolution of thermal barrier coatings under high heat flux conditions. J. Therm. Spray Technol. 9: 175–180

Khiam A K and Yanwei G 2000 Thermal properties of plasma-sprayed functionally graded thermal barrier coatings. Thin Solid Films 372: 104–113

Emil A, Elif E and Harley T J 2019 Grain boundary structure and migration in graphene via the displacement shift complete lattice. Acta Mater. 166: 67–74

Acknowledgements

We would like to thank Konya Technical University Coordinator ship of Scientific Research Projects.

Author information

Authors and Affiliations

Contributions

MD contributed to conceptualization, methodology, data processing visualization. Mehmet Bagci contributed to formal analysis, writing—original draft.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Demirci, M., Bagci, M. Failure mechanisms of interfacial coatings (MCrAlY+8YSZ) on high temperature solid particle erosion. Sādhanā 49, 163 (2024). https://doi.org/10.1007/s12046-024-02507-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-024-02507-x